Intel

®

E8500/E8501 Chipset North Bridge (NB) and eXternal Memory 27

Bridge (XMB) Thermal/Mechanical Design Guide

NB Reference Thermal Solution #1

6.5.1 Heatsink Orientation

Since this solution is based on a unidirectional heatsink, mean airflow direction must be aligned

with the direction of the heatsink fins.

6.5.2 Extruded Heatsink Profiles

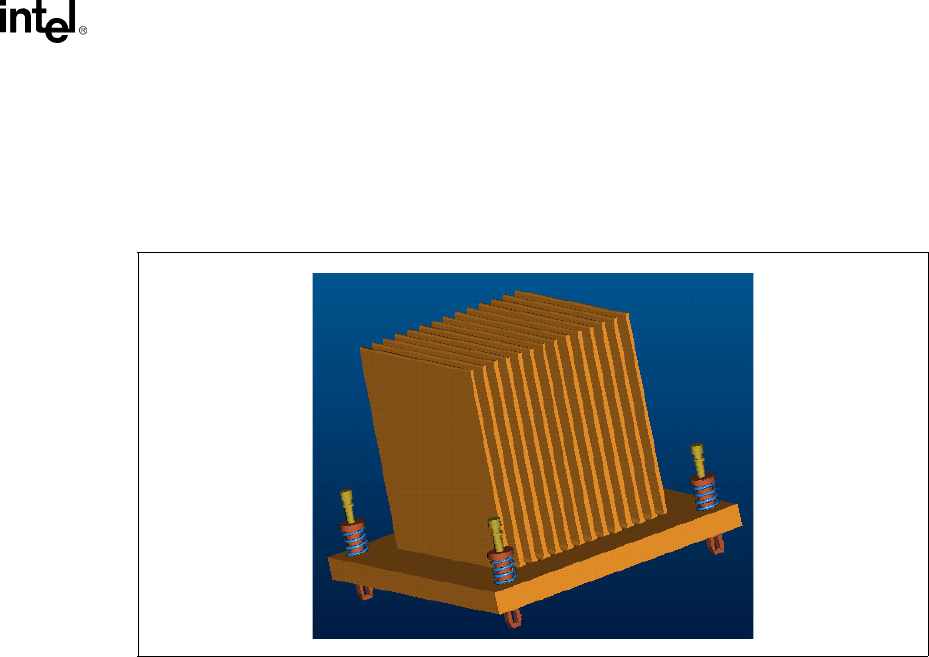

The reference NB thermal solution uses an extruded heatsink for cooling the chipset NB.

Figure 6-5 shows the heatsink profile. Appendix A lists a supplier for this extruded heatsink. Other

heatsinks with similar dimensions and increased thermal performance may be available. Full

mechanical drawing of this heatsink is provided in Appendix B.

6.5.3 Mechanical Interface Material

There is no mechanical interface material associated with this reference solution.

6.5.4 Thermal Interface Material

A TIM provides improved conductivity between the die and heatsink. The reference thermal

solution uses Chomerics THERMFLOW* T710, 0.127 mm (0.005 in.) thick, 38.5 mm x 38.5 mm

(1.5 in. x 1.5 in.) square.

Note: Unflowed or “dry” Chomerics THERMFLOW T710 has a material thickness of 0.005 inch. The

flowed or “wet” Chomerics THERMFLOW T710 has a material thickness of ~0.0025 inch after it

reaches its phase change temperature.

6.5.4.1 Effect of Pressure on TIM Performance

As mechanical pressure increases on the TIM, the thermal resistance of the TIM decreases. This

phenomenon is due to the decrease of the bond line thickness (BLT). BLT is the final settled

thickness of the thermal interface material after installation of heatsink. The effect of pressure on

Figure 6-4. First NB Heatsink Assembly