10-2

Recommended Installation Instructions

These instructions must be followed in order to

conform to the EMC Directive. Follow the usual

safety procedures when working with electrical

equipment. All electrical connections to the filter,

Inverter, and motor must be made by a qualified

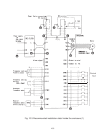

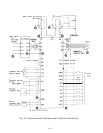

electrical technician. (Refer to Fig.2, Fig. 3, and

Fig.4)

1. Check the filter rating label to ensure that the

current, voltage rating, and part number are

correct.

2. The back panel of the wiring cabinet board should

be prepared for the mounting dimensions of the

filter. Care should be taken to remove any paint

etc. from the mounting holes and face area

around the hole of the panel. This will ensure the

best possible earthing of the filter.

3. The filter should be securely mounted in position,

and the Inverter mounted to the front of the filter

with the screws provided.

4. Connect the incoming main supply to the filter

terminals marked “LINE” and any earth cables to

the earth stud provided. Fit the Input Ferrite Ring

(if two ferrite rings are required, refer to table 1),

and connect the filter terminals marked “LOAD” to

the main input of the of the Drive using a short

length of appropriate gauge wire.

5. Fit the output Ferrite Ring as close to the Inverter

as possible and connect the motor. Armored or

screened cable should be used with the 3 phase

conductors passing twice through the center of

the Output Ferrite Ring. The earth conductor

should be securely earthed at both the ground

terminal in the cabinet and at the motor ends. The

screen should be connected to the enclosure.

6. It is important that all lead lengths are kept as

short as possible and that incoming mains and

outgoing motor cables are kept well separated.

7. Segregate power cables from control wiring, as

thoroughly as possible, and avoid parallel cable

run to minimize ‘noise coupling’. When ever runs

of power and control cable must cross, try to

achieve this at right angles.

8. Micro-$aver II Drive should be installed, and are

designed to operate, with an electrically -

shielded metal enclosure.

Fig. 10-2 Recommended installation

Drive