Series 24-HP Instruction Manual Chapter 2 Installation

IM-24-HP 2-5

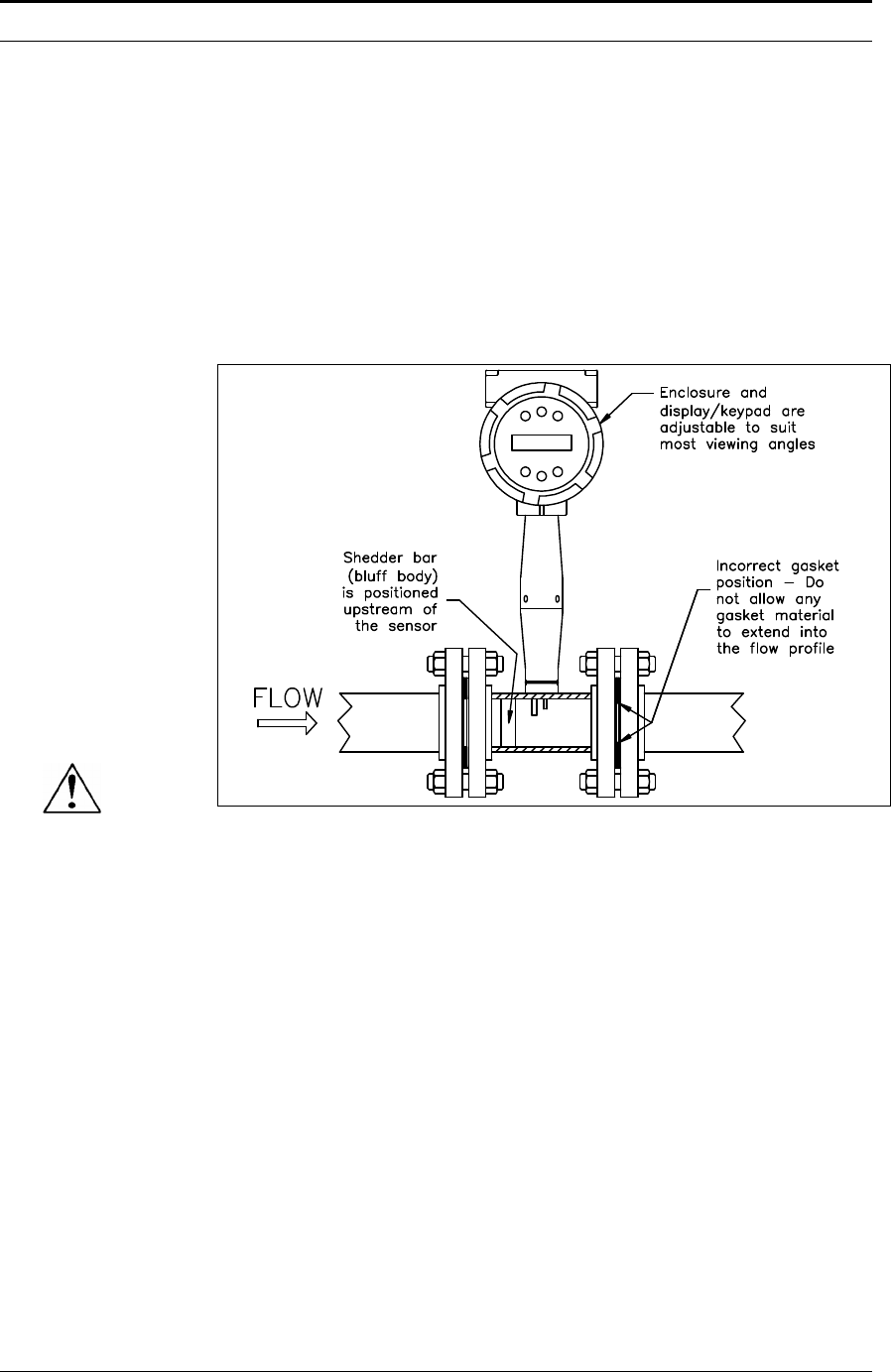

Flange-Style Flow Meter Installation

Install the flange-style meter between two conventional pipe flanges of

the same nominal size as the flow meter. If the process fluid is a liquid,

make sure the meter is located where the pipe is always full. This may re-

quire locating the meter at a low point in the piping system. Note: Vortex

flow meters are not suitable for two-phase flows (i.e., liquid and gas mix-

tures). For horizontal pipelines having a process temperature above 300°

F, mount the meter at a 45 or 90-degree angle to avoid overheating the

electronics enclosure. To adjust the viewing angle of the enclosure or dis-

play/keypad, see page 2-17.

Figure 2-4. Flange-Style Flow Meter Installation

When installing the meter make sure the flange marked “inlet” is positioned

upstream of the outlet flange, facing the flow. This ensures that the sensor

head is positioned downstream of the vortex shedder bar and is correctly

aligned to the flow. Installing the meter opposite this direction will result in

completely inaccurate flow measurement. To install the meter:

1. Turn off the flow of process gas, liquid or steam. Verify that the line

is not pressurized. Confirm that the installation site meets the re-

quired minimum upstream and downstream pipe diameters.

2. Seat the meter level and square on the mating connections with the flange

marked “inlet” facing the flow. Position a gasket in place for each side.

Make sure both gaskets are smooth and even with no gasket material ex-

tending into the flow profile. Obstructions in the pipeline will disturb the

flow and cause inaccurate measurements.

3. Install bolts in both process connections. Tighten the nuts in the se-

quence shown in Figure 2-2. Check for leaks after tightening the flange

bolts.

Caution!

When using toxic or corro-

sive gases, purge the line

with inert gas for a mini-

mum of four hours at full

gas flow before installing

the flow meter.