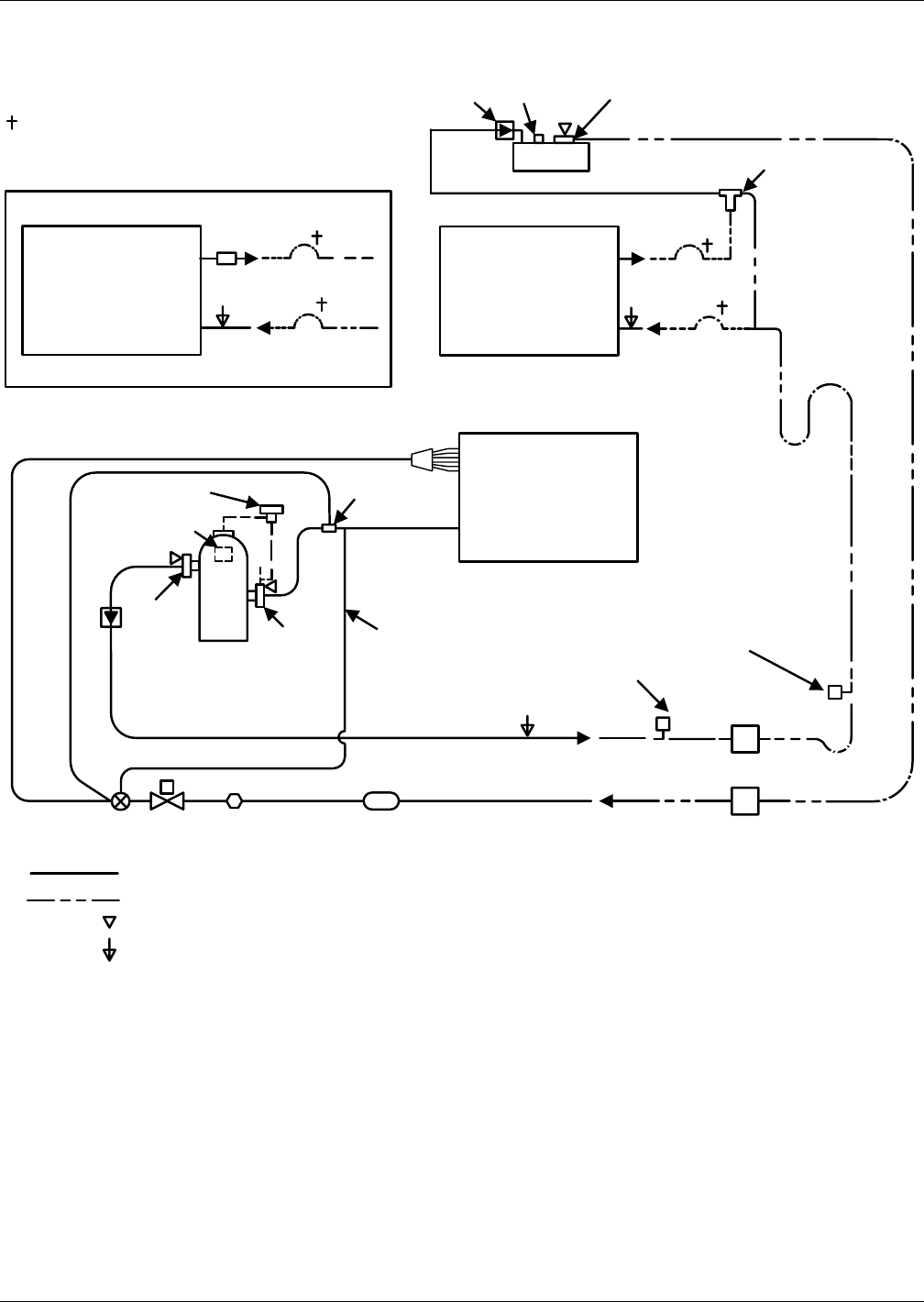

Piping Schematics

83

Figure 58 Piping schematic—air-cooled, scroll compressor models

Lee-Temp Receiver

Fan Speed

Lee-Temp

Service

Valve

External

Equalizer

Liquid

Sensing

Bulb

Inverted trap on discharge & liquid

lines to extend above base of coil

by a minimum of 7-1/2” (190mm).

Field installed relief valve (s) required

for 50 Hz EU CE units rated

maximum 480 PSIG (33 Bar).

* Isolation

valve

* Traps every

25ft (7.6m)

of rise

Fusible

Plug

Suction

Hot Gas Discharge

Liquid Return

Filter DryerSight Glass

Solenoid

Valve

Expansion

Valve

DPN000798

Rev. 2

Condenser Coil

(Fan Speed )

Condenser Coil

(Lee-Temp)

Evaporator Coil

Compressor

Service

Valve

Check

Valve

* Isolation

valve

(Required with Digital Scroll)

28-42kW Digital Solenoid Valve

53-70kW Digital

Solenoid Valve

Refrigerant Piping

Field Piping

Service/Schrader (Access) Connection No Valve Core

Note: Schematic representation shown . Do not use for specific connection locations .

Two refrigeration circuits provided . Single refrigeration circuit shown for clarity .

Service/Schrader (Access) Connection With Valve Core

Liquid Return

Hot Gas

Discharge

Head Pressure

Control Valve

Check

Valve

Relief

Valve

Service

Valve

Components are not supplied by

Liebert, but are recommended

for proper circuit operation and

maintenance.

*