Telect, Inc. • USA +1.509.926.6000 • Mexico +1.52.33.3836.3700

Poland +1.48.713.239.100 • UK +1.44.1489.889500 • www.telect.com

Copyright © 2002 Telect, Inc., All Rights Reserved

Page 2-7

6. Torque input BATT connections to 36 ft-lb (48.81 N•m).

7. In a similar fashion, for the input RTN —

a. Use a UL-approved crimping tool to attach a UL-approved, dual-hole 750/777.7 MCM compression lugs onto appropriate

RTN cables. Insulate lug barrels as required.

b. Clean RTN terminal plate and lugs with a nonabrasive, nonmetallic pad.

c. Lightly coat anti-oxidant electrical joint compound on lugs and RTN input terminal plates.

d. Use a

3

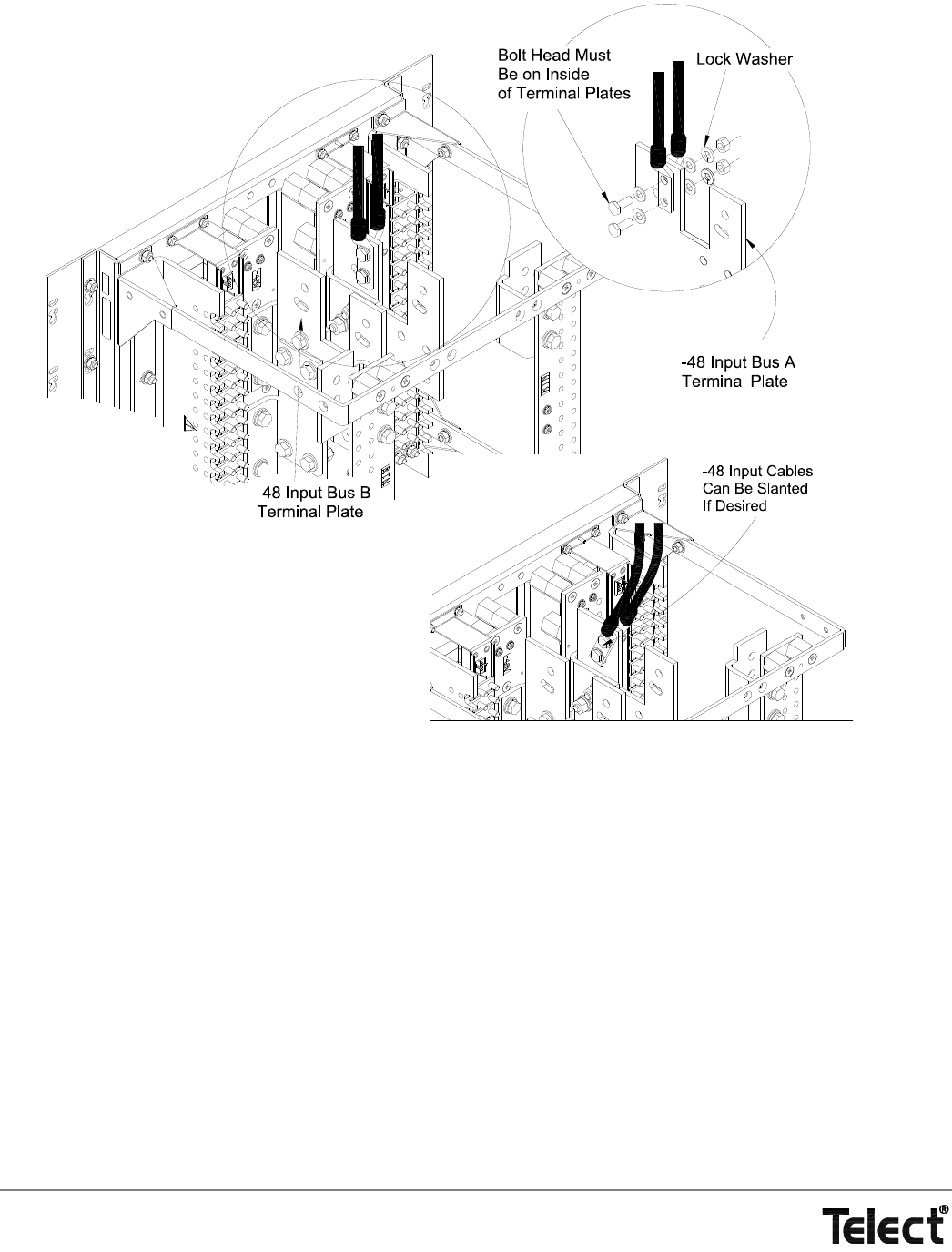

/8-16, grade 2 bolts, washers, and nuts (all provided) to secure the first pair of RTN cabling to the RTN input bus ter-

minal plate. (See the following illustration.)

• If two lugs are used, remember to attach lugs to opposite faces of the terminal plate. DON’T STACK LUGS on one side

of the terminal plate.

• Always route cables in a neat orderly manner to ensure that the cables exert no pulling or twisting forces on the input

and return terminal plates. DON’T ALLOW TERMINAL PLATES to support the weight of or to restrain the cable.