Optra Es Special Media Printer

89

Maintenance Procedures

If the print quality begins to degrade when printing sheets of vinyl labels, we suggest you follow the

three cleaning steps below:

1 Print 5 sheets of paper.

2 Wait approximately 5 seconds.

3 Print 5 more sheets of paper.

To maintain printer feeding reliability, repeat this cleaning process every time you replace the print

cartridge, more often with some media. Failure to follow maintenance procedures could cause

jamming, poor print quality, feeding problems, and fuser problems.

Summary

Your printer can accept a wide range of paper or card stock weights, but materials either too light or

too heavy can cause paper handling and print quality problems. Heavier weight materials can cause

fusing problems because of the mass of material the fuser must heat quickly. Heavy materials may

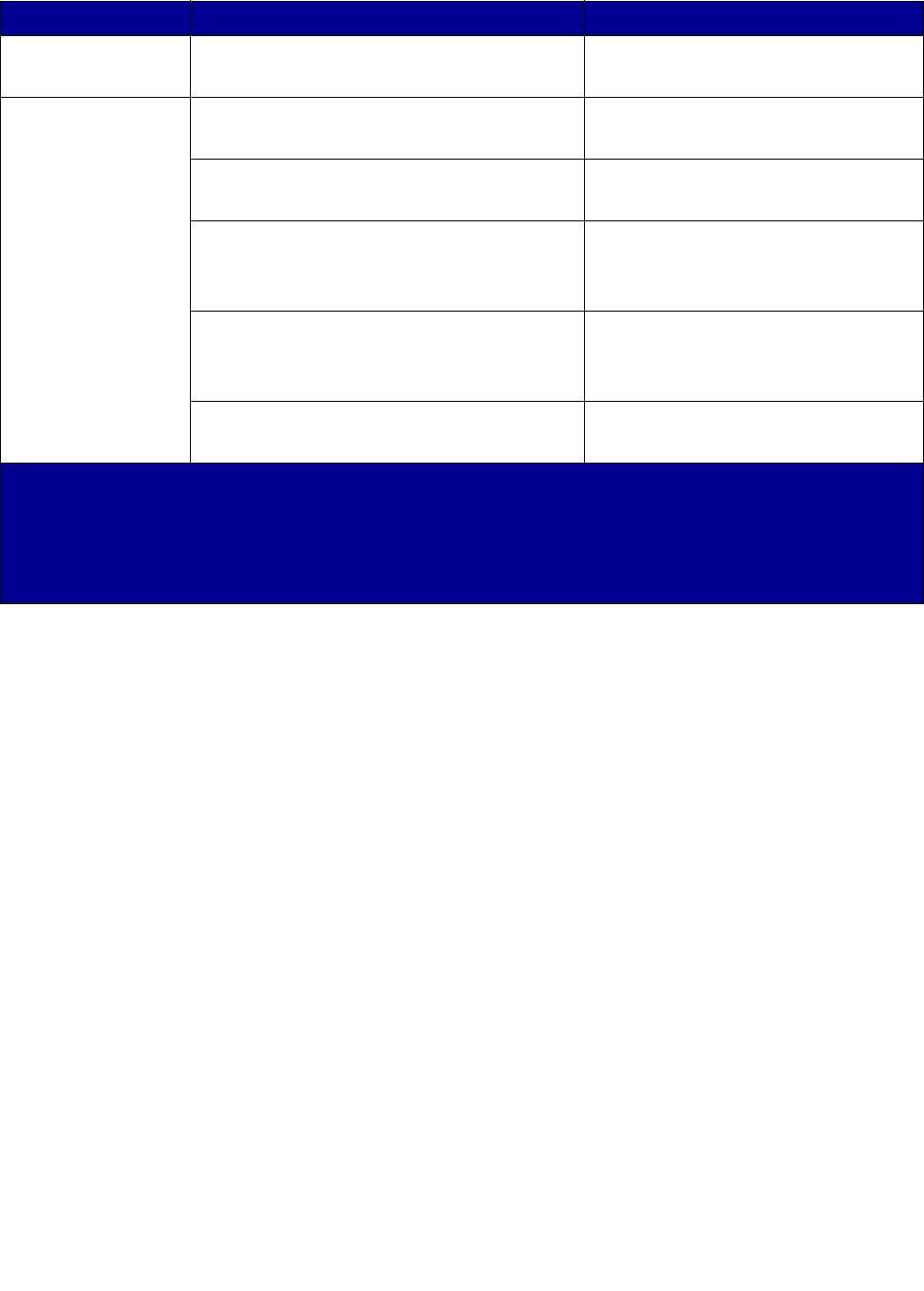

Media Weights

Print Media Type Basis Weight

Paper

1

Xerographic or Letterhead

75 - 90 g/m

2

(20 - 24 lb)

Labels

2

Paper

120 - 180 g/m

2

(32 - 48 lb)

Vinyl

3

260 - 300 g/m

2

(78 - 92 lb liner)

Dual Web Forms

Pressure sensitive area

Paper base

4

140 - 180 g/m

2

75 - 131 g/m

2

Integrated Forms

Pressure sensitive area

Paper base

4

140 - 175 g/m

2

75 - 135 g/m

2

Tag

75 - 163 g/m

2

(50, 74, 100 lb Tag)

1

Paper lighter than 75 g/m

2

(20 lb) is not stiff enough to feed properly, causing paper jams and possibly

requiring a service call.

2

Feed labels only when temperatures range from 18 to 24°C (65 to 75°F) with relative humidity of 40 to 60%.

3

Grain short recommended.

4

Grain long recommended.