Section 4. Cleaning and Maintenance

Page 4-2 PN 9001105 Rev. A SATO M-84PRO

NOTE: The PRINT potentiometer adjustment will affect the darkness in all of the

command code speed ranges, i.e. if the PRINT potentiometer is adjusted for

lighter print, the darkness will be lighter in all speed ranges selected by the

command code.

PRINT SPEED

The other method of controlling print quality is by controlling the speed at which the label is

printed. This adjustment is made only on an individual label basis using the Print Speed

command code. For more details on this command, see the “e” and PRO 3Printer

Programming Reference. Changing the print speed allows the user to control the amount of

time allowed for print element cooling before the media is stepped to the next print position. It

is especially critical when printing “ladder” bar codes (bar codes printed with the bars parallel

to the print line). When printing a “ladder” bar code, it is important to allow the head to cool

sufficiently before stepping to the next position. If it does not have sufficient time to cool, the

bar will be “smeared” on the trailing edge.

The Print Speed can be set using the LCD panel or with the Print Speed software command.

The software command will override the any setting entered using the LCD panel.The other

method of controlling print quality is by controlling the speed at which the label is printed.

This adjustment is made only on an individual label basis using the Print Speed command

code. For more details on this command, see the “e” and PRO Printer Programming

Reference.

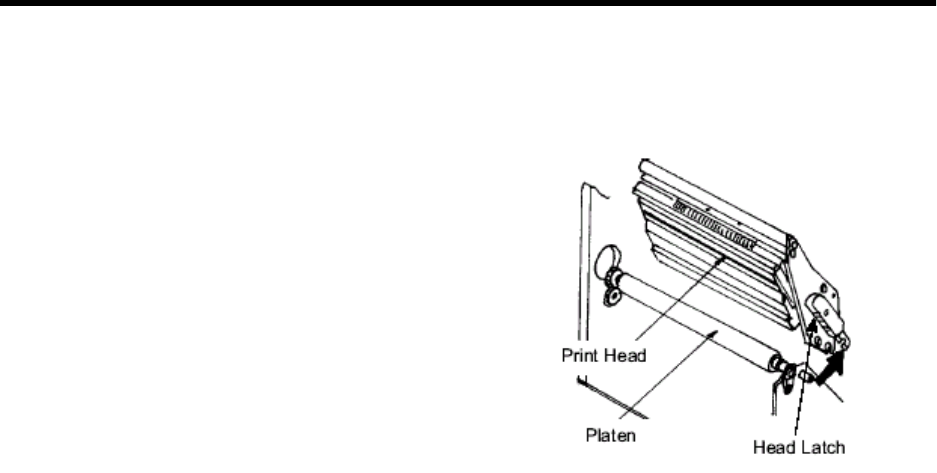

CLEANING THE PRINT HEAD, PLATEN AND ROLLERS

Supplies needed: SATO SA070 Cleaning Kit

Cleaning the Print Head

1. Turn the printer off and remove the

power cable.

2. Open the Top and Side Access Door.

3. Open the Print Head Assembly by

rotating the Head Latch toward the

back of the printer. The Print Head

Assembly is spring-loaded and will

automatically open as soon as the

Head Latch is disengaged.

4. Remove the ribbon.

5. Apply SATO Thermal Print Head

Cleaner to a cotton swab.

6. The Print Head faces downward

along the front edge of the assembly.

Pass the end of the dampened swab along the epoxy ridge that runs the entire width of the

Print Head.

7. Check for any black coloring or adhesive on the swab after cleaning.

8. Repeat if necessary until the swab is clean after it is passed over the head.

Head Cleaning

TBA