21

PRE-COATING BOARDS

This process is used to coat substrates with a self-

adhesive coating onto which images can be mounted.

Images can then be mounted on the substrate. This

same process is used to create a Sled (refer to Glossary).

LAMINATOR SETTINGS:

FRONT CONTROL PANEL

Main Roller Pressure: 35-40 PSI

Motor Speed Setting: 3-5 FPM (1-1.5 MPM)

WEBBING SETTINGS

Web Tension Top: Medium

Web Tension Bottom: NA

Shim Wheel Setting: Substrate determined

IMPORTANT! Ensure that the Shim Wheel

settings of the rollers correspond to the board

thickness.

WEBBING PROCEDURE

• Load the roll of pressure sensitive adhesive onto the

top unwind shaft of the laminator with the exposed

adhesive facing you.

• Use a leader-board of the same thickness as the

boards to be coated.

• Pull the adhesive down from the top unwind shaft

and place evenly across the face of both rollers.

• Press the foot switch and using the leader -board,

push the adhesive into the roller nip

• Release the foot switch when the rear edge of the

leader-board is almost leaving the roller nip.

• Position the board to be coated into the nip, behind

the leader board and choose a speed setting.

• Press the motor switch ON or use the footswitch to

process the board.

NOTE: When coating boards, ensure that the next

board to be coated follows the previous board

without any gaps.

NOTE: Follow the last board being coated with

another leader-board again to allow the final board

to clear the laminating rollers and then stop the

motor and raise the top roller.

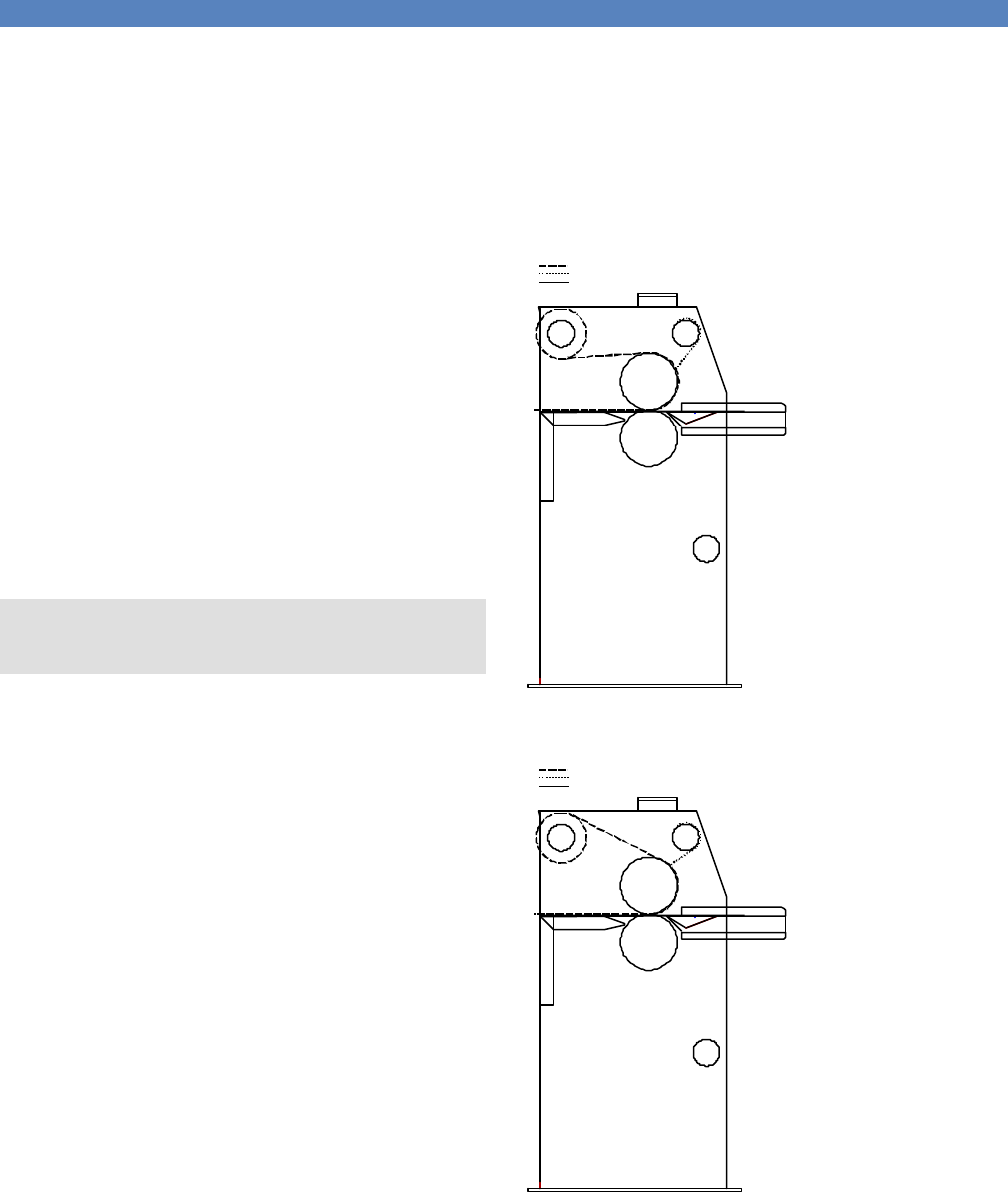

Unwind

Shaft

TOP

ROLLER

BOTTOM

ROLLER

Wind-Up

Idler

Pressure-sensitive mounting adhesive

Sled

Unwind

Shaft

Release Liner

Figure 14. Pre-Coating Boards for North America

Unwind

Shaft

TOP

ROLLER

BOTTOM

ROLLER

Wind-Up

Idler

Pressure-sensitive mounting adhesive

Sled

Unwind

Shaft

Release Liner

Figure 15. Pre-Coating Boards for Europe & Asia