Chapter 3 Disassembly and Maintenance

3-6. Adjustments

CL-S700/CL-S703/CL-S700R 3-58

12) Remove the “Ribbon-tension spring adjust ribbon (φ80mm)” and reset the “Ribbon-tension

adjust ribbon (φ60mm)”.

13) Hook a spring gauge of 500gf on the “Ribbon-tension adjust ribbon (φ60mm)” and slowly

pull the ribbon end downward at a constant speed (approx. 7.5cm/sec. or so). Then, check

if the reading of the spring gauge in the steady state is within 450 +/- 50gf.

If the reading is out of the specified range, repeat above sub steps 4) through 11).

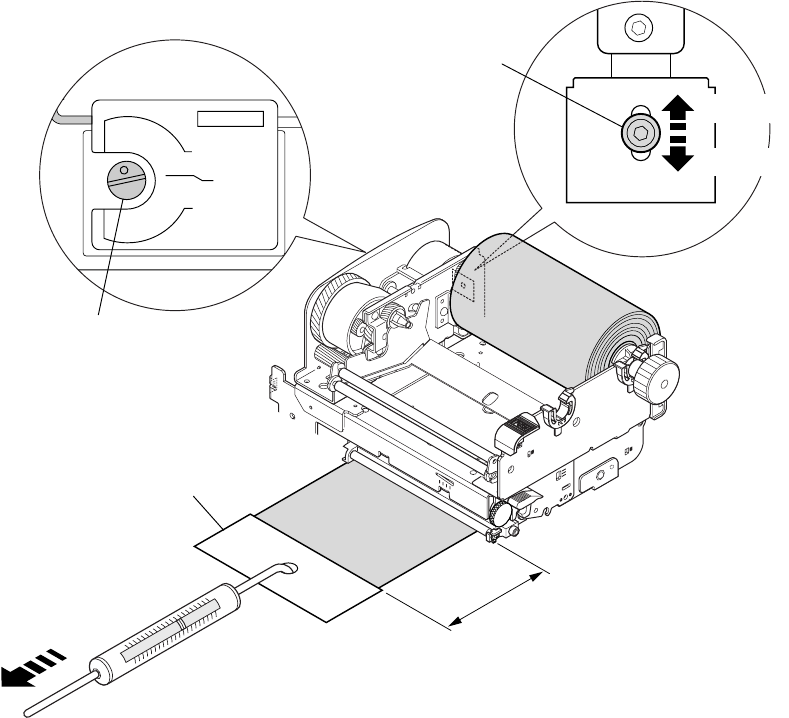

5. Ribbon Tension Check/Adjustment on Supply Side:

1) Set the “Adjust screw for Supply side ribbon tension adjustment” to “STANDARD” position.

2) Set the “Ribbon-tension adjust ribbon (φ60mm)” to the supply side ribbon holder.

3) Hook a spring gauge of 500gf on the “Ribbon-tension adjust ribbon” and horizontally pull

the ribbon end toward you at a constant speed (approx. 7.5cm/sec. or so).

When the ribbon is drawn approx. more than 20cm, suddenly load applies to the spring

gauge. With this load condition, check if the reading of the spring gauge is within 400 +/-

50gf.

4) If the reading is in the specified range, no tension adjustment on supply side is required. In

this case, proceed to step 6. If not, proceed to the next sub step.

5) Apply ThreeBond 1401B to the Adjust screw “D” after removing it. Then, loosely tighten the

Adjust screw “D” with a hex wrench and leave the hex wrench on the Adjust screw “D”.

6) While repeating above sub step 3), adjust the position of Adjust screw “D” by moving hex

wrench up and down so that the reading of spring gauge is within 400 +/- 50gf.

TENSION

STANDARD

LOW

SUPER LOW

Adjust screw for Supply side

ribbon tension adjustment

400 +/- 50gf

Approx. 20cm

Ribbon-tension adjust ribbon (φ60mm)

Adjust screw "D"

(For Service)

[Supply side adjustment]

When strong

When weak