Part 2 Basics of the LPX-250

14

Rescanning

In general, increasing the number of scanning surfaces results in greater scanning precision with correspondingly fewer conspicuous seams.

In the example of the doll, however, only one of the five scanning surfaces can capture the voids. From the standpoint of capturing voids,

two surfaces are more effective.

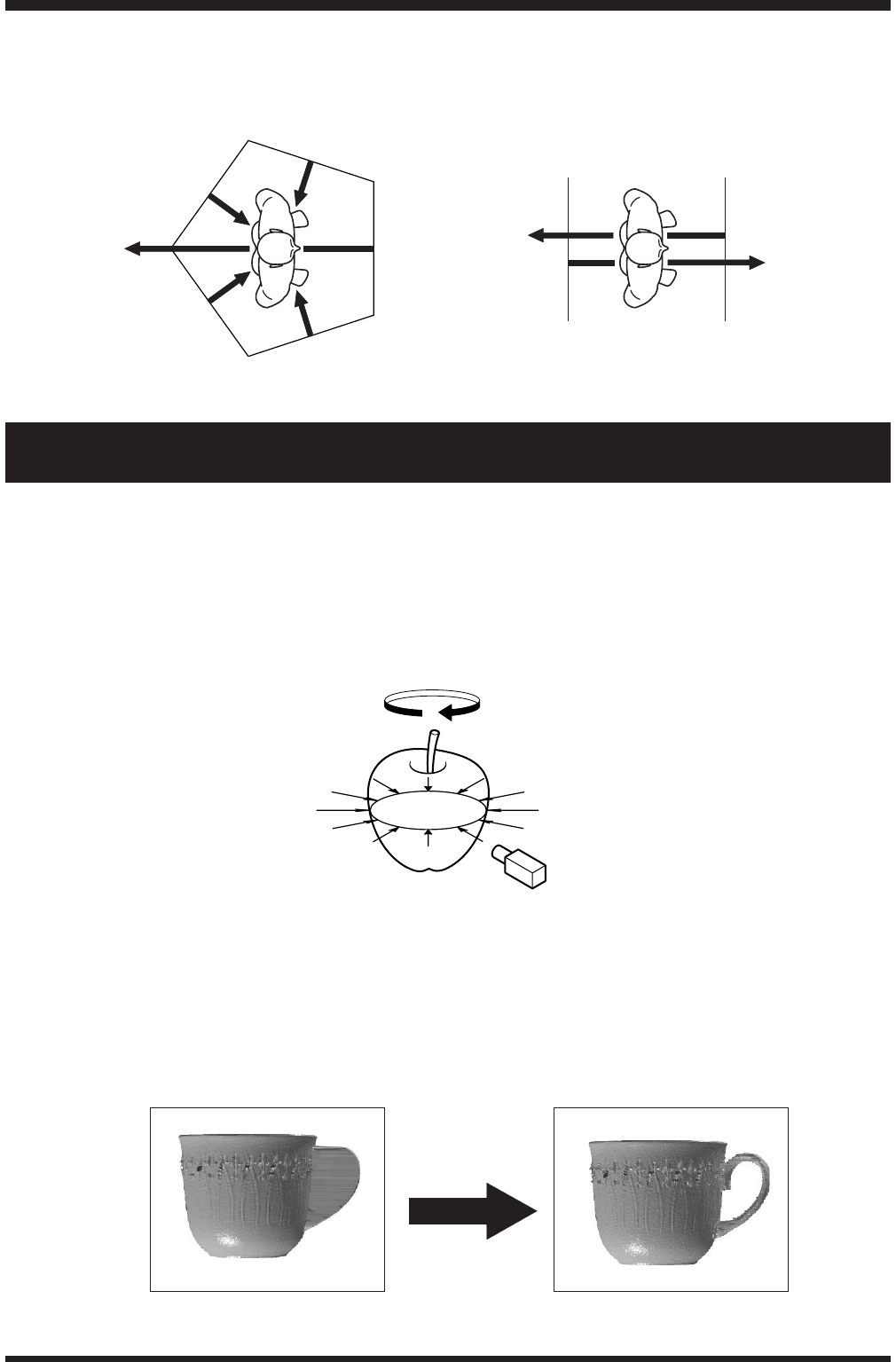

Scanning surfaces: 5 Scanning surfaces: 2

4. Rotary Scanning

Features of Rotary Scanning

This mode scans the outer perimeter of the scan object while rotating the table in one direction. This is suited to scanning objects that have

relatively little unevenness and are close in shape to a sphere or cylinder, and lets you perform smooth scanning for curved surfaces.

It is more selective of the shape of the object than plane scanning, but conversely reproduces smooth curves even at relatively coarse pitches,

and also takes less time. Capturing cavities and voids in objects is more difficult than with plane scanning.

Finishing by Rescanning

If the object is highly uneven, there may be many areas that the laser light does not reach. Rotary scanning is more likely to be affected by

this than plane scanning, and may result patches that are not scanned. With rotary scanning, you can finish such areas by rescanning.

Perform rotary scanning for the entire object, then rescan only the areas you want to finish. This enables scanning with an attractive finish

even for detailed portions while smoothly reproducing the curved features of the entire object.

Rotary scanning system

The laser beam is emitted

toward the center of the table.