Overview

312776F 13

Overview

Usage

The Graco ProMix 2KS is an electronic two-component paint proportioner. It can blend most two-component solvent

and waterborne epoxy, polyurethane, and acid-catalyzed paints. It is not for use with “quick-setting” paints (those

with a potlife of less than 15 minutes).

• Can proportion at ratios from 0.1:1 to 50:1 in 0.1

increments with the wall mount fluid station.

• Has user selectable ratio assurance and can main-

tain up to +/-1% accuracy, depending on materials

and operating conditions.

• Models are available to operate air spray or

air-assisted systems with a capacity of up to 3800

cc/min.

• Color change options are available for low pressure

(300 psi [2.1 MPa, 21 bar]) air spray and high pres-

sure (3000 psi [21 MPa, 210 bar]) systems with up

to 30 color change valves and up to 4 catalyst

change valves.

NOTE: Optional accessories are available for in

field installation to achieve 30 colors.

Component Identification and Definition

See Table 1, FIG. 2, and FIG. 3 for the system components.

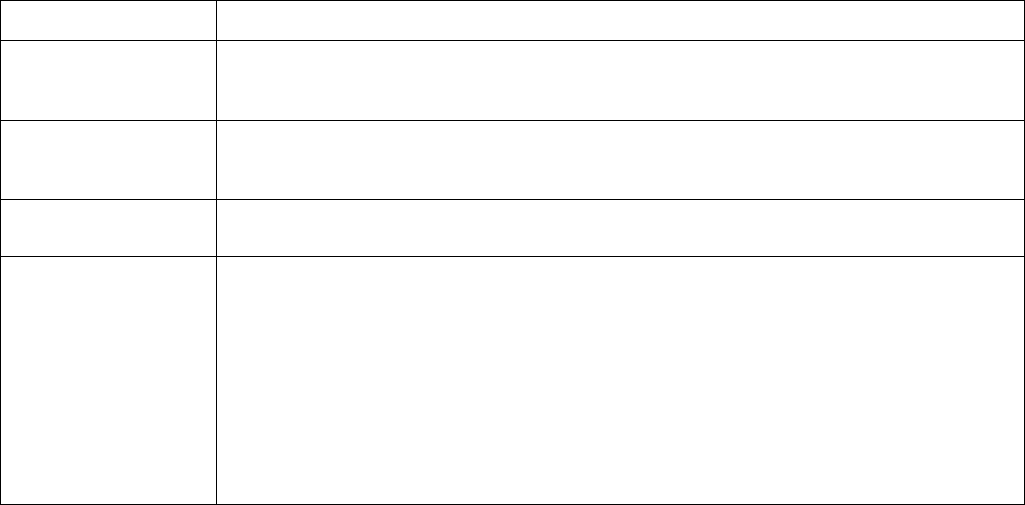

Table 1: Component Descriptions

Component Description

EasyKey (EK)

Used to set up, display, operate, and monitor the system. The EasyKey accepts 85-250

VAC, 50/60 Hz line power and converts that power to acceptable low voltage and optical

signals used by other system components.

Booth Control (BC)

Used by the operator for daily painting functions including: choosing recipes, initiating job

complete, reading/clearing alarms, and placing the system in Standby, Mix, or Purge

mode. It is typically mounted inside the booth or near the painter.

Fluid Station (ST)

Includes air control solenoids, flow switches, and mountings for the fluid flow meters and

the fluid manifold assembly. Its control board manages all proportioning functions.

Fluid Manifold (FM)

• Pneumatically Operated Dose Valves for component A and B

• Purge Valves for solvent and air purge

• Sampling Valves for calibrating the flow meters and performing ratio checks

• Shutoff Valves for component A and B to close their fluid passages to the mix mani-

fold, to allow for accurate calibration and ratio checks

• Mix Manifold, which includes the fluid integrator and static mixer.

Fluid Integrator is the chamber where component A and B align at the

selected ratio and begin to mix.

Static Mixer has 24 elements to uniformly blend the materials downstream

of the fluid integrator.