EPSON Stylus C63/64/83/84 Revision A

Disassembly and Assembly Disassembly 33

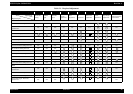

1.3.14 PF motor removal

o External view

Figure 1-26. PF motor removal

o

Part/Unit that should be removed before removing PF motor

Housing (Right/Left/Frame) / ASF unit / Circuit board / PS board / CR unit with

Front frame / Paper eject roller / Paper guide front / Housing (Lower)

o Procedure of removal

1) Remove Idle roller assy. & Compression spring, 1.13 for keeping PF timing belt

tension.

2) Remove four nuts for securing PF motor to main frame, and remove the motor.

Idle roller assy. (Idle roller & holder)

PF timing belt

Compression spring, 1.13

Screw type : HEXAGON NUT, NORMAL, M3

Order of tightening : First

Thghtening torque : 6

±

1 kgf.cm

Screw type : HEXAGON NUT, NORMAL, M3

Order of tightening : Second

Thghtening torque : 6

±

1 kgf.cm

Screw type : HEXAGON NUT, NORMAL, M3

Order of tightening : Third

Thghtening torque : 6

±

1 kgf.cm

Screw type : HEXAGON NUT, NORMAL, M3

Order of tightening : 4th

Thghtening torque : 6

±

1 kgf.cm

PF motor

Compression spring, 1.53

(This spring is only here)

Spacer, Insulator

Insurator, Motor, PF

C A U T I O N

o When removing PF motor from main frame, do not damage

the pinion gear of PF motor.

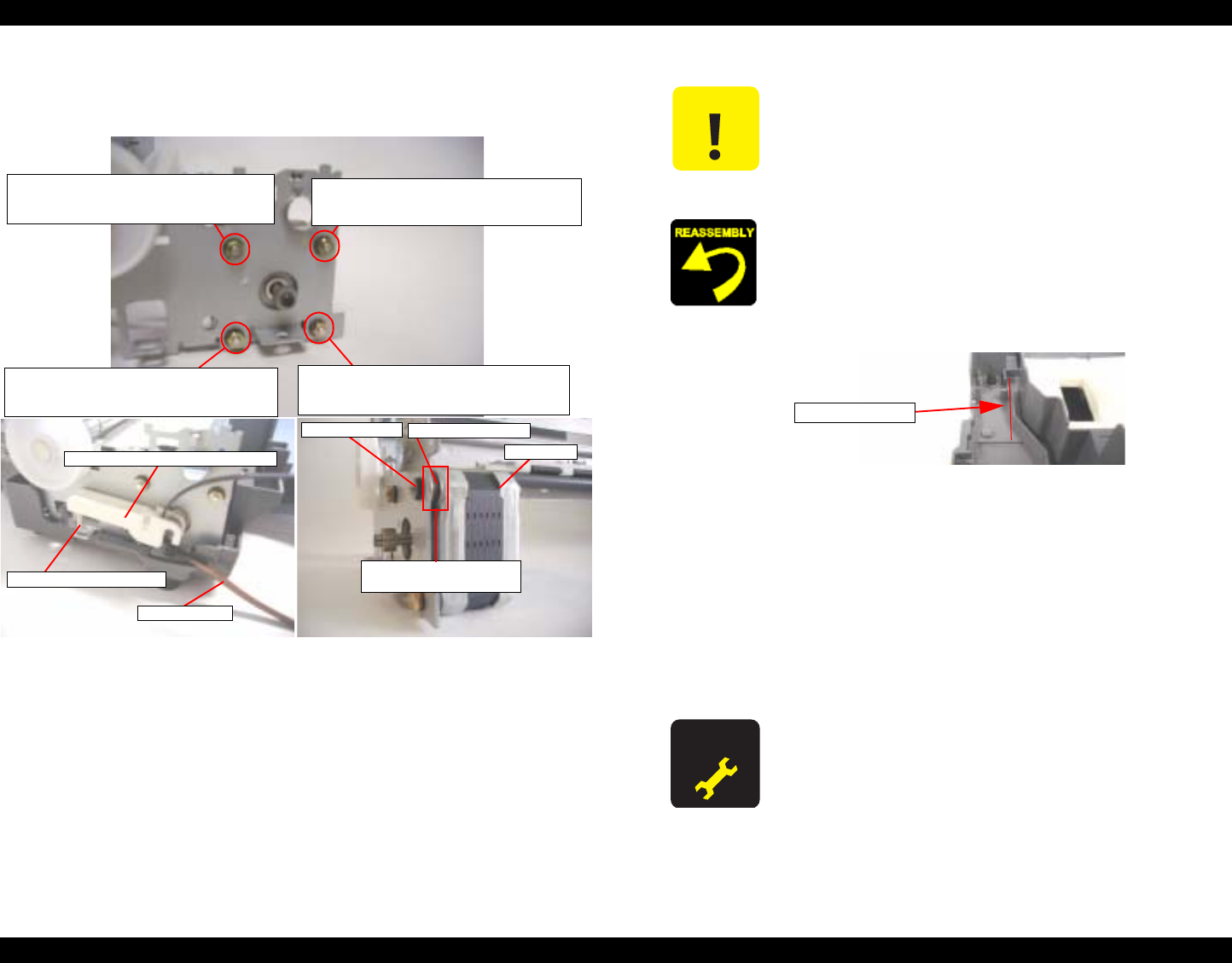

o When assembling PF motor to main frame,

n Do not damage PF motor pinion gear with main frame.

n Make sure to place PF motor connector cable to

Housing (Lower) properly before put printer

mechanism on Housing (Lower).

Figure 1-27. Placement position of PF motor cable

n

Make sure to connect PF motor connector cable to

connector (CN6) on main board by the tweezer.

n Fasten four nuts for securing PF motor to main frame in

the order/tightening torque indicated in the figure.

n Make sure that there is no gap between [Spacer,

Insulator] and frame main.

n Make sure not to lost Compression Spring, 1.53.

A D J U S T M E N T

R E Q U I R E D

o When PF motor is removed or replaced with new one, the

following adjustment must be performed in the order below.

1) Top margin adjustment

2) PF adjustment

3) Bi-d adjustment

4) Head angular adjustment

5) 1st dot adjustment

6) PW sensor adjustment (Only for SC83/84)

Placement position