Section 4. Cleaning and Maintenance

SATO M-84PRO PN 9001105 Rev. A Page 4-3

9. The head should be cleaned at least every time the ribbon is changed and more often in

dusty environments.

Cleaning the Platen and Rollers

1. Turn the printer off and remove the

power cable.

2. Open Top and Side Access doors.

3. Open the Print Head Assembly by

rotating the Head Latch toward the

rear of the printer. The Print Head

Assembly is spring-loaded and will

automatically open as soon as the

Head Latch is disengaged.

4. Unlatch the Label Hold-Down by

lifting up on the latch lever

(immediately below the green PUSH tab.

5. Apply SATO Thermal Print Head Cleaner to one of the cotton swabs.

6. The Platen is the rubber roller directly below the Print Head. It should be cleaned of any

ribbon or label residue.

7. A pair of Label Feed Rollers are used to assist in label feeding at high print speeds. One

located in the bottom of the Label Hold-Down and the other directly underneath it in the

label feed path. They should be cleaned of any label residue or foreign material.

8. Repeat if necessary. The platen and rollers should be cleaned whenever foreign matter

such as dust or adhesive is present.

9. Close the Label Hold-Down until it latches in place.

10. Close the Print Head by rotating the Head Latch Lever down and towards the front until it

latches in place.

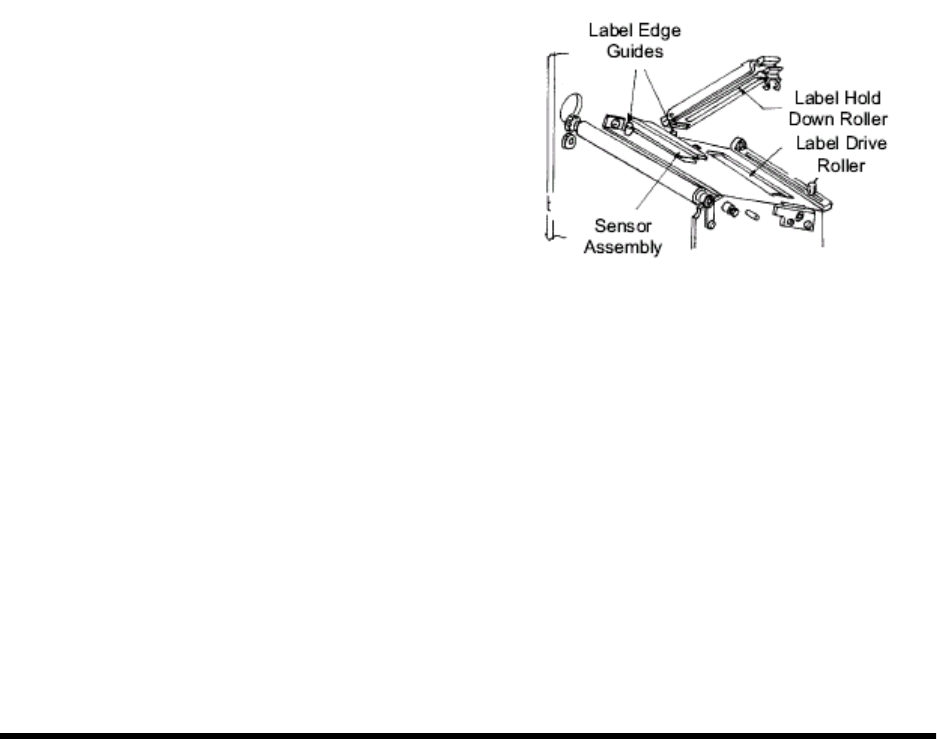

CLEANING THE LABEL EDGE SENSORS

There are two sensors that are used to control the positioning of the label. One is a

transmissive see-thru sensor that detects the edge of the label by looking through the backing

paper which is translucent and detecting the presence of the opaque backing. The other is a

reflective sensor that detects the light reflected from the bottom of the label liner. When a

printed black Eye-Mark passes through the beam, the light is no longer reflected back to the

sensor detector, indicating to the printer that it should use this position as the start of a new

label. When dust, dirt or other foreign matter interferes with the light path of either of these

sensors, the results is erratic label positioning. These sensors should be cleaned regularly, at

least every two rolls of labels. They are both located on an adjustable assembly in the throat of

the printer between the Label Hold Down and the Print Head.

Supplies Needed: SATO SA070 Cleaning Kit

1. Turn the printer off and remove the power cable.

2. Open the Top and Side Access doors.