System Overview

42

5.1.13 System Safety

Every composite flywheel is inspected, spin balanced and tested to 110% over-speed in accordance

with NEMA guidelines. A patented dual-wall safety system ensures that in the unlikely event a fly-

wheel were to separate during operation, the inner housing would retain the carbon fiber. As the car-

bon fiber separates, it will expand and transfer its torque to the inner housing. The inner housing is

then allowed to rotate inside the outer housing. The cooling fluid in the outer housing, which sur-

rounds the inner housing acts as a dynamic brake. The stored energy is released in a controlled man-

ner as the flywheel / inner housing comes to a rest. The outer housing holds the entire safety system

and acts as a reservoir for the cooling fluid

The Liebert FS has been previously tested under the following fault conditions with no adverse safety

effects:

• Motor-generator AC short circuit

• DC short circuit

• Power Conversion Module failure

• Magnetic Levitation System failure

• Composite rotor failure

• Motor Rotor Failure

• Loss of Vacuum

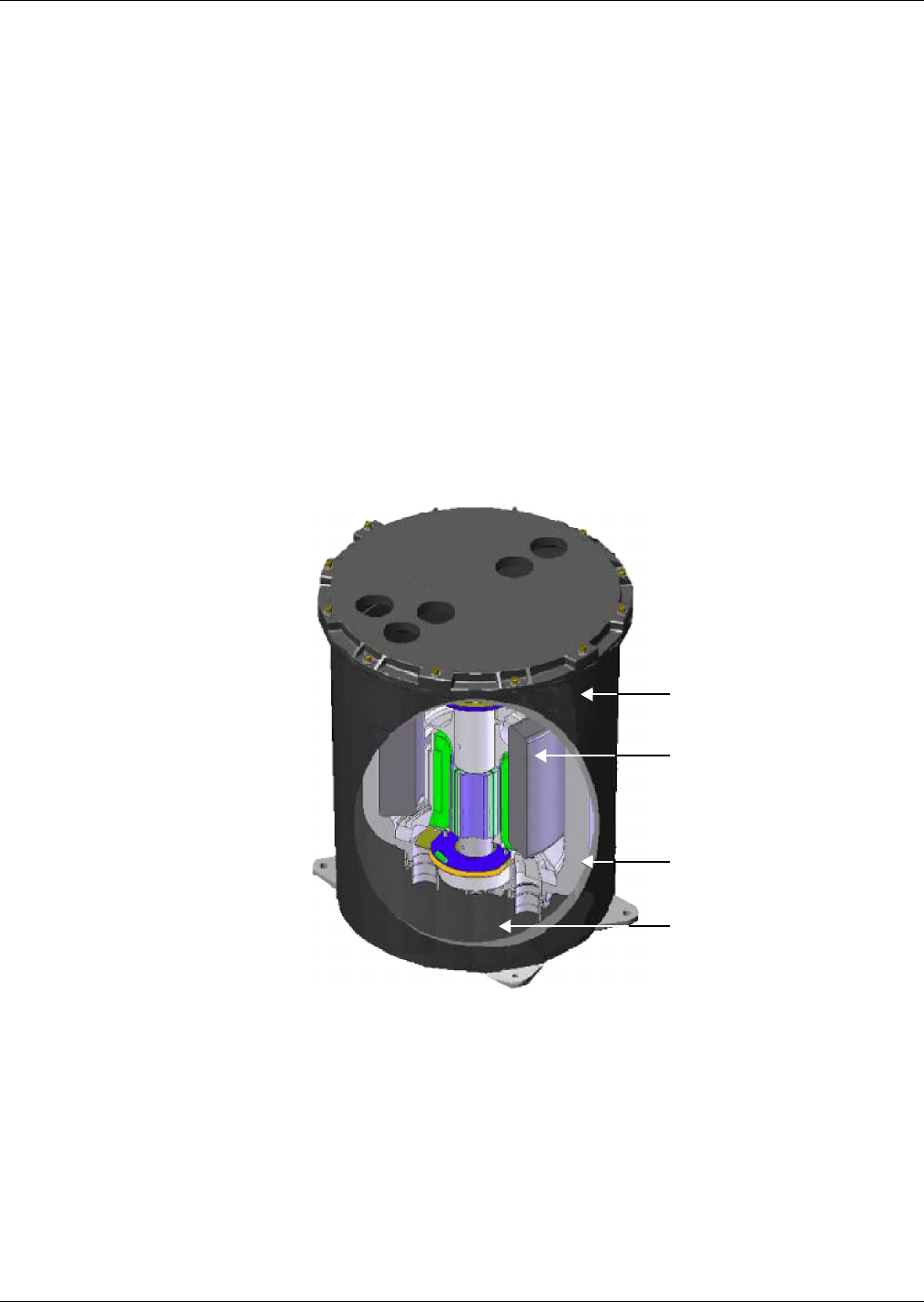

Figure 43 Cutaway flywheel module

5.1.14 Cabinet

The Liebert FS is a compact design housed in a free-standing cabinet with a NEMA 1 construction

rating or IEC equivalent. No space is required between the back or sides of the cabinet and any walls.

The front clearance of 36" per the National Electrical Code is required. The Liebert FS accommodates

top (standard) and side entry cables. The Liebert FS can be rolled into place and go through standard

doors.

Outer Housing

Rotating Group

Inner Housing

Coolant