Customer Connections for AC

Power

Input power to the Form 5 control is connected to terminal

block TB1 (located behind the operator panel, on the left

side of the control). See Figure 33.

Input power is required:

• To power the control

• To provide voltage and power metering

• For voltage detection for loop scheme accessory

• For the low voltage closing accessory

• For the convenience outlet accessory

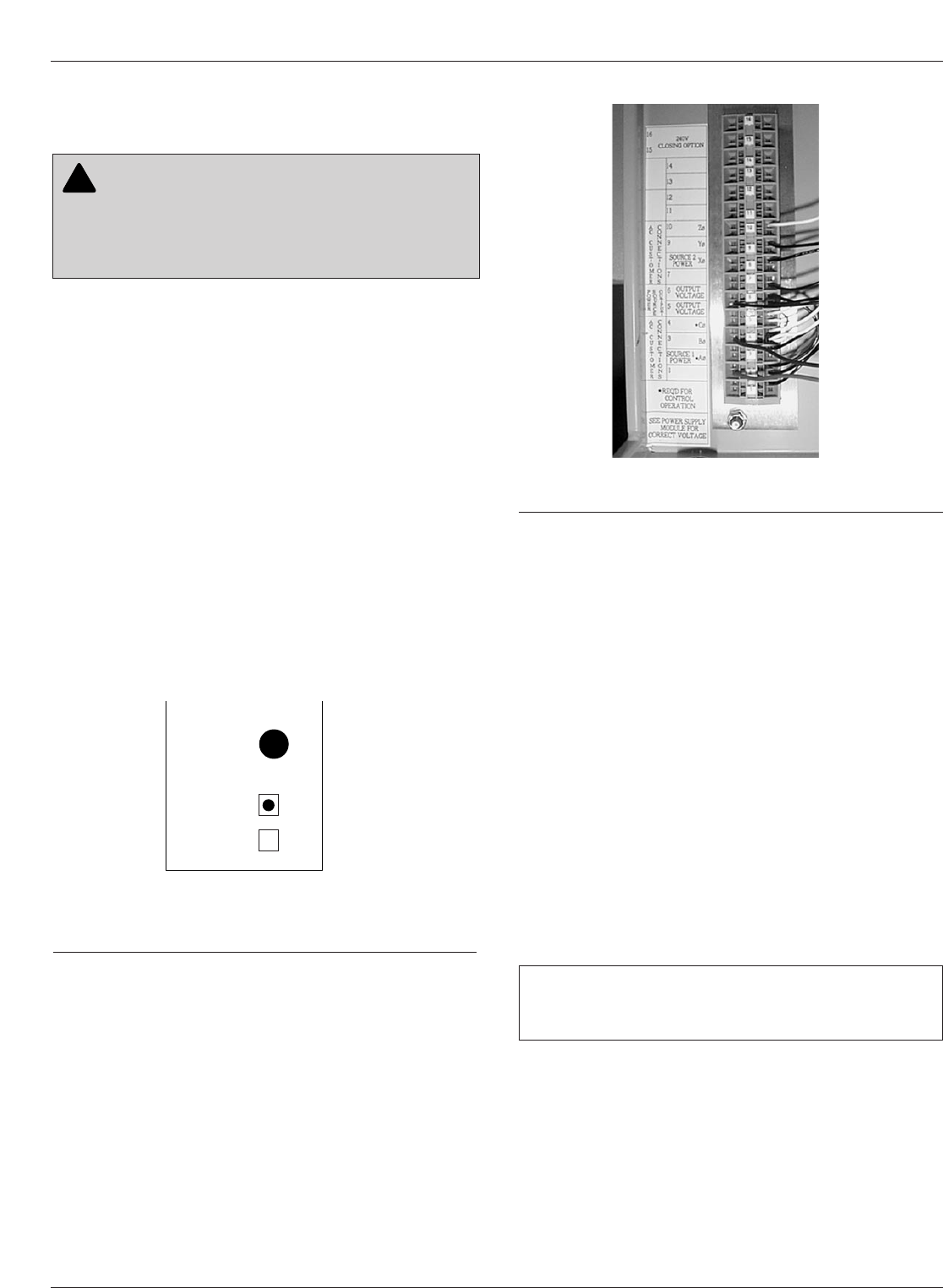

Power Supply Verification

Incoming power is routed to the Power Supply module

which is factory configured for either 120 or 240 volt oper-

ation. The power supply module is factory wired to TB-1

and protected by the 3.15 Amp fuse labeled F2 on the

power supply operator panel. A label on the Power Sup-

ply module indicates the proper voltage rating. See Figure

32.

Inserting and Releasing Wire

Connections

In Terminal Block TB1, each terminal has a wire locking

clamp that has to be opened to accept and secure the

wire. A 3/32 inch flat-blade screwdriver is inserted into

each terminal hole to open the locking clamp. Figure 34

provides the procedure for opening and securing the wire

connections.

The wire is inserted into the terminal connection hole

while the screwdriver is placed into the wire release and

locking hole.

Follow the same procedure to release wire connections.

Power Connections

Customer connections to TB1 vary upon application. TB1

connections provide power and metering inputs to the

control. Figures 34 through 39 show the customer con-

nections for 120 Vac and 240 Vac low voltage closing.

Figures 34 through 37 illustrate customer connections for

single-phase transformers. Figure 34 shows standard

wiring with BØ transformer connected to TB1-2 location.

Other phases should be connected from the single-phase

transformer by wiring the BLACK wire from the Power

Supply module to the terminal of the respective phase as

shown in Figure 38 and 39. For example, Figure 39 shows

connection from the Power Supply module to an AØ

transformer.

The transformer required for power should be a minimum

of 5kVA for low-voltage ac closing reclosers and 1kVA for

dc closing reclosers.

Note: An out-of-service Form 5 or Form 5 UDP control (for

either Wye or Delta) can be powered by connecting to

TB1-2 (hot) and TB1-4 (neutral) to an appropriate power

source.

Customer Connections for

Metering

Customer voltage inputs for metering are field config-

urable on the RIF module to accept 12, 120, or 240 Vac.

The incoming power supply must match the indication for

incoming power on the RIF module. The factory-config-

ured settings for the RIF are displayed on the module

panel. See Figure 19.

See RIF Module Configuration section of this manual.

Kyle Form 5, Form 5 UDP, Form 5 DC NOVA Recloser Control Installation and Operation Instructions

38

CAUTION: Equipment damage. Do not drill con-

nection holes into the top of the cabinet. Connec-

tion holes in the top of the cabinet will allow moisture to

seep into the control and damage the components or

cause control misoperation. Failure to comply will void

the control’s factory warranty. T249.0

!

Figure 33. 99003KM

Terminal Connector Block TB1.

IMPORTANT: Delta connections are not used on any

Form 5 control accessory that utilizes the low voltage

transfer relay.

Y

M

O

D

U

L

E

CONFIGURED

FOR

120

VAC

240

VAC

F2

GDC-3.15A

Figure 32.

Label on Power Supply module indicates factory-

configured voltage rating (120Vac).