System Operation

312776F 47

5. The components are pre-mixed in the integrator,

then uniformly blended in the static mixer (SM).

NOTE: To control output from the static mixer to the

gun, install an optional fluid pressure regulator.

6. Components A and B are alternately fed into the

integrator as long as the gun is triggered.

7. If the gun is not triggered for two minutes, the sys-

tem switches to Idle mode, which closes off the mix

manifold dose valves.

8. When the gun is triggered again, the ProMix 2KS

continues the process where it left off.

NOTE: Operation can be stopped at any time by

pressing the Standby key or shutting off the

main power switch.

Table 5: Sequential Dosing Operation

Ratio = 2.0:1 Dose 1 Dose 2 Dose 3

A = 2

B = 1

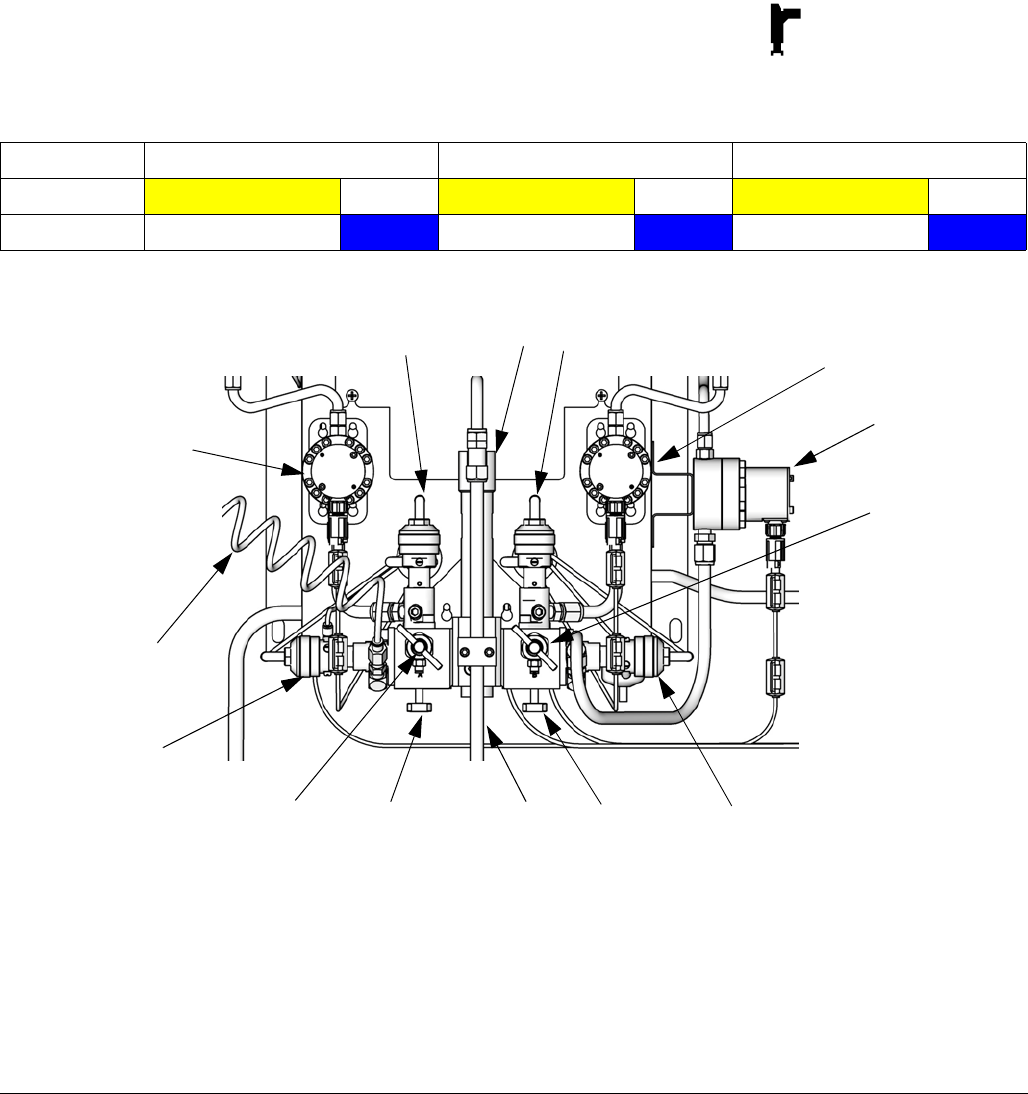

FIG. 51. Wall Mount Fluid Station, Sequential Dosing

TI12556b

MA

MB

DVB

MS

SPV

DVA

APV

SM

FI

SVA SVB

RVB

RVA

Key:

MA Component A Meter

DVA Component A Dose Valve

RVA Component A Sampling Valve

SVA Component A Shutoff Valve

MB Component B Meter

DVB Component B Dose Valve

RVB Component B Sampling Valve

SVB Component B Shutoff Valve

MS Solvent Meter (accessory)

SPV Solvent Purge Valve

APV Air Purge Valve

SM Static Mixer

FI Fluid Integrator

AT Air Purge Valve Air Supply Tube

AT