Closing the Recloser During

Testing

Electrical Closing—Solenoid-Operated

Reclosers

Line voltage is required for automatic recloser operation

during testing of reclosers equipped with a closing

solenoid (except for reclosers equipped with the low volt-

age closing accessory).

For on-line testing, bypass the recloser, open the load-

side disconnects and keep the source-side disconnects

closed. This will remove the recloser from service, but will

keep line voltage supplied to the closing solenoid (Figure

44).

For shop testing, the closing solenoid voltage is supplied

by back-feeding a transformer with a low-side rating equal

to the voltage rating of an available power source, and a

high-side rating equal to the voltage rating of the recloser

(Figure 45). A 75kVA transformer of the proper voltage

rating with an impedance drop of approximately 3% is sat-

isfactory. The ac source must have a comparable

impedance drop.

The closing coil requirement is approximately 200kVA

during the two-to-three cycle closing operation. The

solenoid coil operating voltage must be maintained at the

recloser bushings during the cycle interval the closing coil

is energized. This procedure is not used on reclosers

equipped with the low-voltage closing accessory.

Electrical Closing—Motor-Operated

Reclosers

High-voltage is not required for reclosers utilizing a motor-

operated closing mechanism energized from a 230VAC

power source. For information on energizing the recloser,

refer to the appropriate motor-operated recloser installa-

tion manual.

Figure 43 shows a test circuit for motor-operated and

solenoid-closing reclosers with low-voltage closing. Since

these reclosers require only a 240 Vac source for closing,

high-voltage transformer T3 and its protective cage is

eliminated. All other equipment is the same as the test

equipment shown in Figure 42.

Electrical Closing—NOVA Reclosers

Type NOVA 3-phase reclosers utilize an interface circuit

located in the mechanism housing. The electronic inter-

face circuit controls the opening and closing signals to the

magnetic actuator.

The Dc NOVA Recloser is tested with the dc-to-dc con-

verter and 19-pin cable connected to the dc power supply.

Kyle Form 5, Form 5 UDP, Form 5 DC NOVA Recloser Control Installation and Operation Instructions

44

WARNING: Hazardous voltage. Solidly ground

all equipment. Failure to comply can result in

death, severe personal injury, and equipment damage.

T223.2

!

Figure 43.

Suggested test circuit for motor-operated, solenoid-

closing reclosers with low-voltage closing.

65

43

21

Electronic

Control

J

GK

H

XW

240 Vac

Power

Supply

Closing

Motor

T1 T2

240 Vac

Variable

Autotransformer

240 Vac-20 A

120 Vac

To Ammeter

and Relay

to operate

cycle counter or

other timing

device

Sensing CTs (3)

WARNING: Hazardous voltage. Interconnect

source leads X and Y and ground solidly to the

recloser tank (Figure 45). Do not connect lead Z to any

other phase or mechanical ground. Dangerous voltages

to ground exist on the phase connected to lead Z. Solidly

ground all equipment. Failure to comply can result in

severe personal injury and/or equipment damage. T224.1

!

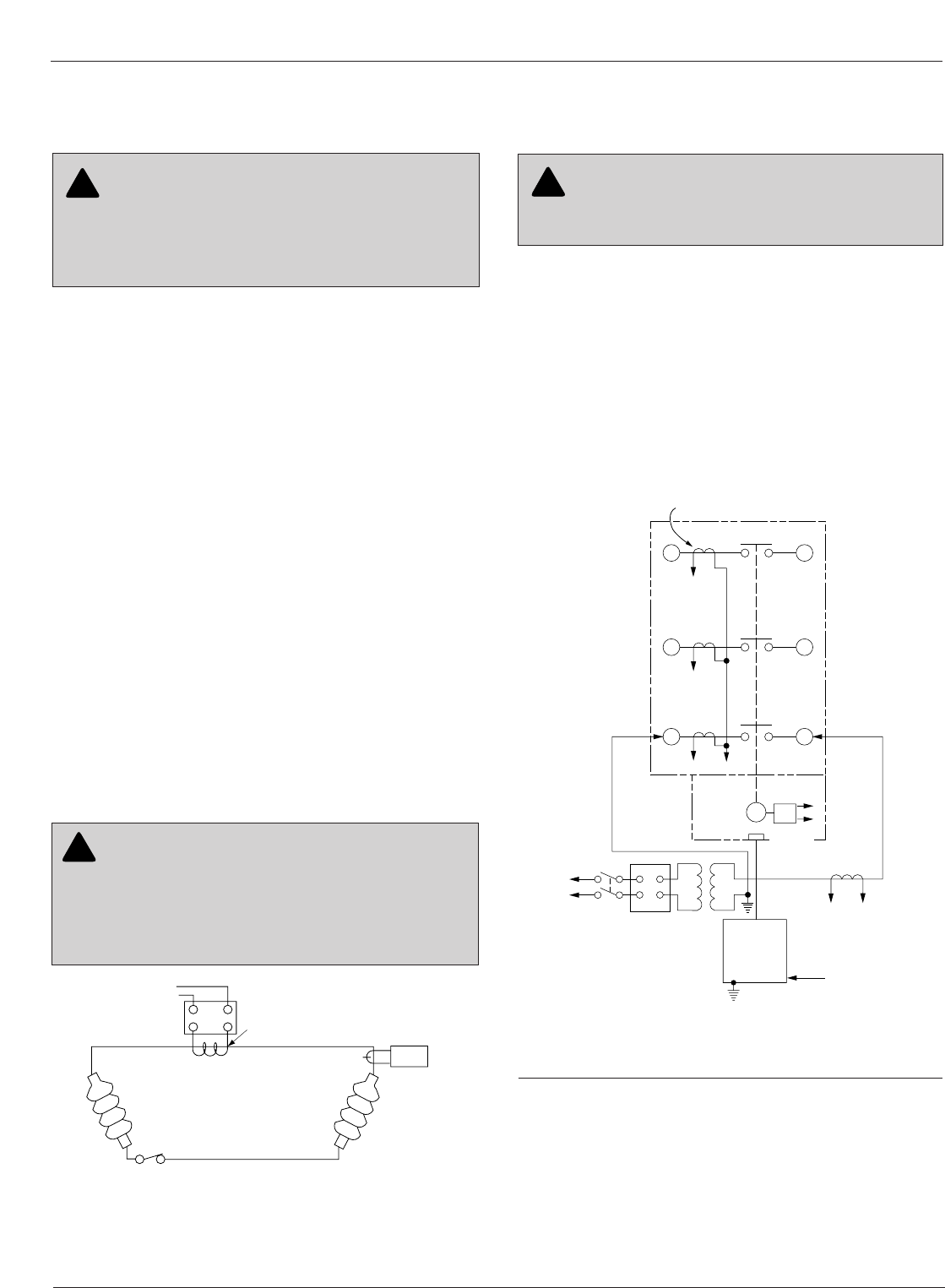

Figure 42.

Alternate method of producing variable line current

(substitute for T2 and W-X circuit in Figures 43 and

45).

600:5

Recloser

BCT ON 600:5 Tap

Note: This test circuit

can apply over

800 Amps to the

recloser.

Note: Use at least 2/0

cable between

bushings.

2

1

115Vac

Variable

Autotransformer

(10 Amp)

Clamp-On

Ammeter

WARNING: Hazardous voltage. The switchgear

and high voltage transformer must be in a test

cage or similar protective device to prevent accidental

contact with the high voltage parts. Solidly ground all

equipment. Failure to comply can result in death,

severe personal injury, and equipment damage. T221.3

!