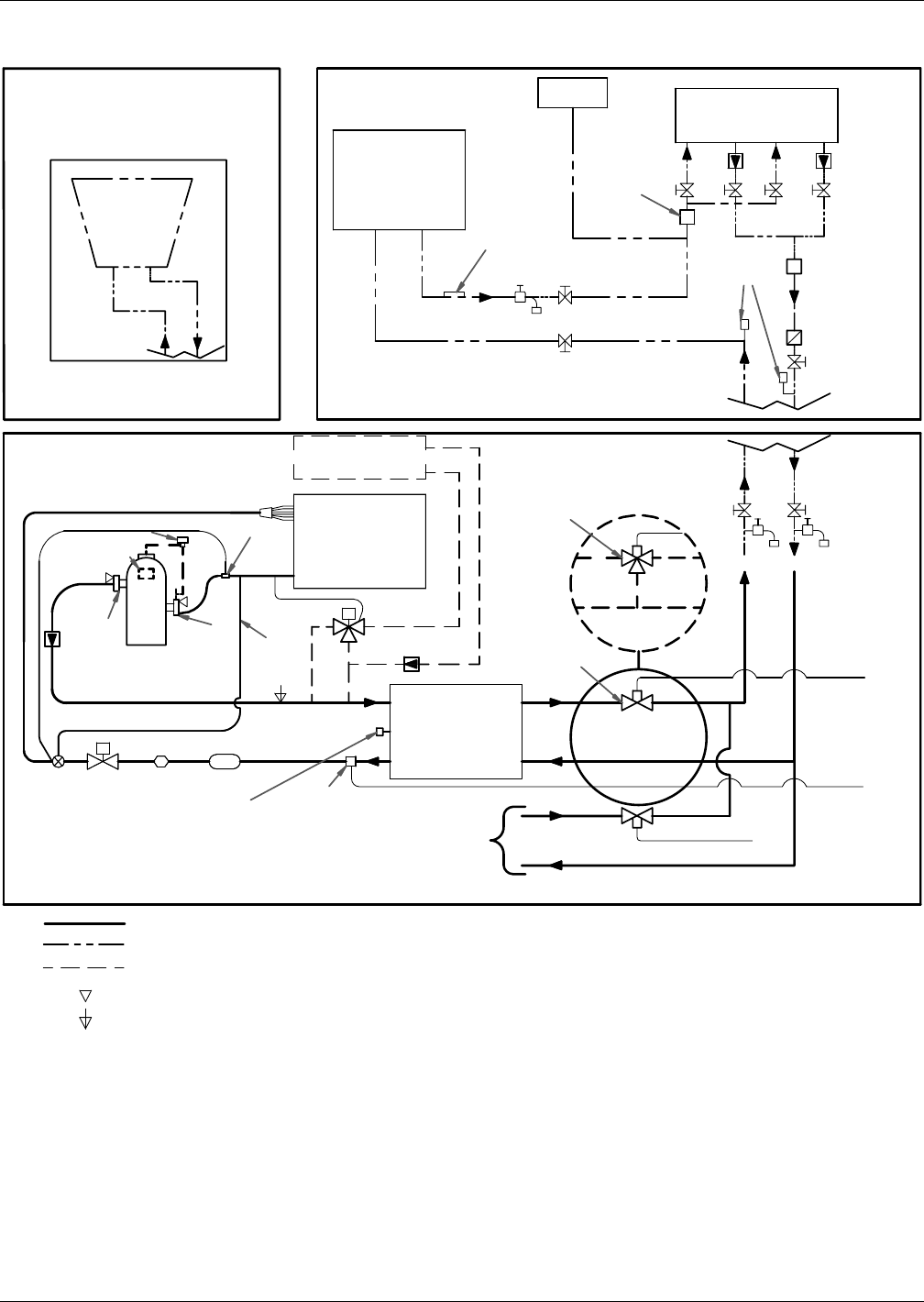

Piping Schematics

88

Figure 63 Piping schematic—water/glycol with digital scroll compressor models

Sensing Bulb

CUSTOMER

HEAT REJECTION

LIEBERT

HEAT REJECTION

LIEBERT DS UNIT

(and associated piping)

COOLING TOWER

AND PUMP

SYSTEM

BY OTHERS

RETURN SUPPLY

EXPANSION

TANK**

DRYCOOLER

(Glycol)

GLYCOL

PUMPS

Optional Dual Pump System shown

CheckValves*

(on Dual Pump

Systems only)

Gate Valves*

Pressure Port*

Flow Switch

Supplied with Dual

Pump Systems

Flow-Regulating

Valve*

Aquastat

Sensing

Bulbs

Hose

Bib*

Shut-Off Valve*

Shut-Off Valve*

Pressure

Port*

Air Vents

(typical)***

RETURN SUPPLY

HOT GAS REHEAT

LIQUID

28-42kW Digital Solenoid Valve

53-70kW Digital

Solenoid Valve

Service

Valve

Check

Valve

COMPRESSOR

DISCHARGE

Service

Valve

SUCTION

EVAPORATOR

COIL

PARADENSER®

CONDENSER

External

Equalizer

Hot Gas Reheat

Valve

Check Valve

Expansion

Valve

Solenoid

Valve

Sight

Glass

Filter Drier

Relief valve(s) supplied

with 50 Hz EU CE units rated

maximum 480 PSIG (33 Bar).

Pressure

Transducer

NOTE: TWO REFRIGERATION CIRCUITS PROVIDED

SINGLE REFRIGERATION CIRCUIT SHOWN FOR CLARITY.

TO SECOND

REFRIGERATION

CIRCUIT

Optional 3-Way

Motorized Ball

Valve

Shut-Off Valve* Shut-Off Valve*

Hose

Bib*

Hose

Bib*

2-Way

Motorized

Ball Valve

From

iCOM

Control

To

iCOM

Control

RETURN SUPPLY

FACTORY PIPING

FIELD PIPING

OPTIONAL FACTORY PIPING

SERVICE / SCHRADER (ACCESS) CONNECTION NO VALVE CORE

SERVICE / SCHRADER (ACCESS) CONNECTION WITH VALVE CORE

NOTE: SCHEMATIC REPRESENTATION SHOWN. THIS SCHEMATIC DOES NOT IMPLY OR DEFINE ELEVATIONS AND

COMPONENT LOCATION, UNLESS SPECIFICALLY NOTED.

* Components are not supplied by

Liebert but are recommended for

proper circuit operation and

maintenance

** Field installed at highest point in

system on return line to pumps

*** Locate at tops of all risers and

any intermediate system high points

DPN001430

Rev. 0