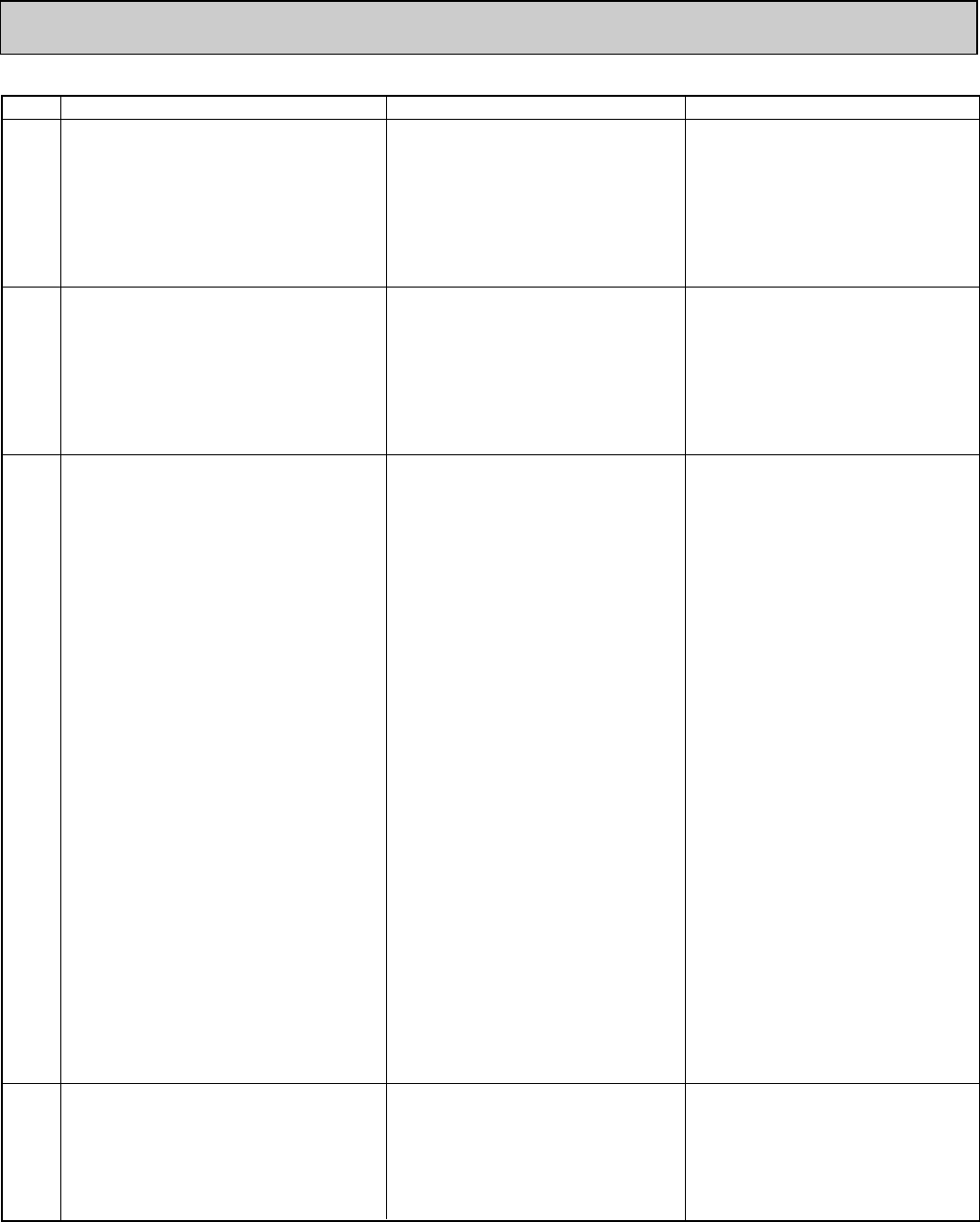

36

Display

Abnormal point and detecting method

Causes

Check points

1102

1300

1302

1500

High discharging temperature

Abnormal if discharge temperature thermistor

(TH4) exceeds 125: or 110: continuously

for 5 minutes.

