Xerox Nuvera Paper Guide

2-2

Managing your paper supply

• Edge welds (edges stuck together) - If edge welds are present,

the paper was not cut properly and will jam in the press.

• Creased, wrinkled, torn, or folded sheets - Sheets must be

intact and perfectly flat to run reliably.

• Drilled paper that does not separate easily, or has paper plugs

left in the holes - Drilled paper must be drilled cleanly to run

reliably in the system.

• Dust or chaff in perforated papers, or areas around

perforations that are not flat - Perforated papers should be free

of paper dust and chaff (bits of paper), which can contaminate

the system. The bulge beneath the perforations should be

flattened as much as possible to avoid paper jams and image

quality problems.

Handling paper

Even the best papers can be rendered useless by improper

handling. Paper damage, caused by poor handling, may not be

apparent until feeding or image quality problems occur.

Protect your paper investment by following these paper handling

tips:

• Never drop, throw, or strike cartons with a forklift.

• Handle individual reams gently and carefully.

• Never place a carton or ream of paper on its side or edge.

• When stacking cartons or reams, place them carefully on top

of one another to avoid crushing the edges.

• Store paper on surfaces that are flat and smooth to avoid

damage to the bottom sheets.

• To avoid damaging paper, never stack cartons and pallets too

high. Coated papers are especially susceptible to damage due

to the smooth surfaces and increased weight. Follow the

guidelines in Table 2-1. when stacking cartons and pallets.

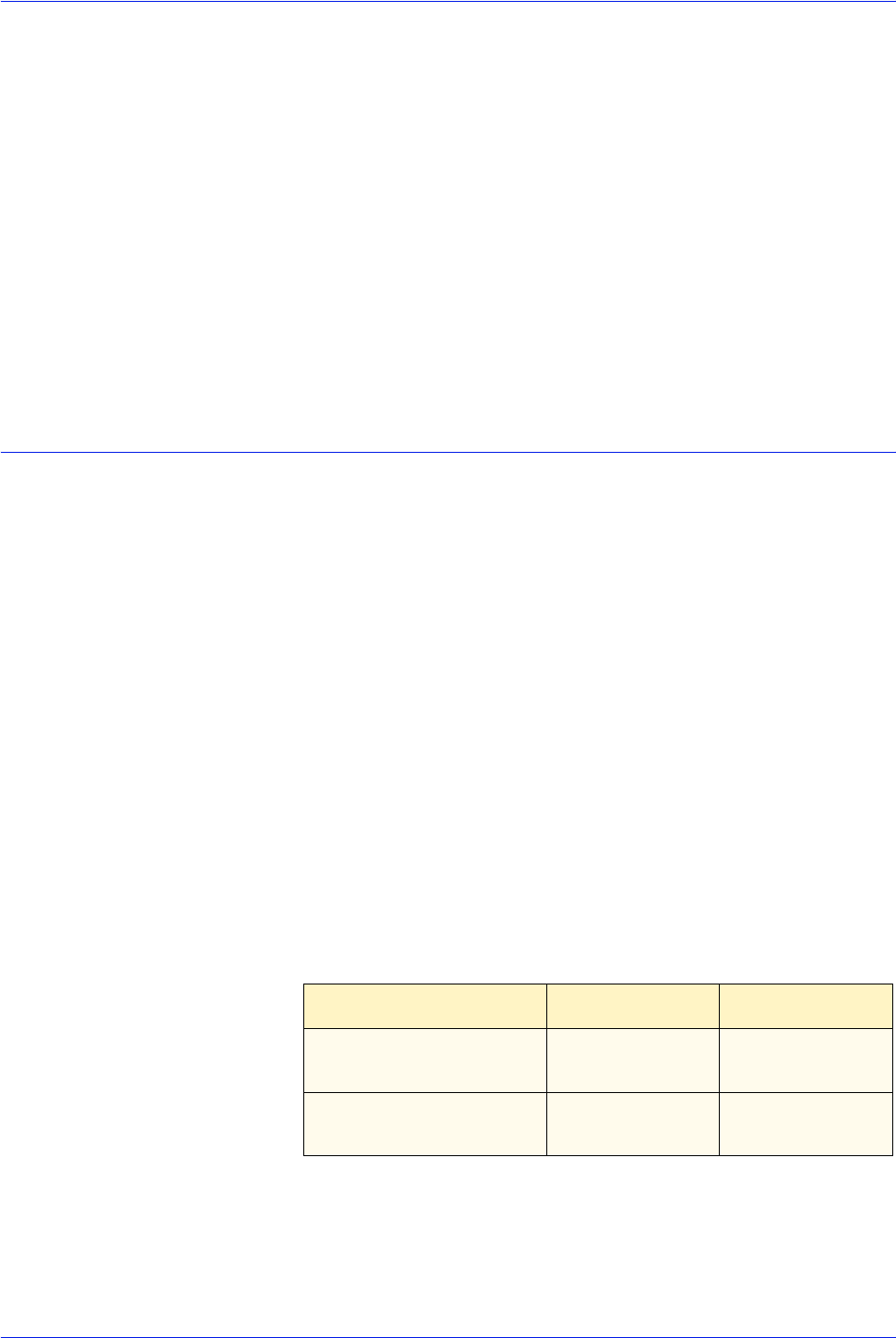

Table 2-1. Stacking limits

Items to be stacked Coated Paper Uncoated Paper

Maximum number of

Cartons

3 5

Maximum number of

Pallets

Do not stack 2