5-9

5

Specifications

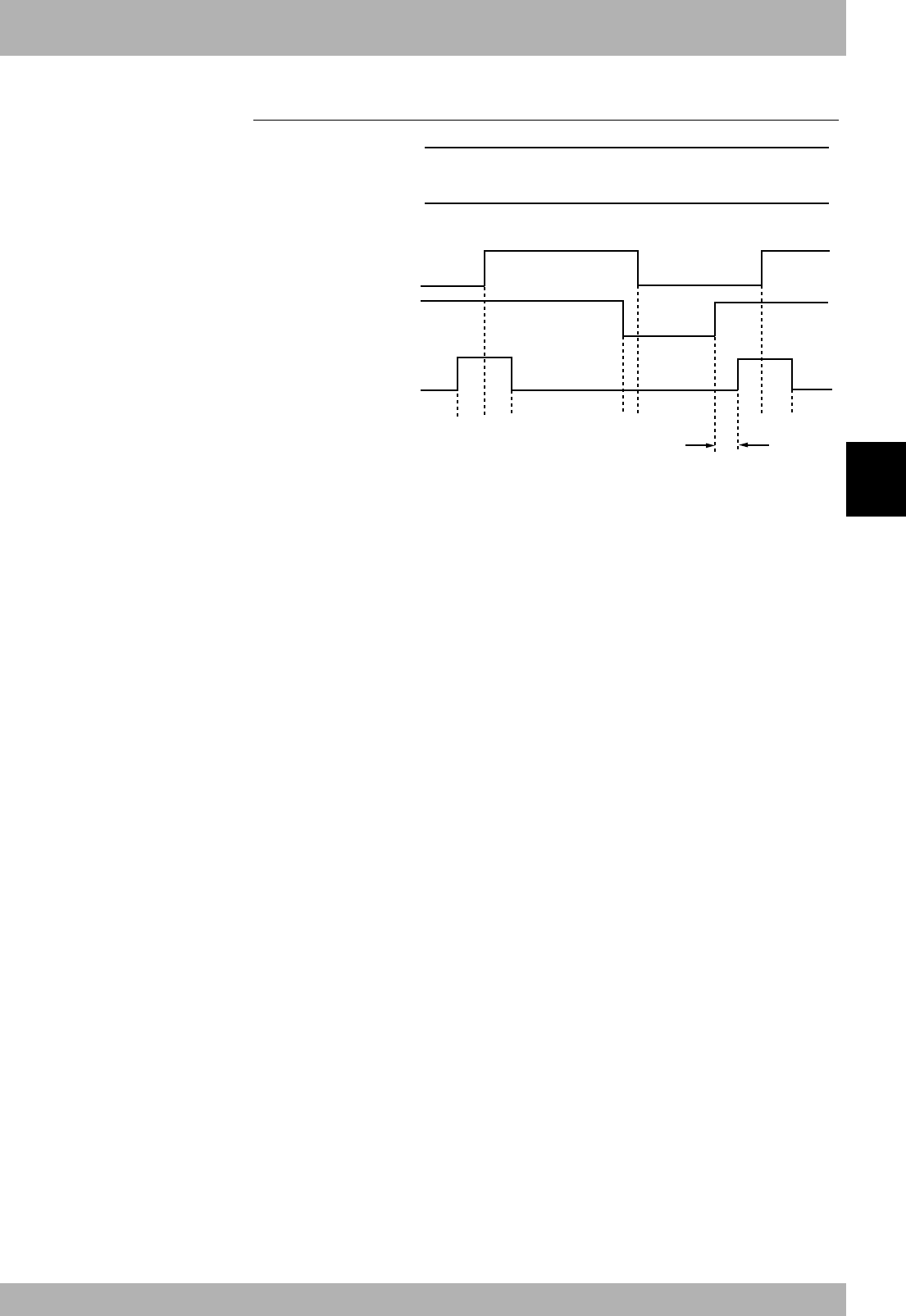

3. Dedicated input/output signal timing chart

3.4 Stopping with program interlock

a) b)

c) d) e) f) g) h) i)

on

on

off

on

off

on

off

on

off

off

RXn8:SO

(

10

)

AUTO mode status

output

RXn9:SO

(

11

)

Origin return complete

status output

RXnB:SO

(

13

)

Robot program execution

status output

RYn9:SI

(

11

)

Interlock input

RYnA:SI

(

12

)

Robot program start

input

100ms or more

Program execution process

a) Robot program start input ON is input

b) Robot program execution status output ON is output

c) After confirming that the robot program execution status output is ON, the start

input OFF is input

Program stop process using interlock input

d) Interlock input OFF is input

e) Robot program execution status output OFF is output

Program execution after stopping program with interlock input

f) Interlock input ON is input

g) Robot program start input ON is input

h) Robot program execution status output ON is output

i) After confirming that the robot program execution status output is ON, the start

input OFF is input

* The program will also stop when the emergency stop input OFF is input. In this case,

the emergency stop input status and alarm status output ON will be output, and the

servo ON status output OFF will be output. The servo ON process is required to start

the program again.

* When SAFE mode is enabled, dedicated inputs other than SI (00) and SI (11) might be

disabled depending on service mode parameter setting unless service mode input sig-

nal is set to ON with SI (02) in the CC-Link system.

c

CAUTION

• The dedicated input ON/OFF

process from the master station

PLC to the controller must be

carried out at an interval of

100ms or more. If the interval is

too short, the dedicated input may

not be recognized. (This also

applies to the same dedicated

input and differing dedicated

input intervals.)

• If dedicated outputs are provided

for the dedicated inputs from the

master station PLC to controller,

use them.