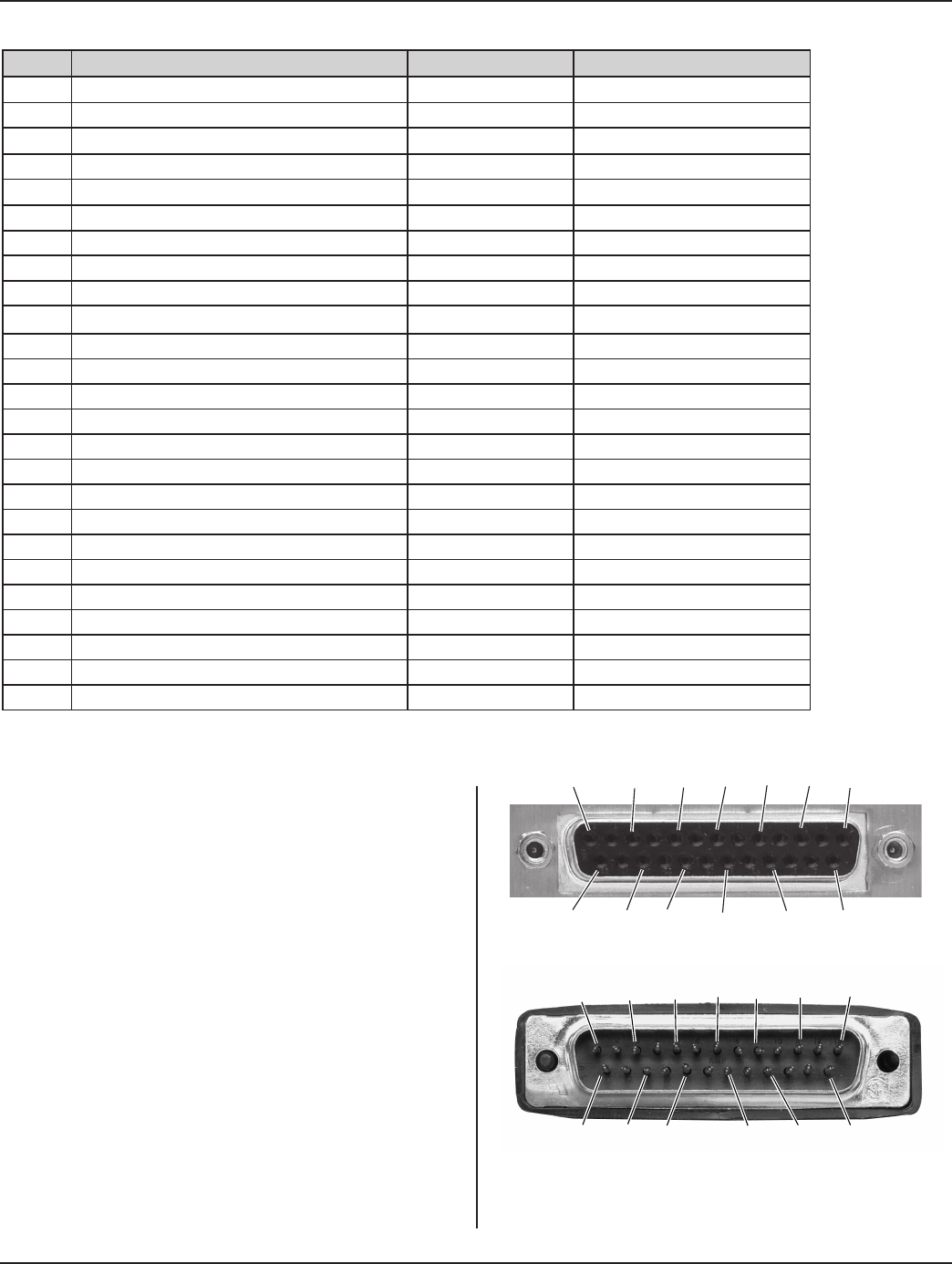

Pin Signal Name Cable Color Code Signal Option Requirements

1 +22V BLK

2 Spare Output WHT

3 +22V Power Ground RED

4 Programmable Status Output 1 GRN

5 Programmable Status Output 2 ORN

6 Ultrasound Active Status Output BLU

7 Any Fault Status Output WHT/BLK

8 Press Trigger Status Output RED/BLK

9 System Overload Status Output GRN/BLK

10 System Online Status Output ORN/BLK

11 Press Top of Stroke Status Output BLU/BLK

12 Current Loop OK Status Output BLK/WHT Not Used

13 Analog Monitor Signal Common RED/WHT

14 Not Used GRN/WHT

15 Power Signal Monitor Output BLU/WHT

16 Amplitude Monitor Output BLK/RED

17 Amplitude/Power Regulation Status Output WHT/RED

18 MPC Ready Status Output ORN/RED Not Used

19 System Power OK Status Output BLU/RED

20 Bad Part Status Output RED/GRN

21 Good Part Status Output ORN/GRN

22 System Ready Status Output BLK/WHT/RED

23 Suspect Part Status Output WHT/BLK/RED

24 Isolated Common RED/BLK/WHT

25 Not Used GRN/BLK/WHT

Table 3-III System Output Connector Signals (J3)

Figure 3–11 DB-25F, Generator Output Connector (J3)

Figure 3–12 DB-25M, Generator Output Cable

Connector

1 3 5 7 9 11 13

15 17 19

21 23 25

13 11 9 7 5 3 1

25 23 21 19 17 15

System Outputs Connector

The SYSTEM OUTPUTS connector mounted on the gen-

erator I/O panel includes connections for all of the basic

system status and monitor output signals, which will typi-

cally connect to an automated control system. The cable

attached to this connector includes all of the available

system output signals, which will be read or monitored by

a digital input card or analog inputs on the user-supplied

automation controller.

The user can determine which signals are appropriate for

each welding application.

The system monitor output signals are analog signals used

to monitor ultrasonic amplitude setting and ultrasonic output

power levels, referenced to the Monitor Common (Pin 13).

Continued

Page 23

Dukane Manual Part No. 403-575-00

Section 3 - Installation