2-267

2 Instructions

CP1E CPU Unit Instructions Reference Manual(W483)

Data Control Instructions

2

PIDAT

Sample program

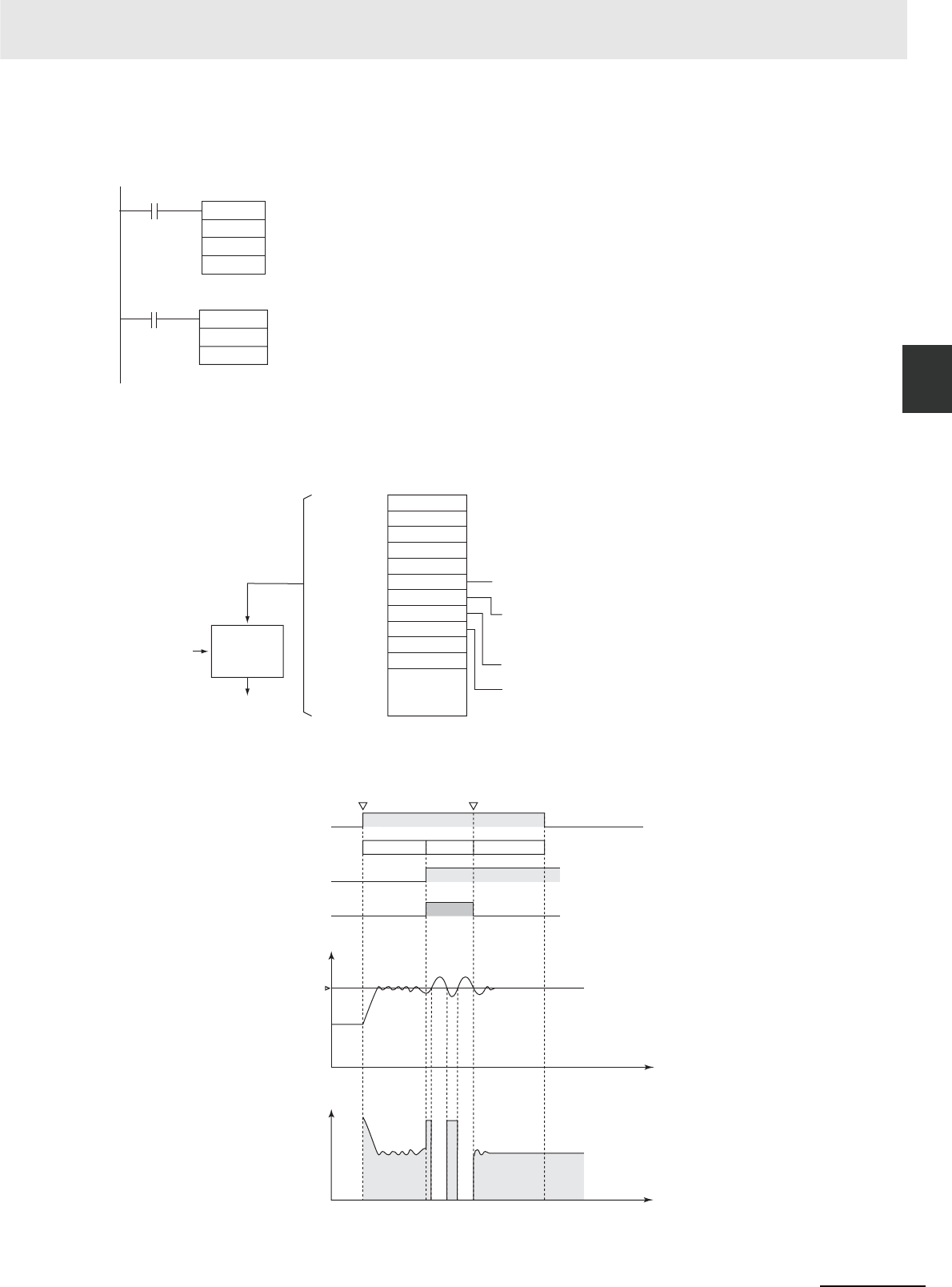

Interrupting PID Control to Perform Autotuning

• At the rising edge of CIO 0.00 (OFF to ON), the work area in D211 to

D240 is initialized according to the parameters (shown below) set in

D200 to D208. After the work area has been initialized, PID control is

executed and the manipulated variable is output to CIO 20.

• While CIO 0.00 is ON, PID control is executed at the sampling period

intervals according to the parameters set in D200 to D210. The manip-

ulated variable is output to CIO 20.

• The PID constants used in PID calculations will not be changed even if

the proportional band (P), integral constant (Tik), or derivative con-

stant is changed after CIO 0.00 turns ON.

• At the rising edge of W 0.0 (OFF to ON), SETB(532) turns ON bit 15 of

D209 (C+9) and starts autotuning. When autotuning is completed, the

calculated P, I, and D constants are written to C+1, C+2, and C+3. PID

control is then restarted with the new PID constants.

PIDAT

10

D200

20

0.00

S

C

D

W0.0

SETB

D209

#000F

C:D200

C+1:D201

C+2:D202

C+3:D203

C+4:D204

C+5:D205

C+6:D206

C+7:D207

C+8:D208

C+9:D209

C+10:D210

C+11:D211

C+40:D240

Set value: 300

Proportional band: 10.0%

Integral time: 120.0 s

Derivative time: 40.0 s

Sampling period: 0.5 s

PID

calculation

Parameters

PV:

CIO 10

MV output: CIO 20

Reverse operation (bit 00: 0), PID constant change enable setting = OFF

(bit 01: 0), set value = manipulated variable output 50% (bit 03: 1), 2-PID

parameter = 0.65 (bits 04 to 15: 000 hex)

AT Command Bit OFF (bit 15: 0),

AT Calculation Gain = 1.00 (bits 00 to 11: 000 hex)

CIO 0.00

PID control starts

Calculated PID

constants are set.

W0.00

Bit 15 of D209

PV

SV

Time

MV

Time

to

012C

0064

04B0

0190

0032

0000

0494

0000

0000

0000

0000

Work area

Manipulated variable output range: 12 bits (bits 00 to 03: 4 hex),

Integral/derivative constant: time designation (bits 04 to 07: 9 hex)

Input range: 12 bits (bits 08 to 11: 4 hex),

Manipulated variable output limit control disabled (bit 12: 0)

Limit-cycle Hysteresis = 0.20%

PID starting integral manipulated variable designation = start from same

integral manipulated value as manipulated variable output designation

(bit 14: 0 and bit 13: 0)

PID control PID control

AT executing