August 2006 PROCESS CONTROL

6-83

Detailed

Descriptions

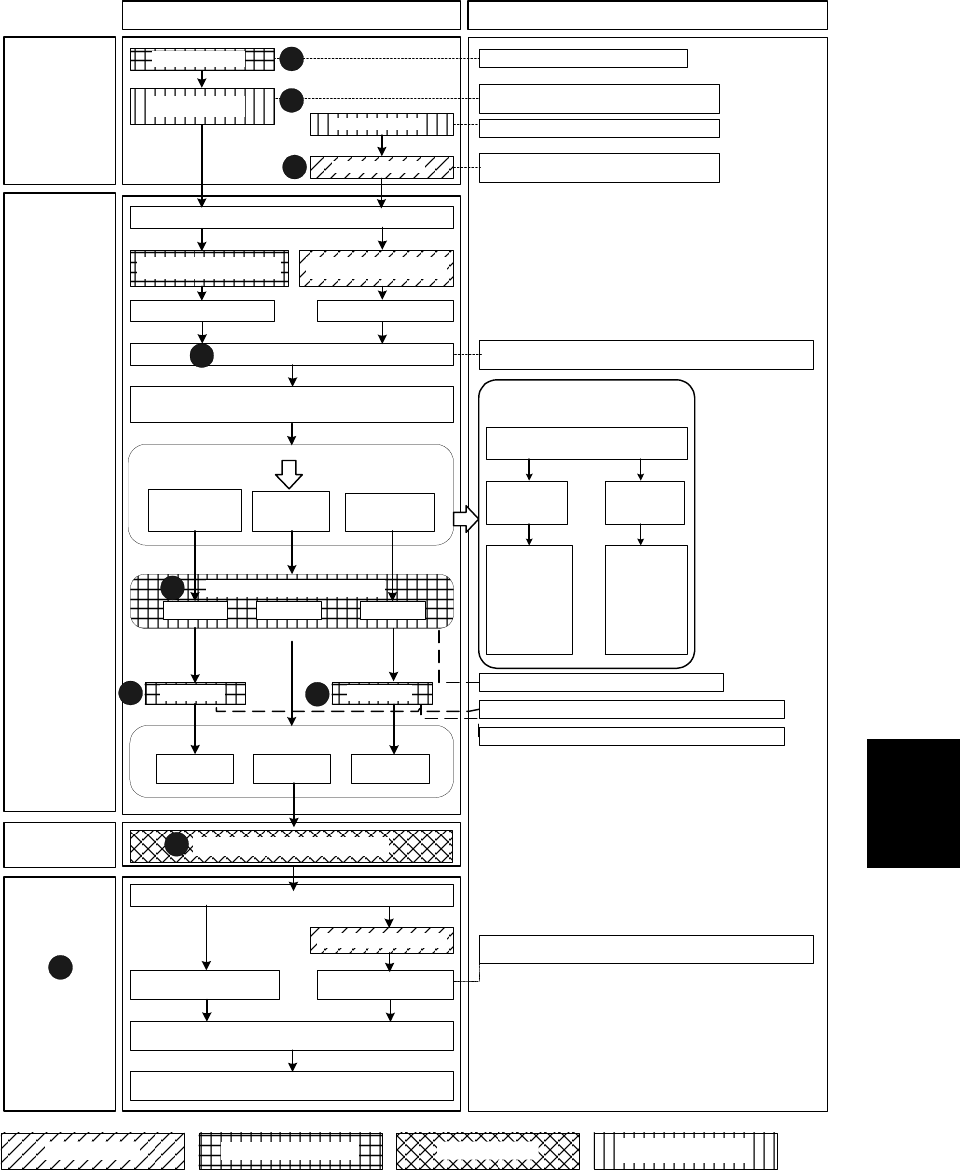

What is Done During Potential Control?

Pre-Processing

Sensor Check

Potential Control

(Toner Application

Control)

TD Sensor Output

Calibration

Process Control

Gamma Correction

Adjust Vsg

Create 10-Gradation Pattern Potential Sensor Pattern

ID Sensor Reads Developed

Pattern on the ITB

Calculate Potential Calculate Toner Amount

Calculate Development Gamma

Calculate Development Potential to Acquire

Targeted Maximum Amount of Toner

Refer to Pointer Table

Get Target Vd

for Charge Roller

Get Target Vpl

for Laser Power

Get Target Vb

for Dev. Bias

Adjust Vd

Adjust Vpl

Determine Settings to Create

Image

Drum Charge

DC

Development

Bias DC

LD Power

(PM)

Create 16-Gradation Pattern

ID Sensor Reads Pattern

LD Exposure Value Curve

Plotted

Change Amount of Toner

Calculate LD Gamma Curve

Update Process Control Gamma Table

Potential Control Process Flow

Relating SC Codes

*Adjusted for each color (Y, M, C, K)

SC436 to 439: Potential Sensor Error :vd

SC316 to 319: AC Bias Charge Adjustment Error

SC497: Temperature and Humidity Sensor Error

SC497: Temperature and Humidity Sensor Error

SC400: ID Sensor Error 1: Calibration

SC418: LED Error during Vsg Adjustment

SC410 to 413: ID Sensor Error 2 to 5: Development Gamma

SC414 to 417: ID Sensor Error 6 to 9: Development Start Voltage

Update Toner Supply Control

Parameters (During Copy Interval

Process Control Self-Check)

Determine Target Toner Amount Based

Using Development Gamma

Lower

Development

Gamma

Raise

Development

Gamma

Raises the

target setting

of the copy

interval

pattern, and

increases toner

concentration

Lowers the

target setting

of the copy

interval

pattern, and

decreaes toner

concentration

-or-

SC432 to 435: Potential Sensor Error 1 to 4: Vr

SC420 to 423: Potential Sensor Error 1 to 4: Vd Adjustment

SC424 to 427: Potential Sensor Error 5 to 8: Vl Adjustment

SC410 to 413: ID Sensor Error 2 to 5: Development Gamma

SC414 to 417: ID Sensor Error 6 to 9: Development Start Voltage

ID Sensor Detects Potential Sensor Detects

Temperature/Humidity

Sensor Detects

Detect VdHome

Adjust AC Charge

(Charge Roller)

Agitate Developer

Adjust Vsg

Potential Sensor Reads

Unexposed Pattern on Drum

ID Sensor Reads Developed

Pattern on the ITB

Adjust for Residual Potential, Calibrate Vr

Vd* Vb* Vpl*

Adjust Vd Adjust Vpl

ID Sensor Reads Pattern

TD Sensor Detects

Vtcnt/Vtref Calibration

2

1

3

4

5

6

7

8

9

B132D988.WMF