Xerox Nuvera Paper Guide

2-7

Managing your paper supply

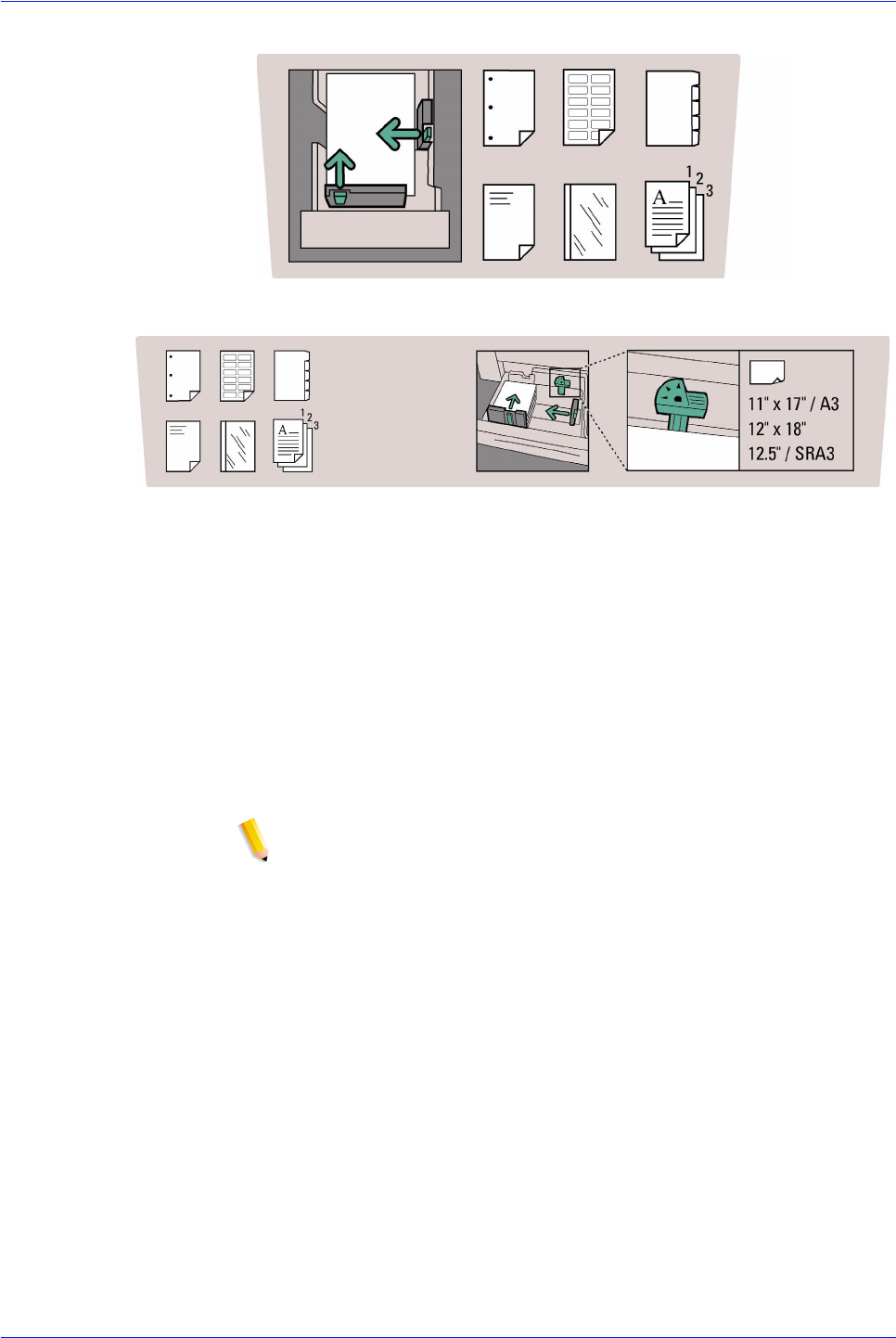

Figure 2-2. Stock Loading Label for Trays 1 and 2

Figure 2-3. Stock Loading Label for Trays 3 and 4

The following are general stock loading tips:

• Never open reams or cartons of paper until you are ready to

load the paper into a feeder tray. Reams and cartons provide a

barrier to moisture, which ensures proper paper handling and

image quality.

• The stock that you load into a feeder tray must match the tray

programming. The tray can be programmed prior to loading

the paper, or the paper can be loaded first and the tray

programmed later. Refer to the Configuring Paper Stocks and

Tray Settings section in the Xerox Nuvera User Guide and

Training Aid online.

NOTE: When programming a stock in a feed tray or the stock

library it is important to set the correct stock properties, especially

the weight listed as gsm. Based on the weight of the stock (gsm)

setting, the feed tray ‘fluffers’ settings are modified to feed the

programmed stock. Taking time to verify the gsm setting

increases runtime and productivity by decreasing feed module

paper jams.

• Inside the feeder tray, move the paper guides away from the

stack before adding or removing stock. This will help you

prevent damage to the guides and the paper.

• Adjust the side and trail edge guides snug against the stack

after loading the first ream of paper then fill the remainder of

the tray.

• Ensure the finger of the stack height sensor is free and rests

above the top of the stack.

• Loading papers of varying types and weights may warrant

manual adjustment of the decurler mechanism. Refer to the

Adjusting the Decurler section in the Xerox Nuvera User Guide