(2) Manual paper feed tray operation

Select the manual paper feed tray and press the START button, and

the manual paper feed roller will be turned on to bring the paper feed

roller in contact with paper and lift the shutter simultaneously.

The drive power of the main motor is transmitted through the manual

paper feed roller clutch to the manual paper feed roller, rotating the

manual paper feed roller and feeding paper.

(3) Resist roller

In order to make synchronization between the paper lead edge fed

from the paper feed port and the image lead edge, the roller is kept

stationary for a certain time after the paper reaches at the roller to

warp the paper a little.

When the paper is warped to a certain level, the resist roller solenoid

is turned on to release the resist roller clutch.

The drive power of the main motor is transmitted through the resist

roller clutch to the resist roller, rotating the resist roller and feeding

paper.

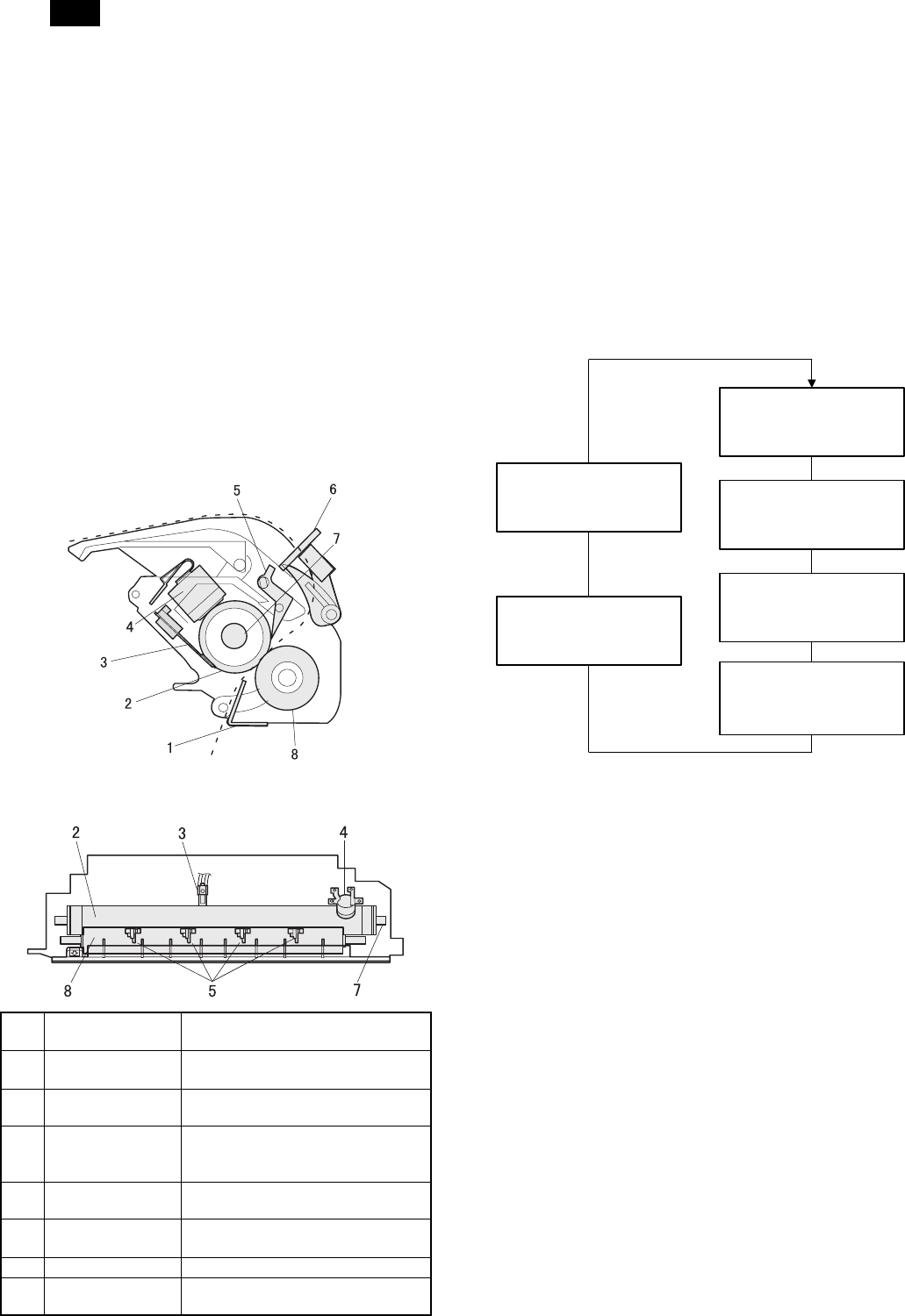

6. Fusing section

A. Basic composition

(Top view)

1 Before-fusing

paper guide

Guides the paper transported from

the process section to the fusing unit.

2 Upper heat roller Applies heat and pressure to the

paper to fuse.

3 Thermistor Detects the surface temperature of

the upper heat roller.

4 Thermostat Stops power supply to the heat roller

in case of an abnormally high

temperature of the heat roller.

5 Separation pawl Separates the print paper from the

upper heat roller.

6 POD1 Detects that the paper has been

transported from the fusing section.

7 Heater lamp Heats the heat roller.

8 Lower heat roller Applies a pressure to the paper

together with the upper heat roller.

B. Heat roller

A pressure roller is used for the heat roller and a silicone rubber roller

is used for the lower heat roller for better toner fusing performance

and paper separation.

C. Separator pawl

Four separator pawls are used on the upper heat roller. The

separator pawls are teflon coated to reduce friction with the roller and

prevent a smear on the paper caused by the separator pawl.

D. Thermal control

1) The heater lamp, thermistor, main PWB, DC power supply PWB,

and triac within the power supply unit are used to control the

temperature in the fuser unit.To prevent against abnormally high

temperature in the fuser unit, a thermostat is used for safety pur-

poses.

2) The surface temperature of the upper heat roller is set to 180˚C ~

195˚C. The surface temperature during the power save mode is

set to 100˚C.

3) The self-check function comes active when one of the following

malfunctions occurs, and an "H" is displayed on the copy quantity

display.

Fusing temperature error value

H4 (Low temperature error)

• During machine operation

The case where the fusing temperature (thermistor output

value) does not reach 155˚C within 55 sec from lighting of the

heater lamp. (If the toner motor rotates for 10 sec or more

continuously when starting the machine, the case where the

fusing temperature does not reach 155˚C within 60 sec.)

• During printing

When the fusing temperature (thermistor output value) falls

below 145˚C.

H3 (High temperature error)

Fusing temperature (thermistor output value) of about 220 to

240˚C (varies depending on the resistance.)

E. Fusing resistor

(1) Fusing resistor

Since the upper heat roller is conductive when copy paper is highly

moistured and the distance between the transfer unit and the fusing

unit is short, the transfer current leaks through the copy paper, the

upper heat roller and the discharging brush.

To prevent against this, a resistor of 150MOhm is provided between

the frame and the discharge brush to minimize leak current and

improve transfer efficiency.

Safety device

(thermal breaker, thermal

fuse)

Triac (in the

power supply unit)

Heated by the

heater lamp.

(950W )

The surface temperature

of the upper heat roller

is sensed by the thermistor.

Level of the thermistor is

controlled by the main PWB.

With the signal from the

main PWB, the triac is

controlled on and off.

(power supply PWB )

AR-160/161 FM/E [6] OPERATIONAL DESCRIPTIONS 11/27/1998

AR-161

6 – 7