ADVANCED MICRO SYSTEMS, INC. HARDWARE

12

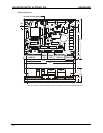

Typical Wiring Diagrams for Step Motors

Fig. A: Series winding for higher torque and lower current. The inductance is 4 times that of the parallel

mode, reducing the maximum obtainable speed.

Fig. B: Parallel winding for better high-speed performance but requires higher drive current. A 4-wire motor

is the same as an 8-wire motor, but it is connected (in either parallel or series) internally. Some motors can be

rewired at the factory.

Fig. C: A 6 wire motor is a variation of the 8 wire series configuration, where the “center taps” are available.

The 6-wire motor can be used in series mode but cannot be connected in parallel. A compromised 50%

copper connection can be used, producing higher speed with reduction of torque.

Note: NEVER connect or disconnect the motor when the power is “ON”. Wait at least two minutes after

turning off the power before connecting or disconnecting the motor. This will allow proper dissipation of

voltage from the unit. Failure to do so may cause damage and void the warranty.

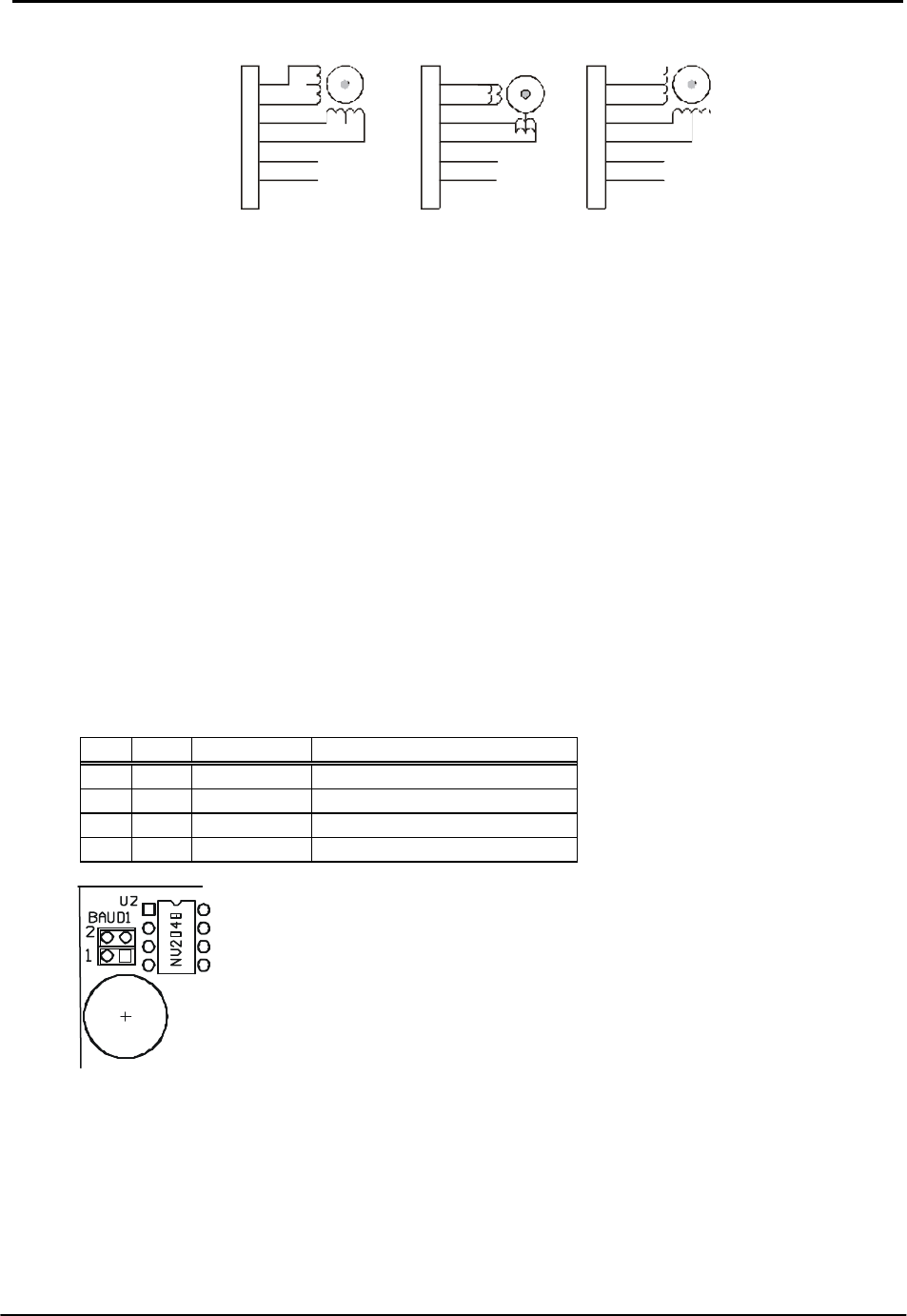

Baud Rate Jumpers (B1, B2)

Jumpers B1and B2 determine the baud rate. Standard UART properties are no parity, 8 data bits, 1 stop bit.

B1 B2 Baud Rate Comment

N N 9600 Factory setting N, 8, 1

Y N 460k Requires SIN-10 serial adapter

N Y 38.6k

Y Y 19.2k

+ Power

- GND

High Torque

+ Power

- GND

High Speed

Bipolar 50% Copper

Bipolar Series

FIG A

FIG C

+ Power

- GND

High Speed

PH-0

PH-1

PH-2

PH-3

VMM

GND

Bipolar Parallel

FIG B

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1