Maintenance and Repair

to the charger and insert it into the charge socket that is just below your robot’s Main

Power switch. The LEDs on the charger indicate charge status, as marked on its case.

It takes fewer than 12 hours—often just a few hours, depending on the level of

discharge—to fully charge a battery using the accompanying charger (roughly, three

hours per volt per battery). Although you may operate the robot while recharging, it

restricts the robot’s mobility.

Automated Docking/Charging System

The automated docking/charging system accessory optimally conditions power to

charge the three 21-Ahr, 12 VDC lead-acid batteries (6 A charging current max) and

provides sufficient power (up to 5A) for operation of all onboard systems.

The charging mechanism and onboard power conditioning circuitry can be retrofitted to

all Pioneer 3 and some Pioneer 2 and PeopleBot robots. All require return to the factory.

Alternative Battery Chargers

The center post of the charger socket is the positive (+) side of the battery; the case is the

negative (-) side. A diode protects against the wrong charger polarity. Nonetheless, if

you choose to use an alternative battery charger, be sure to connect positive to positive

and negative to negative from charger to robot.

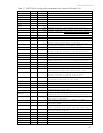

Figure 19. Loosen the AT drive belt retainer

screws first.

An alternative AC to DC

converter/battery charger should

sustain at least 0.75A at 13.75 to

14 VDC per battery, and not more

than 2-2.5 amperes per battery.

The High-Speed Charger

accessory, for example, is a four

ampere charger and should be

used with at least two of the

standard batteries.

An alternative charger also should

be voltage-and current-limited so

that it cannot overcharge the

batteries.

TIGHTENING THE AT DRIVE BELT

Occasionally, particularly after

heavy use, the Pioneer 3- or 2-

AT drive belts that mechanically

link the front and rear motors on

each side will loosen and slip,

resulting in a load popping

noise. To start, use a 3mm hex

key to loosen, but not remove,

the three screws on the side of

the robot near the front wheel.

One screw is partly behind the

wheel, so with our parts kit, we

included a 3mm hex key with a

shortened “L” section to fit

behind the wheel.

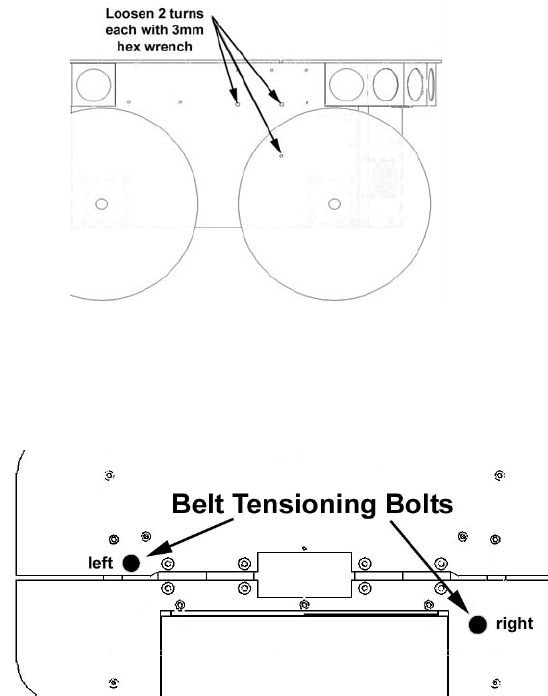

Figure 20. Locations of Pioneer 2- and 3-AT's belt-

tensioning bolts

62