Piping Schematics

82

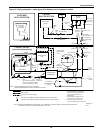

9.0 PIPING SCHEMATICS

Figure 57 Piping schematic—air-cooled, semi-hermetic compressor models

Condenser Coil

(Lee-Temp)

Condenser Coil

(Fan Speed)

Check Valve

Relief Valve

Service

Valve

Liquid Return

Head Pressure

Control Valve

Lee-Temp Receiver

Hot Gas Discharge

Evaporator Coil

Lee-Temp

Compressor

Muffler

Service

Valve

External

Equalizer

Liquid

Sensing

Bulb

Inverted trap on discharge and liquid

lines to extend above base of coil by

a minimum of 7-1/2” (190mm).

Field-installed relief valve (s)

required for 50Hz EU CE units rated

maximum 480 PSIG (33 Bar).

* Isolation

valve

* Isolation

valve

** Muffler

* Traps every

25ft (7 .6m)

of rise

Fusible

Plug

Suction

Hot Gas Discharge

Liquid Return

Filter Dryer

Sight Glass

Solenoid

Valve

Expansion

Valve

Refrigerant Piping

Field Piping

Service/Schrader (Access) Connection No Valve Core

Note: Schematic representation shown . Do not use for specific connection locations .

Two refrigeration circuits provided . Single refrigeration circuit shown for clarity .

Service

Valve

Cylinder

Unloader (s)

DPN000797

Rev. 3

Service/Schrader (Access) Connection With Valve Core

Components are not supplied by

Liebert, but are recommended for

proper circuit operation and

maintenance.

Components supplied by Liebert and

must be field-installed (70kW, 77kW

and 105kW models only).

*

**