Abnormal if pressure detected by high pressure

sensor and converted to saturation temperature

exceeds 40: during defrosting and discharge

temperature thermistor (TH4) exceeds 110:.

Low pressure (63L worked)

Abnormal if 63L is worked (under- 0.03MPa)

during compressor operation.

63L: Low-pressure switch

(1) High pressure (High-pressure switch

63H worked)

Abnormal if high-pressure switch 63H is

worked

( w ) during compressor operation.

w 4.15 MPa

63H: High-pressure switch

(2) High pressure

(High - pressure sensor 63HS detect)

Abnormal if high-pressure sensor detects

4.31MPa or more (or over 4.15MPa for

3 minutes) during the compressor operation.

Too low superheat due to low discharge

temperature

Abnormal if discharge super heat is

continuously detected less than or equal to

-15:

even though linear expansion valve has

minimum open pulse after compressor starts

operating for 10 minutes.

1 Over-heated compressor operation is

caused by shortage of refrigerant

2 Defective operation of stop valve

3 Defective thermistor

4 Defective outdoor controller board

5 Defective action of linear expansion

valve

1 Stop valve of outdoor unit is closed

during operation.

2 Disconnection or loose connection of

connector (63L) on outdoor controller

board

3

Disconnection or loose connection of 63L

4 Defective outdoor controller board

5 Leakage or shortage of refrigerant

6 Malfunction of linear expansion valve

1 Short cycle of indoor unit

2 Clogged filter of indoor unit

3 Decreased airflow caused by dirt of

indoor fan

4 Dirt of indoor heat exchanger

5 Locked indoor fan motor

6 Malfunction of indoor fan motor

7 Defective operation of stop valve

(Not full open)

8 Clogged or broken pipe

9 Locked outdoor fan motor

0 Malfunction of outdoor fan motor

1 Short cycle of outdoor unit

2 Dirt of outdoor heat exchanger

3 Decreased airflow caused by defective

inspection of outside temperature

thermistor (It detects lower temperature

than actual temperature.)

4 Disconnection or contact failure of

connector (63H) on outdoor controller

board

5 Disconnection or contact failure of 63H

connection

6 Defective outdoor controller board

7 Defective action of linear expansion

valve

8 Malfunction of fan driving circuit

9 Solenoid valve (SV1) performance

failure (High-pressure cannot be

controlled by SV1)

)

High-pressure sensor defective

! High-pressure sensor input circuit

defective in multi controller board.

1 Disconnection or loose connection of

discharge temperature thermistor. (TH4)

2

Defective holder of discharge temperature

thermistor.

1 Check intake super heat.

Check leakage of refrigerant.

Charge additional refrigerant.

2 Check if stop valve is full open.

34 Turn off and check if 5101 is

displayed when the power is put

again. When 5101 is displayed, refer

to “Check points” for 5101.

5 Check linear expansion valve.

1 Check stop valve.

2~4

Check the connector (63L) on outdoor

controller board.

5 Correct to proper amount of refrigerant.

6 Check linear expansion valve.

1~6 Check indoor unit and repair

defectives.

7 Check if stop valve is full open.

8 Check piping and repair defectives.

9~2 Check outdoor unit and repair

defectives.

3 Check the inspected temperature of

outside temperature thermistor on

LED display.

4~6

Check the connector (63H) on outdoor

controller board.

7 Check linear expansion valve.

8 Replace outdoor controller board.

9 Check the solenoid valve performance.

)

Check the high-pressure sensor.

!

Check the high-pressure sensor.

12 Check the installation conditions of

discharge temperature thermistor (TH4).

OC376B--2.qxp 08.1.17 1:15 PM Page 36