10 Specifications

10-10 Xerox PE220

• Paper should be stored at or near room temperature.

• The air should not be too dry or too humid.

• The best way to store an opened ream of paper is to rewrap it tightly in its

moisture-proof wrapping. If the machine environment is subject to

extremes, unwrap only the amount of paper to be used during the day’s

operation to prevent unwanted moisture changes.

Envelopes

Envelope construction is critical. Envelope fold lines can vary considerably,

not only between manufacturers, but also within a box from the same

manufacturer. Successful printing on envelopes depends upon the quality of

the envelopes. When selecting envelopes, consider the following

components:

• Weight: The weight of the envelope paper should not exceed 20 lb (75 g/

m

2

) or jamming may occur.

• Construction: Prior to printing, envelopes should lie flat with less than 0.25

inches (6 mm) curl, and should not contain air.

• Condition: Envelopes should not be wrinkled, nicked or otherwise

damaged.

• Temperature: You should use envelopes that are compatible with the heat

and pressure of the machine.

• Size: You should only use envelopes within the following size ranges.

NOTE:

• Load only one envelope at a time to print envelopes.

• You may experience some paper jams when using any media with a

length less than 5.5 in. (140 mm). This may be caused by paper that has

been affected by environmental conditions. For optimum performance,

make sure you are storing and handling the paper correctly. Please refer

to Paper Storage Environment on page 10-9..

Envelopes with Double Side Seams

Double side-seams construction has vertical seams at both ends of the

envelope rather than diagonal seams. This style may be more likely to wrinkle.

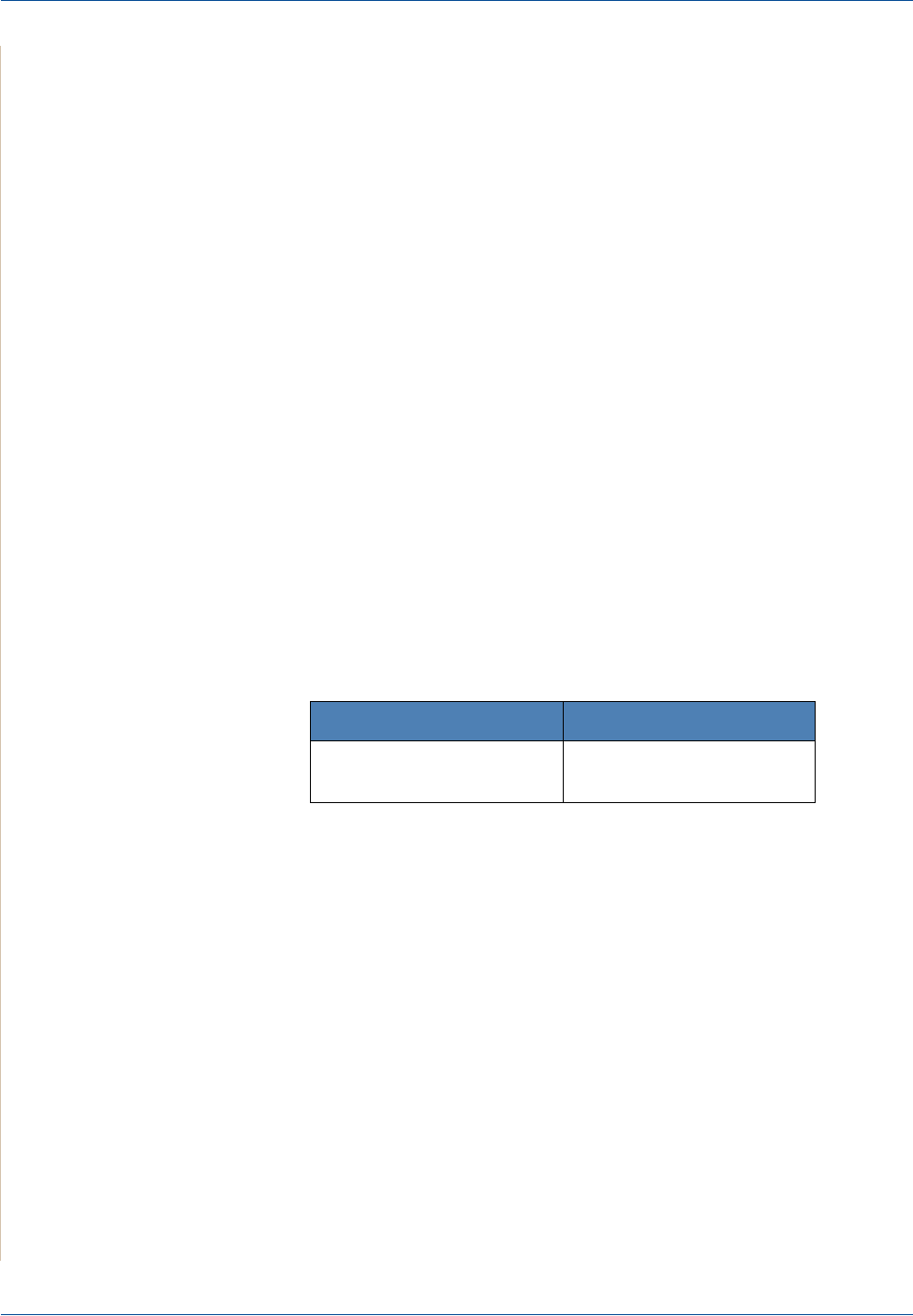

Minimum Maximum

3 x 5 in.

(76 x 127 mm)

8.5 x 14 in.

(216 x 356 mm)