Printing specialty documents

Tips on using letterhead

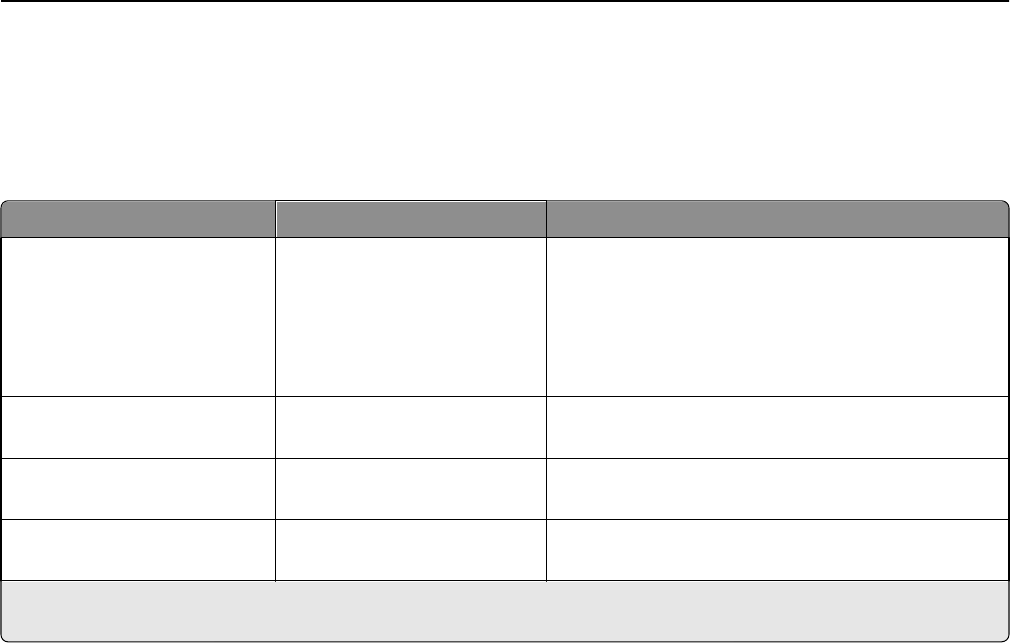

Source or process Print side Paper orientation

• Standard 550‑sheet tray

• Optional 550‑sheet tray

• Optional 2,000‑sheet tray

• Optional 550‑sheet specialty

media drawer

Preprinted letterhead design is

placed faceup.

The top edge of the sheet with the logo is placed at the

front of the tray.

Duplex (two‑sided) printing

from trays

Preprinted letterhead design is

placed facedown.

The top edge of the sheet with the logo is placed at the

back of the tray.

Multipurpose feeder (simplex

printing)

Preprinted letterhead design is

placed facedown.

The top edge of the sheet with the logo should enter the

multipurpose feeder first.

Multipurpose feeder (duplex

printing)

Preprinted letterhead design is

placed faceup.

The top edge of the sheet with the logo should enter the

multipurpose feeder last.

Note: Check with the manufacturer or vendor to determine whether the chosen preprinted letterhead is acceptable for

laser printers.

Tips on using transparencies

Print samples on the transparencies being considered for use before buying large quantities.

When printing on transparencies:

• Feed transparencies from any tray or drawer, except the Optional 2,000‑sheet tray.

• Use transparencies designed specifically for laser printers. Check with the manufacturer or vendor to ensure

transparencies are able to withstand temperatures up to 170°C (338°F) without melting, discoloring, offsetting, or

releasing hazardous emissions.

• To prevent print quality problems, avoid getting fingerprints on the transparencies.

• Before loading transparencies, fan the stack to prevent sheets from sticking together.

• We recommend Lexmark part number 12A8240 for letter‑size transparencies and Lexmark part number 12A8241

for A4‑size transparencies.

Tips on using envelopes

Print samples on the envelopes being considered for use before buying large quantities.

When printing on envelopes:

• Use envelopes designed specifically for laser printers. Check with the manufacturer or vendor to ensure the

envelopes can withstand temperatures up to 190°C (374°F) without sealing, wrinkling, curling excessively, or

releasing hazardous emissions.

• For the best performance, use envelopes made from 90 g/m

2

(24 lb bond) paper. Use up to 105 g/m

2

(28 lb bond)

weight for envelopes as long as the cotton content is 25% or less. All‑cotton envelopes must not exceed 90 g/m

2

(24 lb bond) weight.

Printing 67