62

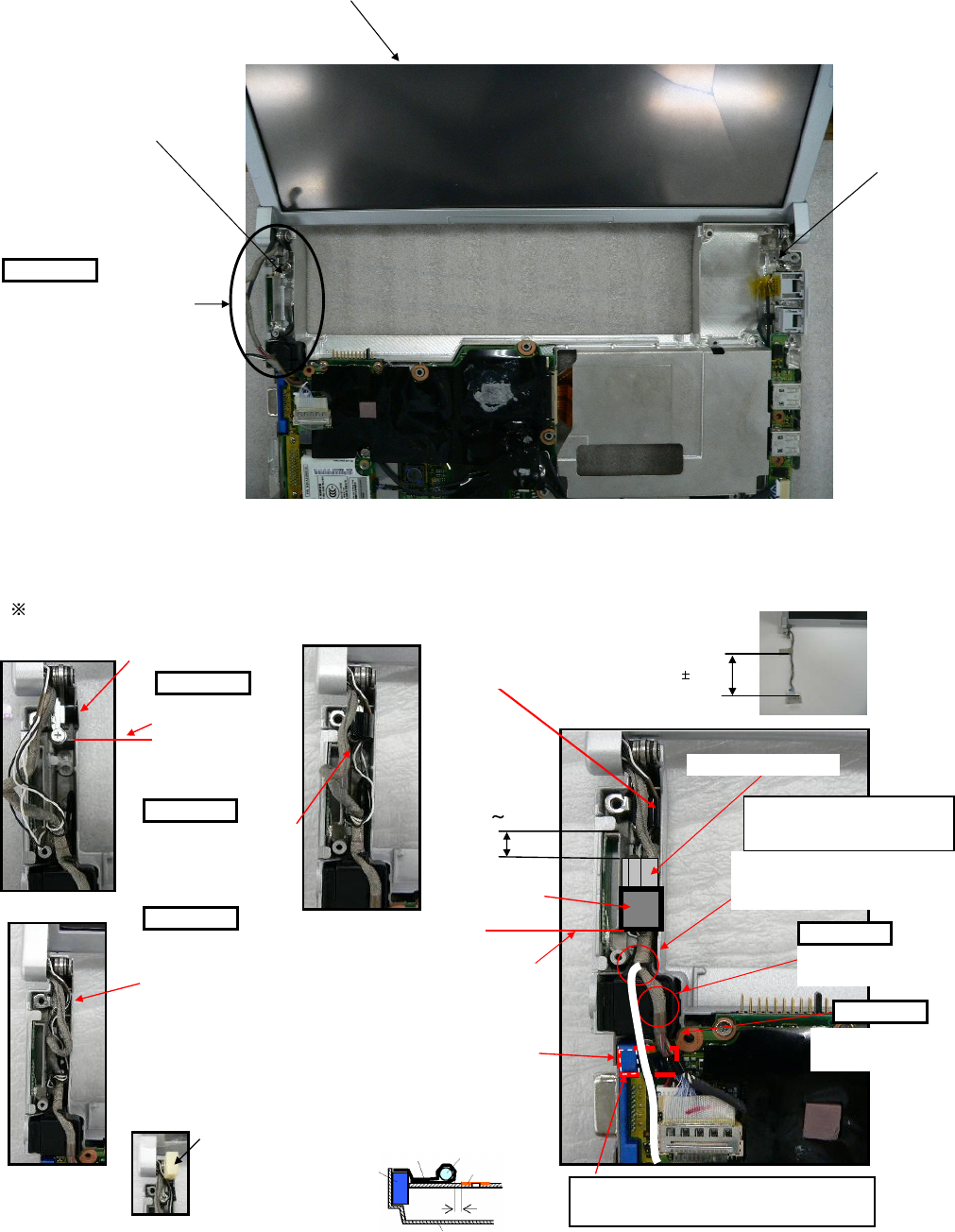

9.3.6. Assembly knowhow of the Body

9.3.6.1. Setting LCD

LCD UNIT

SCREW(a)

DXQT26+D5FNL

SCREW(b)

DXQT26+D5FNL

Conductive Cloth is wrapped.

Safety work

Bottom Case

MAIN PWB

Safety work

Safety work

Safety work

Safety work

Safety work

The final state

Work is executed in order of (1) (2) (3) (4).

60 3mm

Conductive Cloth

TP Cable Fix Sheet

TP Cable Fix Sheet

Affixes to the wall

at bottom by the

rib match.

The seat is rolled to

cover the cable, and

puts on the hinge wall.

A two sided tape is pasted

to the wall according to the

edge of the wall.

After the line is processed,

pushes with the cushion.

Sheet does not run

aground in Screw hole land.

TP Cable

Fix Cushion

Running aground

prevention treatment

device

The cable is passed

between the screw

head and the Bottom Wall.

Do not run aground on the

friction board of the hinge.

(Use the treatment device)

The LCD cable is passed on

the seat at the left of the TP

cable.

4 8mm

(2) Cable processing

to ditch

The cable passes on the DC Jack Holder,

fixes on the side of the LCD signal line.

(3) Cable processing

to DC Jack Holder

(Round parts is pressurized)

Line processing sheet

Cable

VGA connector

Machine screw hole land

The space is secured.

(1) Affixes in the connector

molding part.

(4) The cable processed under

the hanging part on the edge.

(floatage prevention)

rolls in the LCD cable, and

about 8mm at the edge <bot-

tom case sidewall> is affixed.

9.3.6.2. Line processing LCD Cable (bottom case side)