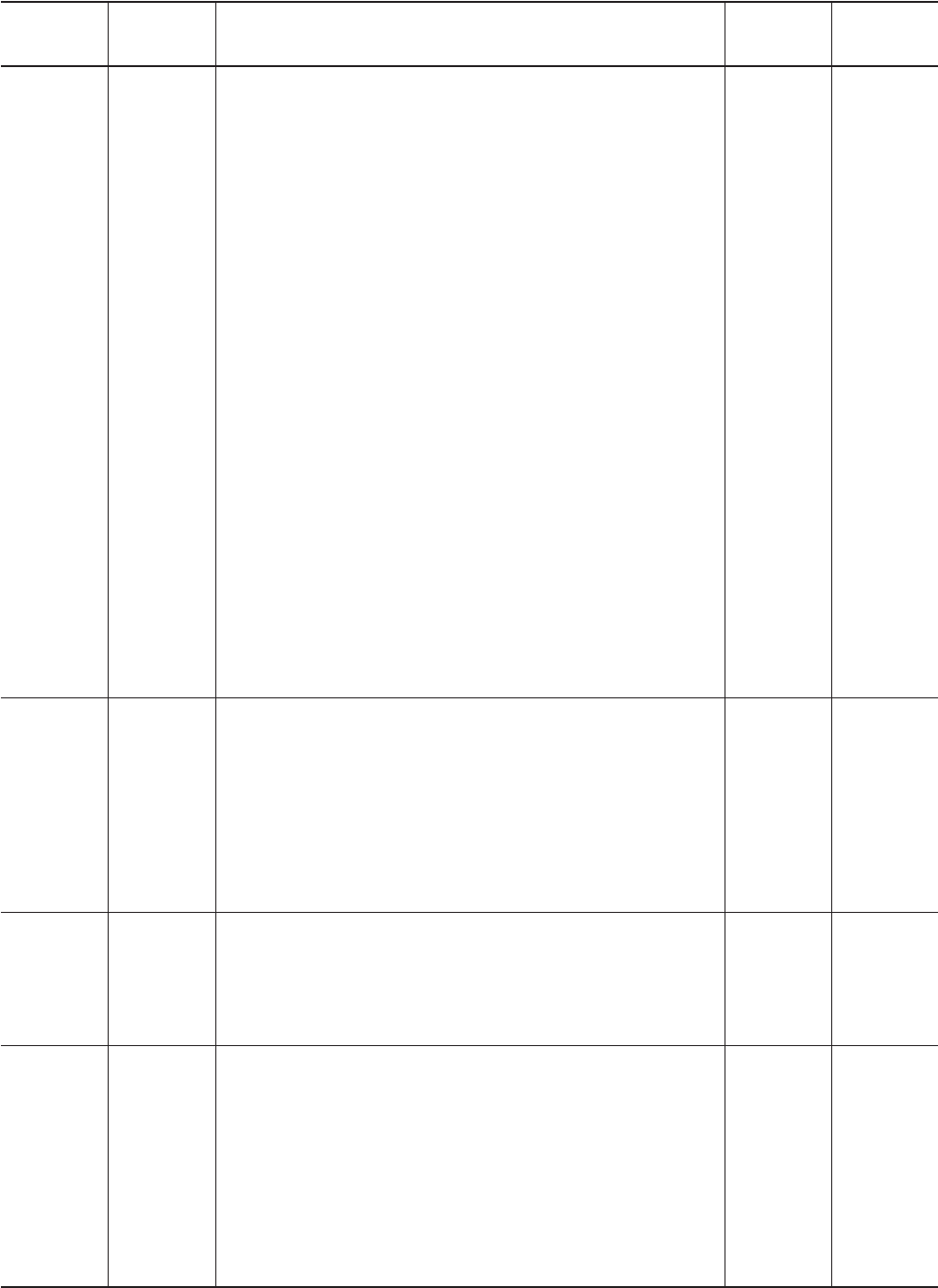

55

4 User's Reference

Default

value

Setting

range

FunctionSubmenu

Top

menu

INK

CONTROL

EMPTY

MODE

FILL INK

PUMP UP

HEAD WASH

CHANGE

INK SET

[EMPTY

MODE]

LATER/

PROMPT

[CHANGE

INK SET]

PIG.

CMYKLcLm/

PIG.

CMYKOrGr/

DYE

CMYKLcLm/

LATERWhen replacement of the ink cartridge becomes necessary while

printing is in progress, this setting determines whether printing

continues or pauses.

This setting is used when the ink cartridge cannot be changed immedi-

ately during printing, such as during unattended operation at night.

[LATER] causes printing to continue without pause even if ink refilling

becomes necessary. Printing continues with the small amount of ink

remaining, so the printed image may become faint as the ink runs out.

In general, it should possible to perform about 1 m

2

(10 ft

2

) of printing

once this message appears, although the actual varies widely according

to the amount of ink needed for the particular image. Printing is

continued only for the data currently being printed. Operation stops

after one image is output.

[PROMPT] causes operation to pause immediately when the ink

cartridge needs to be changed. Printing is resumed by replacing the

cartridge and pressing the [PAUSE] key. Please note, however, that the

colors of an image in progress may no longer be perfectly matched if

the unit is allowed to remain paused for two or three hours before

resuming printing.

[FILL INK] : Refills the printing heads with ink. Normally there is no

need to do this, because refilling is automatic.

[PUMP UP] : Drains ink from the printing heads.

[HEAD WASH] : This washes the printing heads with optionally

available cleaning cartridges. For more information, see "3-7 When

Moving the Unit... ."

[CHANGE INK SET] : Performs the [HEAD WASH] and [FILL INK]

operations.

This is used when switching the ink type. Before running this, choose

the type of ink to be used after the change.

For more information, see "3-4 Changing the Type of Ink."

BIDIRECTION

Correction

value when

shipped

from the

factory

This adjusts for slippage when performing bidirectional printing.

This must be readjusted when you have replaced the material with a

different type or adjusted the head height.

[TEST PRINT]: This menu is for verifying the adjustment.

[ADJUST]: This sets the correction value.

[ADJUST (HS)]: This sets the correction value for when in the high-

speed mode.

For more information, see "2-6 Printing -- Making Corrections for

Printing -- Bidirectional Correction."

TEST PRINT

ADJUST

ADJUST(HS)

[ADJUST]

-15 to +15

(In steps of 1)

[ADJUST

(HS)]

-30 to +30

(In steps of 1)

CARIBRATION 0%This corrects for errors in the amount of feed of the grit rollers due the

type of material.

Be sure to make this setting when you have replaced the material with

a different type.

Make this setting again when horizontal stripes are plainly visible on

printing results.

[TEST PRINT]: This menu is for verifying the adjustment.

[ADJUST]: This sets the correction value.

For more information, see "2-6 Printing -- Making Corrections for

Printing -- Feed Correction."

TEST PRINT

ADJUST

-2.0% to

+2.0%

(In steps of

0.05%)

HIGHSPEED

MODE

DISABLEIf you want to speed up printing time, choose [ENABLE]. When this is

set to [ENABLE], high-speed printing is performed, but only when the

printing mode is PHOTO (HS-PHOTO) or SUPER (HS-SUPER).

For more information, see "2-6 Printing Setting the Printing Mode

When You Want to Speed up Printing."

— ENABLE/

DISABLE