EPSON Stylus C63/64/83/84 Revision A

Disassembly and Assembly Disassembly 17

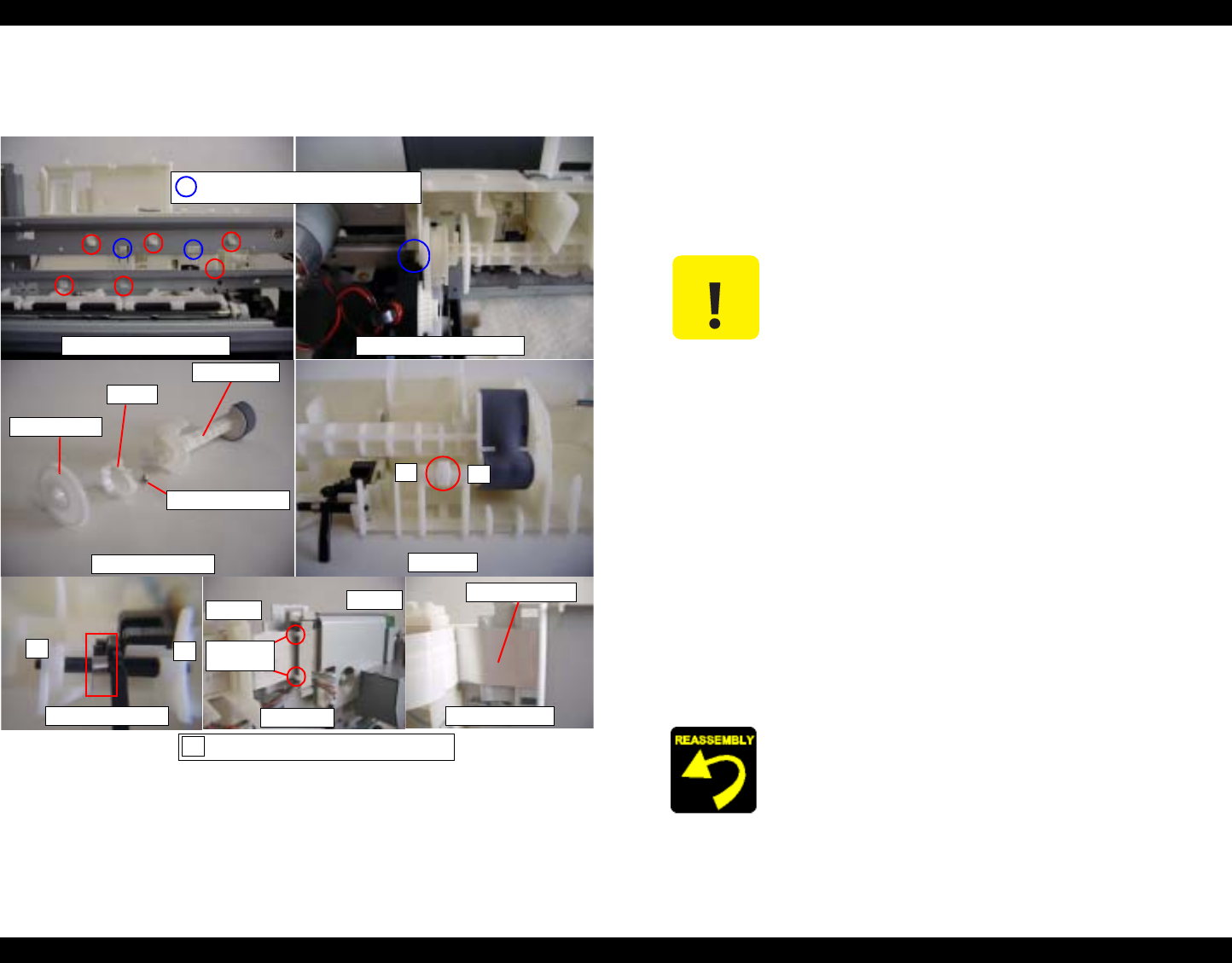

1.3.4 Holder shaft unit removal

o External view

Figure 1-5. Holder shaft unit removal

o

Part/Unit that should be removed before removing Holder shaft unit

Housing (Right/Left/Frame) / ASF unit

o Removal procedure

1) Disconnect Panel board connector cable from the connector on main board,

and remove Panel board.

2) Remove Clamp core from [Mounting Plate, M/B] and disconnect Head FFC,

CR motor connector cable and PE sensor cable from the connector on main

board. Then, release Head FFC and CR motor connector cable from Holder

shaft unit.

3) Release Change lever toward the backside of the printer by the tweezer, and

move CR unit to the leftmost side (far side).

4) Remove Holder shaft unit from main frame as belows.

Step1) Push two hooks of LD roller shaft holder, and pull Holder shaft unit

upward slightly from main frame.

Stepe2) Move Pump unit to home position side slightly while holing the whole

of Holder shaft unit, and pull the bottom of the unit toward the

backside of the printer.

5) Remove LD roller shaft along with Clutch mechanism from LD roller shaft

holder.

6) Remove the Spur gear 36.8 from LD roller shaft.

7) Remove Extension spring, 0.143, and remove Clutch from LD roller shaft.

8) Release one hook for securing PE sensor board, and push the sensor board from

the side contacting main frame by the tweezer.

9) Release Torsion spring 0.22 for PE detection levers, and remove the lever from

LD roller shaft holder.

Holder shaft unit (Backside)

Holder shaft unit (Front side)

Idle roller

LD roller shaft unit

Torsion spring 0.22

Shield Plate FFC

Cramp core

HP side

Far side

Shield Plate FFC

Dowel of

cramp core

Spur gear 36.8

Clatch

Tension spring 0.143

LD roller shaft

This marking is the hook/protrusion

for releasing Holder shaft uni.

1

2

1

2

This marking is the order of assembling.

1

C A U T I O N

o Shield plate FFC on Head FFC is pasted on [Mounting

Plate, M/B]. Therefore, you have to remove Shield plate

FFC with Head FFC.

o When assembling PE detection lever & sensor board to LD

roller shaft holder,

n Make sure to set Torsion spring 0.22 for PE detection

lever to the suitable position.

n Make sure that PE detection lever moves smoothly.

n Make sure that PE sensor board is correctly fixed by the

hook of LD roller shaft holder.