Service Manual

Product spec and feature

2-23

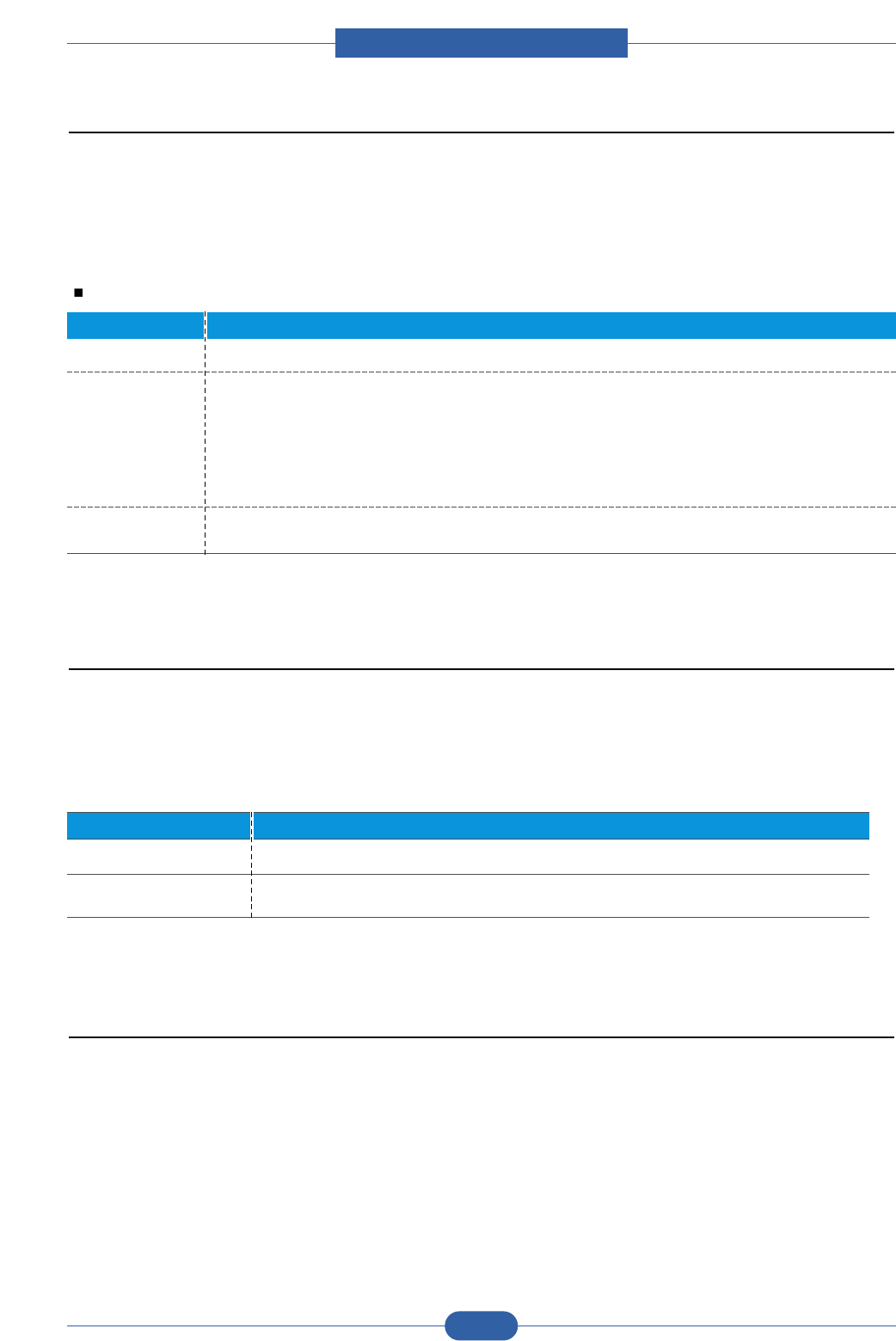

2.2.6.4 Fusing

The temperature of the heat roller's surface is detected according to the resistance value of the thermistor.

The thermistor resistance is measured using the A/D converter and thus the CPU can determine the

temperature of the heat roller. The AC power is controlled by comparing the target temperature to the value

from the thermistor. If the value from the thermistor is out of the controlling range while controlling the fusing

process, the error stated in the table occurs. (For the domestic model, the Q-PID method has been applied.)

Error Type

2.2.6.5 LSU

The LSU consists of the LD (Laser Diode) and the polygon motor control. When the printing signal occurs,

the LD is turned on and the polygon motor is enabled. When the light sensor detects the beam, Hsync occurs.

When the polygon motor speed becomes a normal, LReady occurs. If these two conditions are satisfied, the

status bit of the LSU controller register becomes 1 ant the LSU is judged to be ready. If the two conditions

are not satisfied, the error shown in the table below occurs.

Error Description

Open heat error When warming up, it has been lower than 68 °C over 25 sec

Lower heat error • Standby:

It has been lower than 100°C over 25 sec

• Printing:

- 2 consecutive pages: it has been lower than 145°C over 5 sec

- 3 consecutive page; it has been 40°C lower than the fixed fusing temperature over 4 seconds.

Over heat error It have been higher than 220°C over 3 seconds

Error Description

Polygon motor error When the polygon motor’s speed doesn’t become a normal

Hsync error The polygon motor’s speed is normal, but the Hsync signal is not created.

2.2.7 OPE PBA

The OPE board consists of various function keys and an LCD to display set status and operator messages.

A MICOM (HOLTEC HT48R50) and drives the LEDs and LCD. Communication between the OPE and the

CPU on the main board is serial (related signals are /Reset, TXD, and RXD).