Watlow EZ-ZONE

®

PM Integrated Controller • 62 • Chapter 9 Features

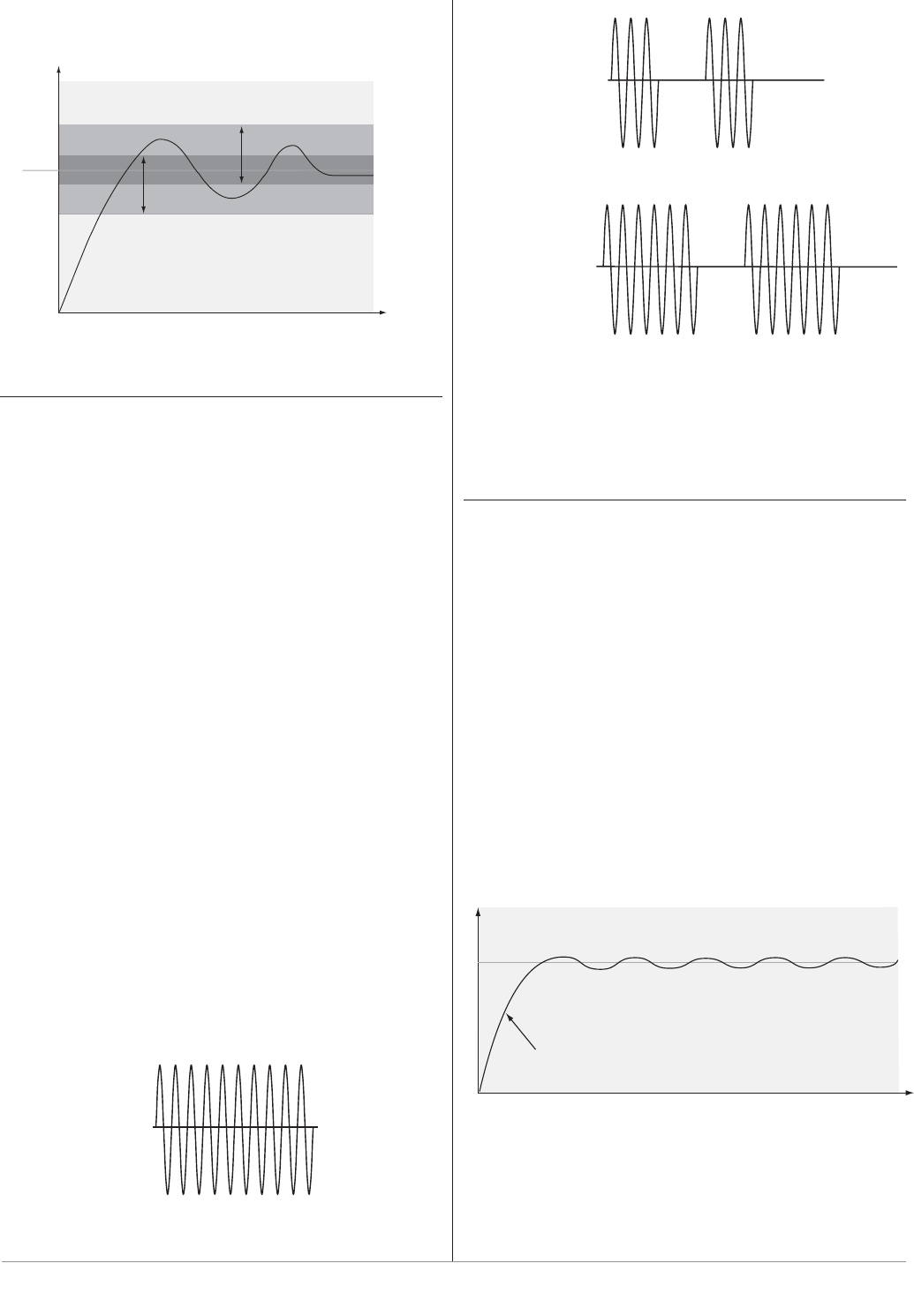

When the dead band value is a negative val-

ue, both heating and cooling outputs are active when

the temperature is near the set point.

Time

Temperature

Negative Dead Band

Set Point

Heat Output Active

Cool Output Active

Adjust the dead band with Dead Band [``db]

(Operations Page, Loop Menu).

Variable Time Base

Variable time base is the preferred method for con-

trolling a resistive load, providing a very short time

base for longer heater life. Unlike phase-angle firing,

variable-time-base switching does not limit the cur-

rent and voltage applied to the heater.

With variable time base outputs, the PID algo-

rithm calculates an output between 0 and 100%, but

the output is distributed in groupings of three ac

line cycles. For each group of three ac line cycles, the

controller decides whether the power should be on or

off. There is no fixed cycle time since the decision is

made for each group of cycles. When used in conjunc-

tion with a zero cross (burst fire) device, such as a

solid-state power controller, switching is done only at

the zero cross of the ac line, which helps reduce elec-

trical noise (RFI).

Variable time base should be used with solid-state

power controllers, such as a solid-state relay (SSR)

or silicon controlled rectifier (SCR) power controller.

Do not use a variable time base output for control-

ling electromechanical relays, mercury displacement

relays, inductive loads or heaters with unusual resis-

tance characteristics.

The combination of variable time base output and

a solid-state relay can inexpensively approach the ef-

fect of analog, phase-angle fired control.

Select the AC Line Frequency [AC;LF] (Setup Page,

Global Menu), 50 or 60 Hz.

100 percent output

10 ON, 0 OFF

50 percent output

3 ON, 3 OFF

66 percent output

6 ON, 3 OFF

Note:

When output 1 is a universal process output, output 2 cannot

use variable time base, fixed time base only.

When output 3 is configured as a universal process, output 4

cannot use variable time base, fixed time base only.

Single Set Point Ramping

Ramping protects materials and systems that can-

not tolerate rapid temperature changes. The value of

the ramp rate is the maximum degrees per minute or

hour that the system temperature can change.

Select Ramp Action [``rP] (Setup Page, Loop

Menu):

[`oFF] ramping not active.

[`Str] ramp at startup.

[StPt] ramp at a set point change.

[both] ramp at startup or when the set point

changes.

Select whether the rate is in degrees per minute

or degrees per hour with Ramp Scale [`r;SC]. Set

the ramping rate with Ramp Rate [`r;rt] (Setup

Page, Loop Menu).

Set Point

Time

Temperature

Temperature reaches Set Point quickly