Service Manual

Product spec and feature

2-10

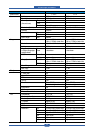

- SMPS Board & HVPS Board

These are integrated into a singe PBA. The Power Supply uses the 110VAC/220VAC supply voltage to

generate the DC Voltages used by the system. The SMPS has 3 output channels (+5V, +12V, +24V, +24VS) and

supplies the Main Board and the OPE Board.

The HVPS creates the high voltages (THV/MHV/Supply/Dev) used for the electrophotographic process. The high

voltage is created from the 24VS line from the SMPS. High Voltage output is supplied to the Toner, the OPC

Cartridge and the Transfer Roller.

- OPE Board

The Operation Panel is driven by its own internal program using the OPE MICOM chip separate from the Main

Board processor. Data is transferred using the UART Port in the Main Controller serially. This unit

consists of the MICOM, the Key Pad Matrix and the LCD.

- Toner Cartridge

The Toner Cartridge consists of integrated Exposure and Developer units. The Exposure Unit consists of the OPC

Drum and the Charge Roller, and the Developer Unit consists of the toner particles and its tank, the Supply Roller

and the Developer Roller.

- LSU (Laser Scanner Unit)

This is the core of the laser printer. It converts the video data received from the computer into an electrostatic

latent image on the surface of the OPC drum. This is achieved by controlling the laser beam and exposing the sur-

face of the OPC drum to the laser light. A rotating polygon mirror reflects the laser light onto the OPC and each

side of the mirror is one scan line. The OPC drum turns as the paper feeds to scan the image down the page.

The /HSYNC signal is created when the laser beam from LSU reaches the end of the polygon mirror and this sig-

nal is sent to the controller. The controller detects the /HSYNC signal to adjust the vertical line of the image on

paper. In other words after the /HSYNC signal is detected the image data is sent to the LSU to adjust the left mar-

gin on the paper.

- Toner Transfer

Toner is transferred from the OPC drum onto the paper using a PTL (Pre-transfer Lamp) and a transfer roller. The

PTL shines light onto the OPC, this reduces the electrical charge on the surface of the OPC

surface and improves the efficiency of the transfer.

The transfer roller transfers toner from the OPC drum to the paper.

Life span: Print over 100,000 sheets (at 15~30ºC)

- Fuser

This consists of a heat lamp, heat roller, pressure roller, thermistor and thermostat. By use of heat and pressure

toner is caused to melt and adhere to the paper surface in order to complete the printing process.