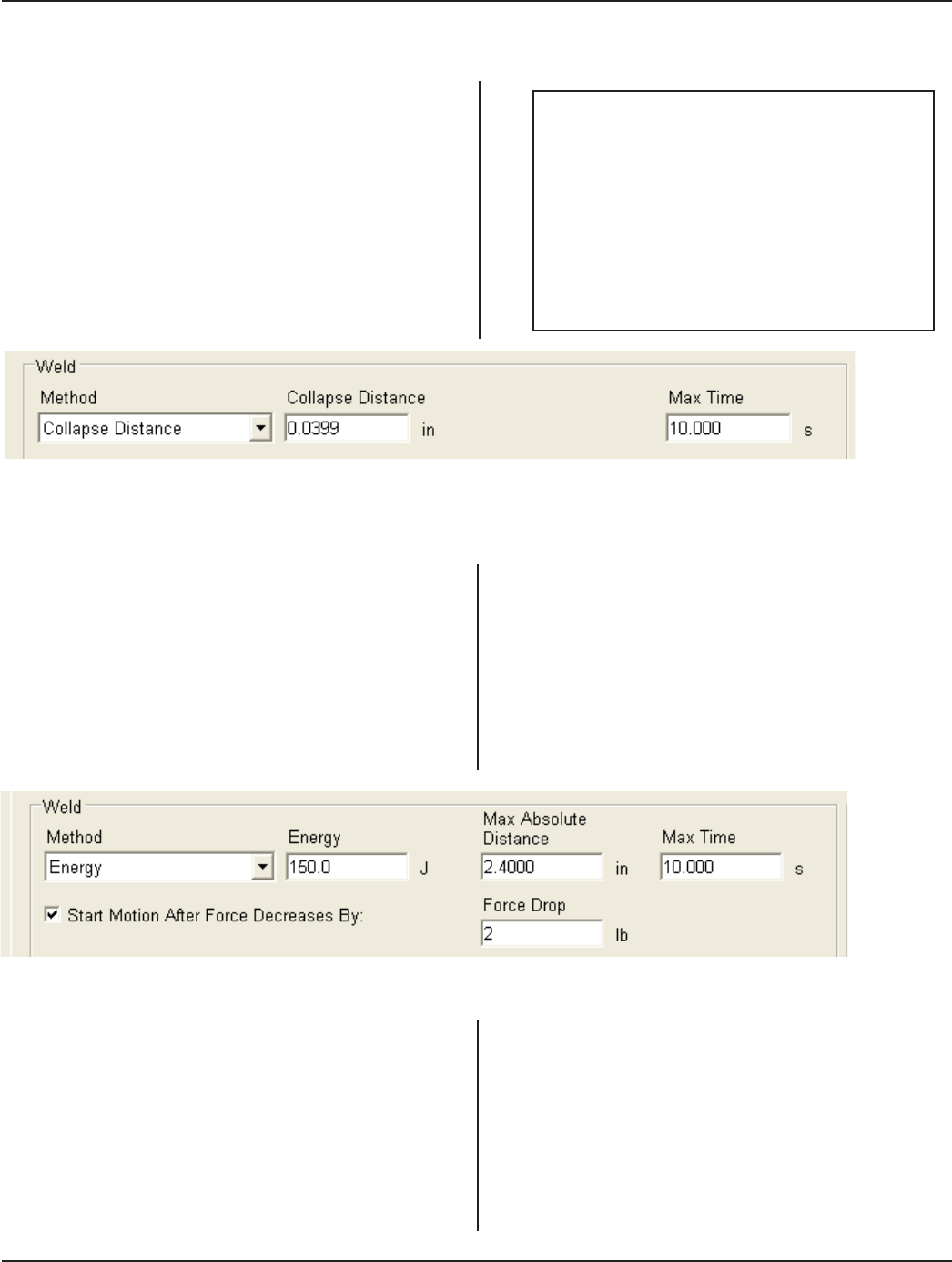

On the Process Settings tab, select Weld > Method,

Parameter, and Max Time.

Collapse Distance - The distance the welder advances

once programmed trigger force is reached. Usually the dis-

tance is the height of the energy director, or shear joint of

the part being welded.

Max Time - A secondary weld characteristic offering a

measure of safety. If the programmed parameter is not

achieved (as in the example shown in Figure 4-14) within

10 seconds, the system will fault.

Figure 4-14 iQ Explorer, Weld > Method > Parameter > Max Time

,

Programming these weld parameters

is similar to programming the DPC

IV Plus or other pneumatic systems.

Weld methods are: Time, Collapse

Distance, Absolute Distance, Energy

and Peak Power.

NOTE

Continuing with the Process Settings tab. . .

See Figure 4-15.

This patented feature is found only on Dukane's servo

press systems. If the feature is selected, the system will

stop motion once the desired Trigger Force is achieved.

The ultrasound will be initiated at this moment. Once

the programmed force drop is detected, the motion will

continue. This is the basis for Dukane's exclusive Melt-

Match™ technology.

Figure 4-15 iQ Explorer, Start Motion After Force Decreases By:

Benets - Figure 4 -15 illustrates that motion of the

thruster will not continue unless the system detects that

the trigger force has decreased by 2 pounds. In theory,

this force drop will occur as the plastic starts to melt. The

benet of this option is signicantly less stress on the

parts and stronger weld bonds.

Servo Step 10 - Program Weld Characteristics

Servo Step 11 - Program Start Motion After Force Decreases By:

Page 49

Dukane Manual Part No. 403-575-00

Section 4 - Operation