Xerox Nuvera Paper Guide

2-6

Managing your paper supply

• Start up the production system by following the Powering On

the Xerox Nuvera procedure in the Xerox Nuvera User Guide

and Training Aid online.

Conditioning paper to the printing environment

When paper is moved from a storage area to a print room, it must

be conditioned to the print room temperature before it is used.

Conditioning means allowing the paper to stand, unopened, in the

print room until its temperature matches the temperature of the

print room.

NOTE: Properly conditioning paper is the most important thing

you can do to improve paper handling.

Jamming, due to paper curl, and degraded image quality, due to

paper expansion, are common problems when paper is not

adequately conditioned.

The times in Table 2-3. should be considered minimum

conditioning times and must be followed to obtain optimum

performance.

Conditioning can be accelerated by removing the reams from the

cartons - but never open the reams until you are ready to print.

Loading paper into feeder trays

For the best possible paper handling and image quality, you must

use proper techniques when loading paper into feeder trays.

Each feeder tray has a stock loading label (Figure 2-2. and Figure

2-3.) that is visible when the tray is opened. Refer to the label for

help in loading different sizes and types of stock. Also refer to

Chapter 3, Tips by stock type, for tips on loading specific types of

stock.

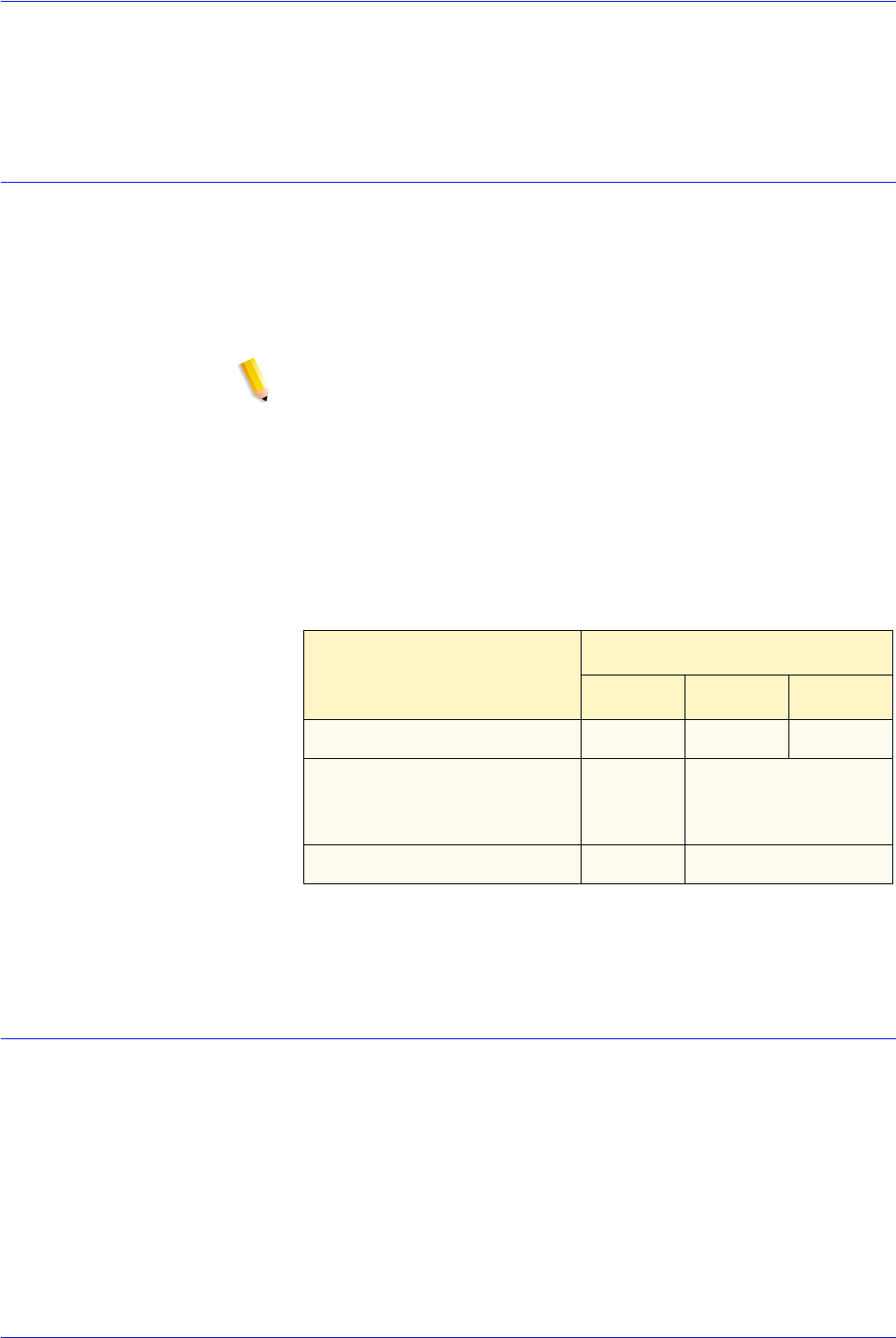

Table 2-3. Paper conditioning times

Type of stock

Minimum conditioning times

Reams Carton Pallet

Uncoated stock 4 hours 24 hours 72 hours

Coated and specialty stocks

(labels, envelopes, films,

etc.)

24 hours 72 hours

Transparencies 4 hours 24 hours