9 - 5 9 - 5

MELSEC-Q

9 LOADING AND INSTALLATION

(3) Fail-safe measures against failure of the PLC

Failure of a CPU module or memory can be detected by the self-diagnosis

function. However, failure of I/O control area may not be detected by the CPU

module.

In such cases, all I/O points turn ON or OFF depending on a condition of

problem, and normal operating conditions and operating safety cannot

sometimes be maintained.

Though Mitsubishi PLCs are manufactured under strict quality control, they may

cause failure or abnormal operations due to unspecific reasons. To prevent the

abnormal operation of the whole system, machine breakdown, and accidents,

fail-safe circuitry against failure of the PLC must be constructed outside the PLC.

Examples of a system and its fail-safe circuitry are described below:

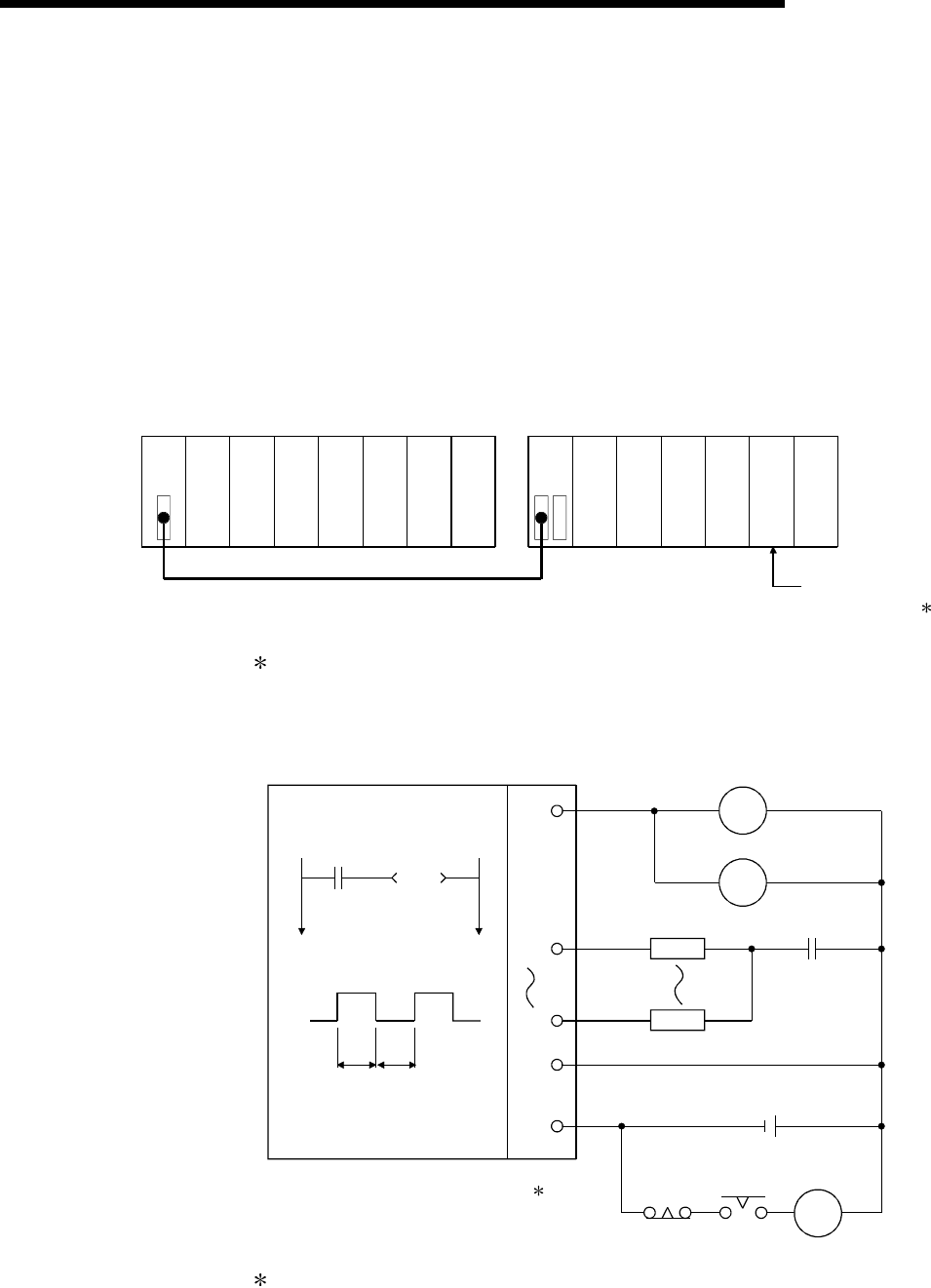

<System example>

Power supply

module

CPU module

Input 16 points

Vacant

Input 16 points

Input 16 points

Input 16 points

Output 16 points

Y80 to Y8F

Output 16 points

Output 16 points

Output 16 points

Output 16 points

Output module for

fail-safe purpose 1

Power supply

module

1: The output module for fail-safe purpose should be loaded in the last slot of

the system. (Y80 to Y8F in the above system.)

<Fail-safe circuit example>

Internal program

SM412

T1

ON delay timer

1s

T2

OFF delay timer

1s

L

L

MC

T2T1

+

-

24V DC

Y80

Y81

Y8F

24V

0V

Y80

Y80

External load

0.5s0.5s

CPU module

MC

Output module

2

2: Y80 repeats turning ON and then OFF at 0.5s intervals.

Use a no-contact output module (transistor in the example shown above).