Initial Inspection

The Symmetra

TM

Power Array system is shipped on pallets.

The system frame is bolted to one pallet, and the modules are

boxed, and stacked on one or two additional pallets.

Check For Damage

1. Inspect the Packaging - for damage or signs of mishan-

dling before moving the pallets. If damage is detected, note it

on the Bill of Lading.

2. If Any Damage Is Detected - file a damage claim with the

shipping agency within 24 hours. Contact APC Customer

Service at 1-800-800-APCC to inform them of the damage

claim, and the condition of the equipment.

3. System Administrator- make sure the system administra-

tor participates in the initial inspection.

Table 3-1 Dimensions and Weights

Handling Considerations

1. The Frame Pallet - See Table 3-1 for frame pallet weight and

dimensions. Before removing shipping materials, the frame

and pallet should be positioned as close as possible to the

installation site. The frame is bolted to a specially designed

pallet, and is removed from the pallet using a ramp that is

included. Use a pallet jack to position the frame pallet.

Note: Do not attempt to move the frame with a hand dolley.

2. The Modules Pallet - If possible, it is recommended that the

module pallet(s) be positioned as close as possible to the final

installation site with the pallet jack. If this is not possible,

remove the outer packaging materials from the module car-

tons, and carry each individual, boxed module to the installa-

tion site. See Table 3-1 for module weights.

Chapter 3 - Unpacking and Installing Frame

3-1

Tools Required for Setup

The following tools are required to move the pallets into place,

remove packaging materials, install the ramp on the frame

pallet, and to remove the frame from the pallet.

1. Large Philips screwdriver

2. Adjustable, open-end wrench

3. Heavy duty shears

4. Sharp utility knife

5. Pallet jack

Storage of Battery and Power

Modules

The modules must be temporarily set aside, while the frame is

installed and wired. To preserve battery life, always store bat-

tery modules in a cool, dry place.

Moving the Frame

1. Plan the Route - Make sure all passages are large enough to

accomodate the frame, and the pallet jack. Check to see that

the floor has sufficient strength. See Table 3-1 for weights and

dimensions. Check doorways, elevators, ramps, etc, to insure

there are no non-negotiable corners, step-ups, or offsets. Se-

lect a route that provides the smoothest possible floor surface.

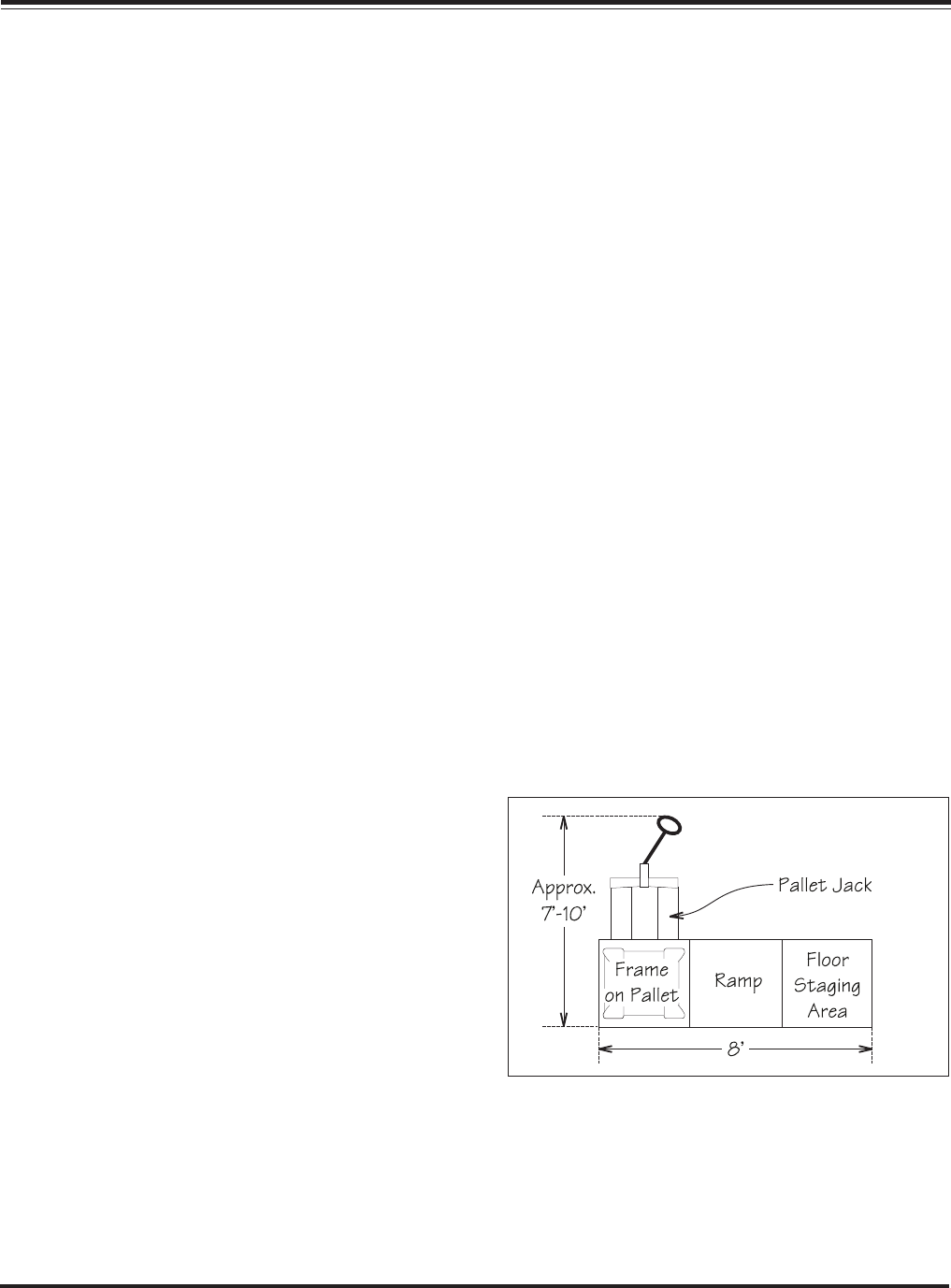

2. Staging Area - A smooth, level floor surface is required to

position the frame pallet, remove the packaging materials, in-

stall the ramp, and for two people to carefully roll the frame

down the ramp, and onto the floor. See Figure 3-1 below for

staging area dimensions.

Fig 3-1 Staging Area

3. Using a Pallet Jack - Carefully move the frame to the stag-

ing area.