Chapter 2 Installation Series 24-HP Instruction Manual

2-14 IM-24-HP

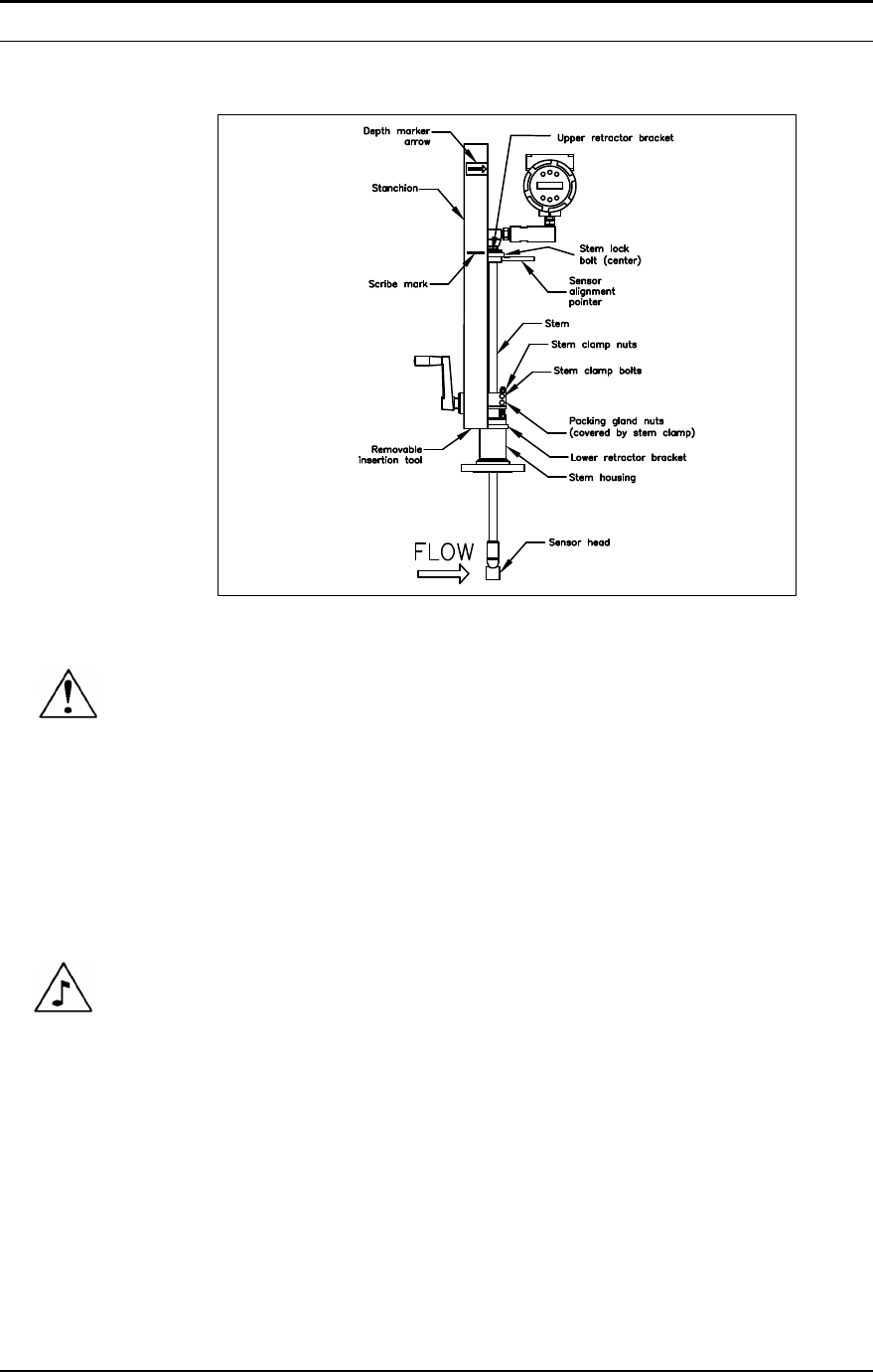

Insertion Procedure for Flow Meters with Removable Insertion Tool

Figure 2-10. Flow Meter with Removable Insertion Tool

1. Calculate the required sensor probe insertion length. Measure from

the depth marker arrow down the stanchion and scribe a mark at the

calculated insertion depth.

2. Fully retract the flow meter until the sensor head is touching the bot-

tom of the stem housing. Attach the meter assembly to the two inch

full-port isolation valve, if used. Use Teflon tape or pipe sealant to

improve seal and prevent seizing on NPT style.

3. Remove the two top stem clamp nuts and loosen two stem clamp

bolts. Slide the stem clamp away to expose the packing gland nuts.

4. Loosen the two packing gland nuts. Loosen the stem lock bolt adja-

cent to the sensor alignment pointer. Align the sensor head using the

sensor alignment pointer. Adjust the alignment pointer parallel to the

pipe and pointing downstream. Tighten the stem lock bolt to secure

the sensor position.

5. Slowly open the isolation valve to the full open position. If necessary,

slightly tighten the two packing gland nuts to reduce the leakage

around the stem.

6. Turn the insertion tool handle clockwise to insert the stem into the

pipe. Continue until the top of the upper retractor bracket lines up

with the insertion length mark scribed on the stanchion. Do not force

the stem into the pipe.

Caution!

The sensor alignment

pointer must point

downstream, in the

direction of flow.

Note

If line pressure is above

500 psig, it could require

up to 25 ft lb of torque to

insert the flow meter.

Do not confuse this with

possible interference

in the pipe.