SECTION 4

MAINTENANCE

Purging the Nozzles

If the inkjet cartridge sits inactive for a period of time, ink may dry in the nozzles. Printing may not

remove these “ink plugs” from the nozzles. White streaks will then show up in the printed text or graphic.

In order to obtain better print quality, these ink plugs need to be forced out or purged. A Purge routine is

built into the printer. It can be accessed from the LCD panel on the Printer from the MENU key. If this

does not solve the problem then proceed as follows:

1. Wipe the printhead with a damp cloth as described in Section 4 "

Cleaning the Inkjet Cartridge".

2. Perform the Purge routine from the Printer by pressing the MENU key momentarily and then the +

key. Load media and press the ENTER key to purge. Repeat if necessary.

3. If the problem persists, replace the ink cartridge.

NOTE: For more information, refer to Section 5 - Troubleshooting Guide – HP Inkjet Print Cartridges.

Jams in the Printer

If a jam occurs; STOP the Printer. Up to 10 missed addresses can be recovered at the printer control panel.

(See Section 3 – Operating the Printer “

Print Recovery After a Jam”.

Some possible reasons for jamming are:

1. Feeding more than one piece of media (overlapping, double-feeding). Reset separation.

2. Damaged media, such a dog-eared (turn down corners).

3. Media that is not stiff enough may not be usable. Media that meets Postal stiffness requirements

for automated feeding is acceptable in the Envelope Imager 1.5/1.5+.

4. Envelopes that are caught under the flap of another envelope (nested) or stuck to one another may

cause jamming.

Removing Jammed Media

1. It may be necessary to move one or more of the printheads to gain access to the jammed media.

Take care in removing jammed media to prevent damage to the print heads. All pieces of the

jammed media must be removed from the feed path.

2. Follow the instructions in Section 3 – Operating the Printer “

Print Recovery a After Jam”.

Replacing the Sheet Separators

The sheet separators insure separation of the pieces as they are being fed. They do wear and must be

replaced from time to time. If you experience double sheet feeding and can not adjust the separators to

prevent it, they should be replaced. Replacement of the sheet separators is not difficult. Just follow the

steps below:

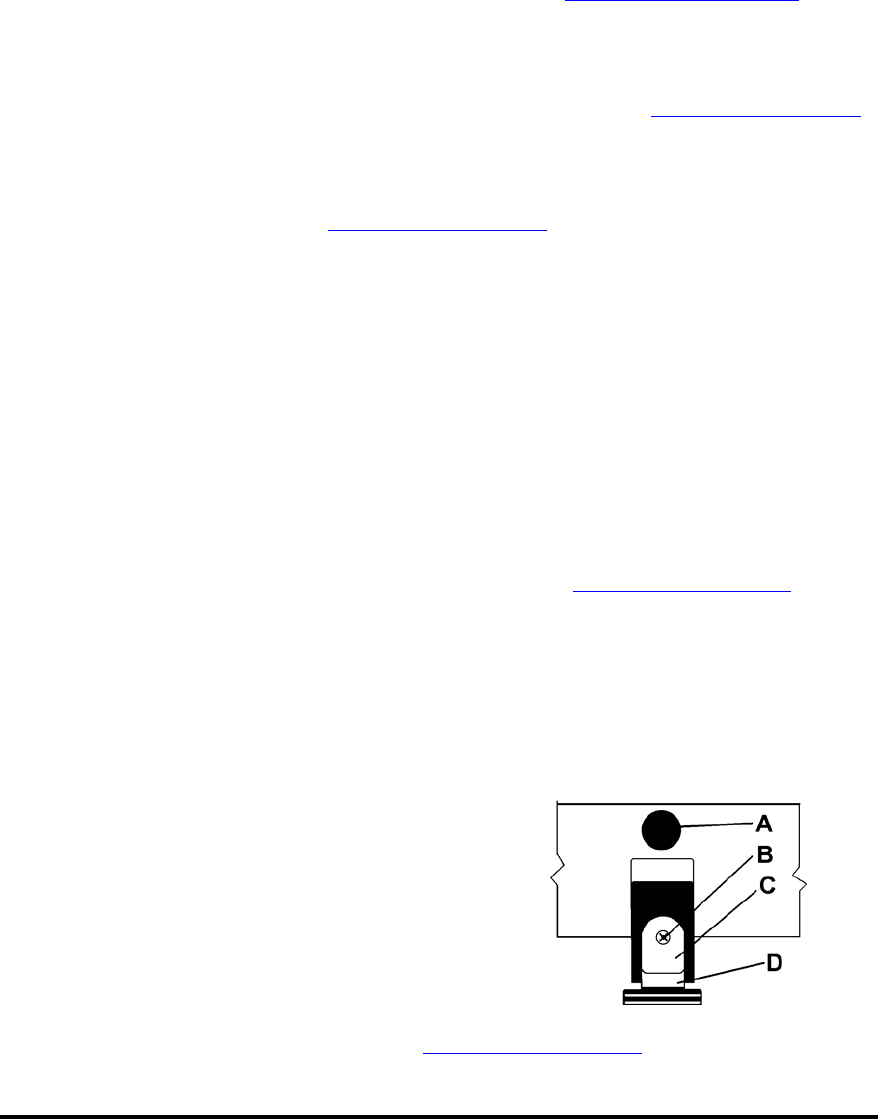

1. Turn off the Envelope Imager 1.5/1.5+ and unplug it from the power source.

2. Move the paper side guides to their maximum open

position, then release the separator-by loosening the

Separator Locking Knob [A].

3. Lower the separators so that they touch the feed roller.

4. Remove the screw [B] and the separator support plate

[C.] Then remove the separator [D] by prying it out of

the holder.

5. Install a new separator in place and replace the separator

support plate and screw.

6. Adjust the separators. See the section titled “

Setting up the Feed System”.

Envelope Imager 1.5/1.5+ Operations Rev. 6/7/2007

41