22

APPLYING AN OVER-LAMINATE

An Over-laminate with a release liner can be applied to

your mounted prints, photographs or images on

photographic papers. A Sled (refer to Glossary) is

needed to support non-mounted prints during the

laminating process. Non-mounted prints are placed face

up on the sled and over-laminated as the sled passes

through the rollers. Follow the same basic procedures

for over-laminating mounted prints, eliminating the sled

use.

For double-sided laminating (encapsulating), over-

laminate and trim the first side and then repeat the

process for the second side.

MEDIA: INK JET, ELECTROSTATIC, AND

PHOTOGRAPHIC

FILMS:

Top Unwind: Pressure-sensitive Adhesive

Bottom Unwind: NA

LAMINATOR SETTINGS:

FRONT CONTROL PANEL

Main Roller Pressure: 35-40 PSI

Motor Speed Setting: 3-5 FPM (1-1.5 MPM)

WEBBING SETTINGS

Web Tension Top: Light

Web Tension Bottom: NA

Shim Wheel Setting: Substrate determined

IMPORTANT! Ensure that the Shim Wheel

settings of the rollers correspond to the board /

sled thickness.

NOTE! Web the top laminate following the basic

procedures for webbing films with a release liner

for your specific location.

NOTE: When over-laminating mounted prints, or

non-mounted prints on sleds, ensure that the board

follows directly behind the leader board without

any gaps.

NOTE: Follow the last board being processed with

another leader-board again to allow the final board

to clear the laminating rollers and then stop the

motor and raise the top roller.

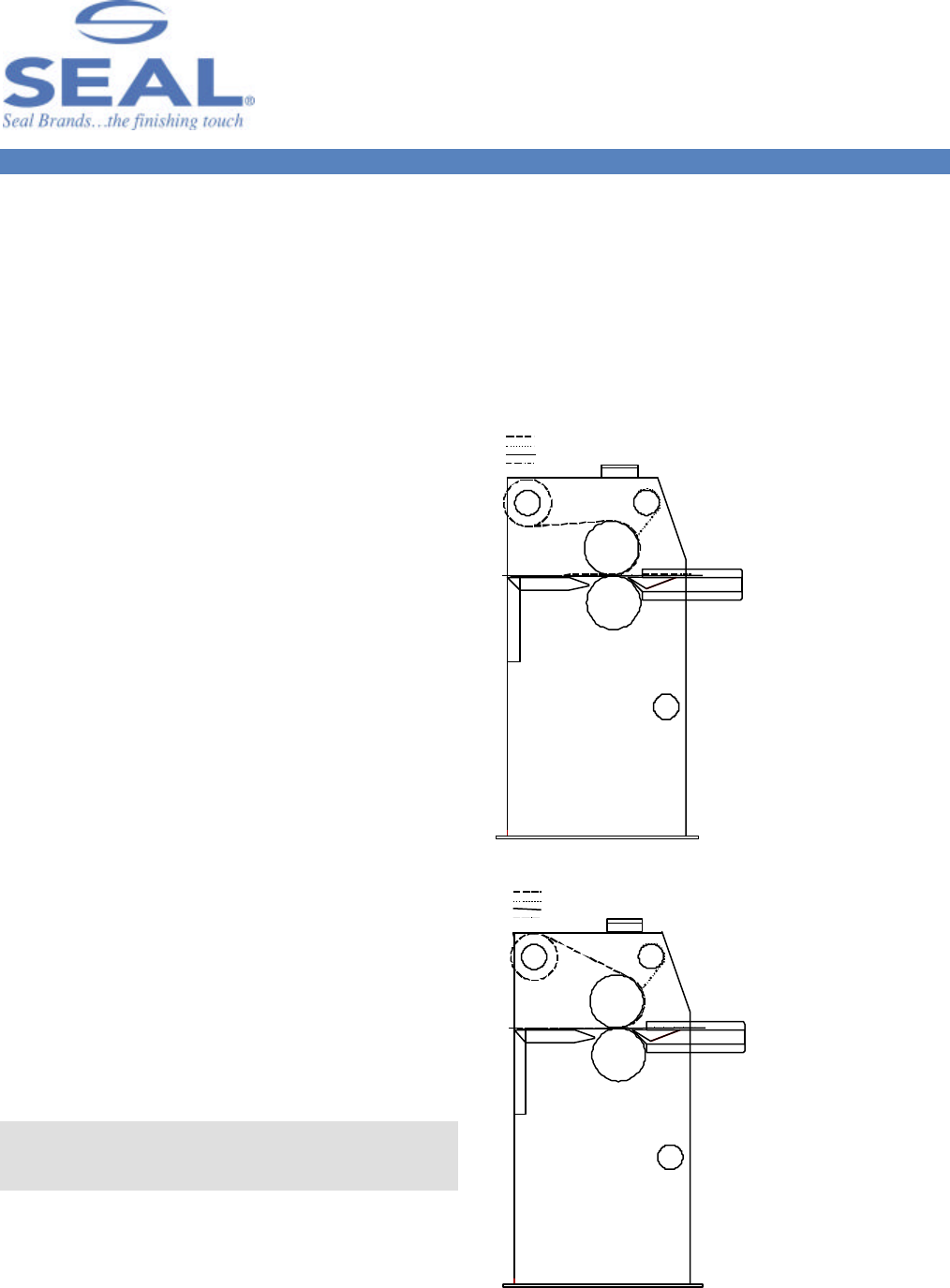

Figure 16. Webbing for

Applying an Over-laminate

for North America

Figure 17. Webbing for

Applying an Over-laminate

for Europe & Asia

Unwind

Shaft

TOP

ROLLER

BOTTOM

ROLLER

Wind-Up

Idler

Sled

Unwind

Shaft

Image

Pressure-Sensitive Over-Laminate

Release Liner

Unwind

Shaft

TOP

ROLLER

BOTTOM

ROLLER

Wind-Up

Idler

Sled

Unwind

Shaft

Image

Pressure-Sensitive Over-Laminate

Release Liner