Manual Close Delay

Manual Close Delay provides a delay from the time that

the manual CLOSE button is pushed to the time the man-

ual close operation is performed.

The delay is programmable from 0 to 60 seconds in 1 sec-

ond increments. A programmed delay value can be over-

ridden for immediate closing by pressing the CLOSE

button a second time.

An active Manual Close Delay can be canceled by press-

ing the TRIP/LOCKOUT button.

The default setting has the feature disabled (0 seconds).

The RECLOSER CLOSED LED indicates the status of the

feature. See Figure 11.

Harmonic Analysis

Extensive harmonic analysis is performed by the Form 5

control for both currents and voltages. Analysis is per-

formed on-line (updates every 30 seconds) or demand

integrated to user-specified time values. The Total Har-

monic Distortion (THD) for current and voltage is available

from the operator panel display (Figure 12) while com-

plete analysis, including graphing capabilities, is provided

from the Form 5 interface software.

Reverse Power Flow

Feeder load monitoring is enhanced with the inclusion of

the power flow monitoring feature. When power flow from

the load to the source side of the recloser is detected, the

control illuminates an operator-panel indicator. Response

time to a reverse power condition is one second. An alarm

is also available for remote interrogation.

Note: Voltage sensor polarity must be correct for reverse

power flow to function properly.

Event Recorder

The Event Recorder maintains a log of operating events

for later readout and analysis by the user. Approximately

500 events can be stored in non-volatile memory. For

each event type, time of occurrence, and other relevant

information is stored. When the event recorder has

reached is capacity, the oldest event is deleted as a new

event is added.

Histograms

Demand metered voltages and currents can be reported

using the histogram tool. It displays the number of occur-

rences of a variable versus its value in between user-

defined minimum and maximum limits. Date and time are

recorded for the maximum and minimum demand values.

Data Profiler

A fully configurable data profiler is available which allows

the user to collect information by sampling demand data

at selectable intervals. These time-stamped values can

then be plotted to determine weekly load profiles, daily

harmonic disturbances or hourly voltage fluctuations. The

data profiler can provide more than 200 days of informa-

tion, depending upon configuration parameters.

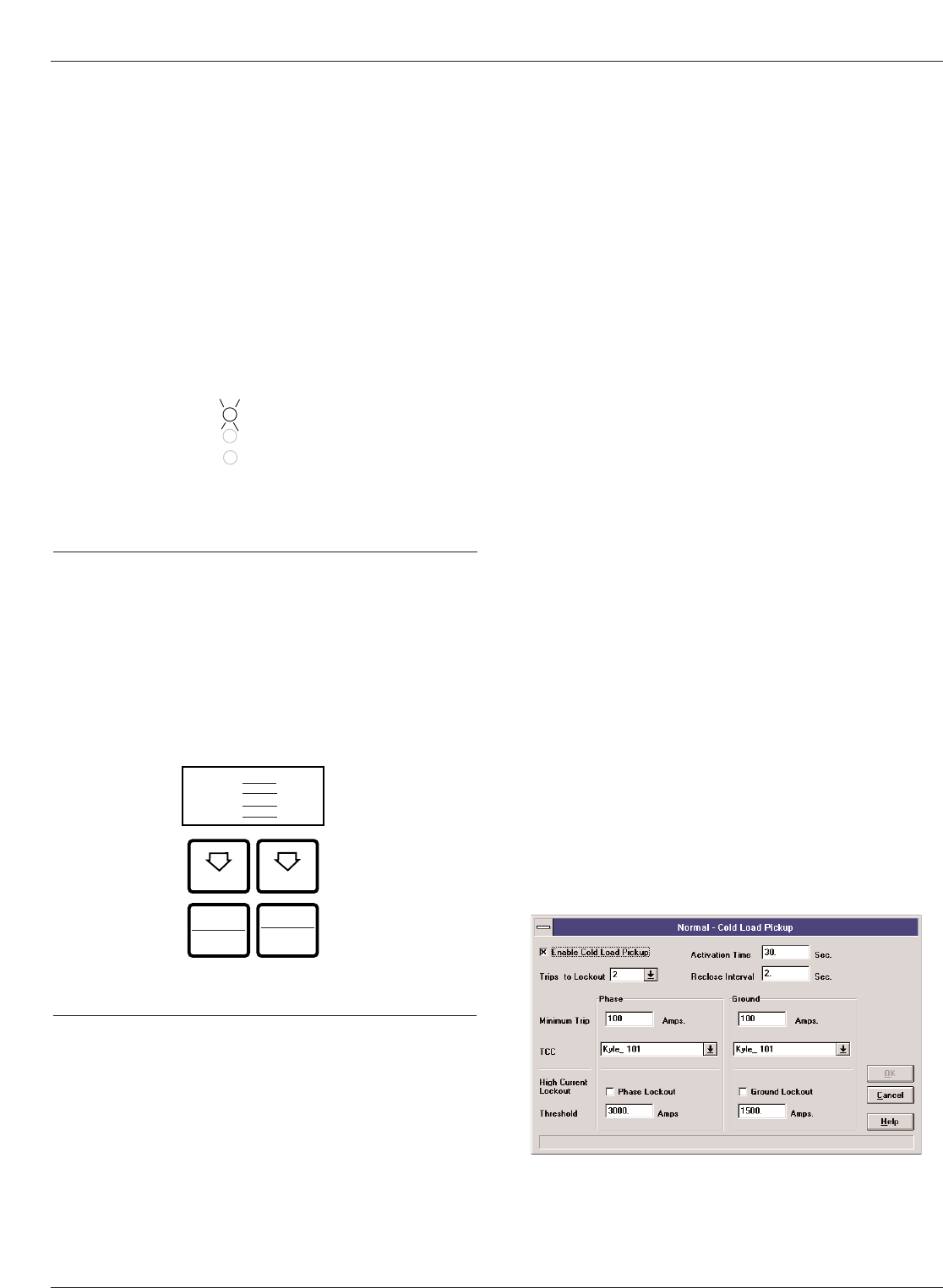

Cold Load Pickup

Cold Load Pickup (CLPU) must be enabled through the

interface software (Figure 13) before it can be activated

remotely or from the CLOSE pushbutton on the operator

panel. The CLPU feature provides the user with the abil-

ity to alter protection for abnormal system conditions. It is

active for a programmable time interval which begins with

each manual close. Once this time elapses, protection

reverts back to the programmed sequence. Use the Form

5 control interface software to program the activation time

and time-current characteristics applicable to Cold-Load

Pickup.

Note: When CLPU is active, the control utilizes the Cold Load

Pickup TCC, reclose interval, operations to lockout, and

minimum trip settings in lieu of the normal protection

settings.

Kyle Form 5, Form 5 UDP, Form 5 DC NOVA Recloser Control Installation and Operation Instructions

16

Figure 13.

Interface software Cold Load Pickup settings.

Figure 12.

Form 5 operator panel harmonic readout.

NEXT

BACK

RESET

TARGETS

CHANGE

Pg14 Gnd %THDI

Ph1-2 %THDI

Ph3-4 %THDI

Ph5-6 %THDI

RESET

MAX CURRENT

LAMP

TEST

RECLOSER CLOSED

RECLOSER OPEN

CONTROL LOCKOUT

Figure 11.

The blinking of the RECLOSER CLOSED LED indi-

cates Manual Close Delay is active.