Page: 52

Service Guide ML520/521

Chapter 2 Principles of Operation

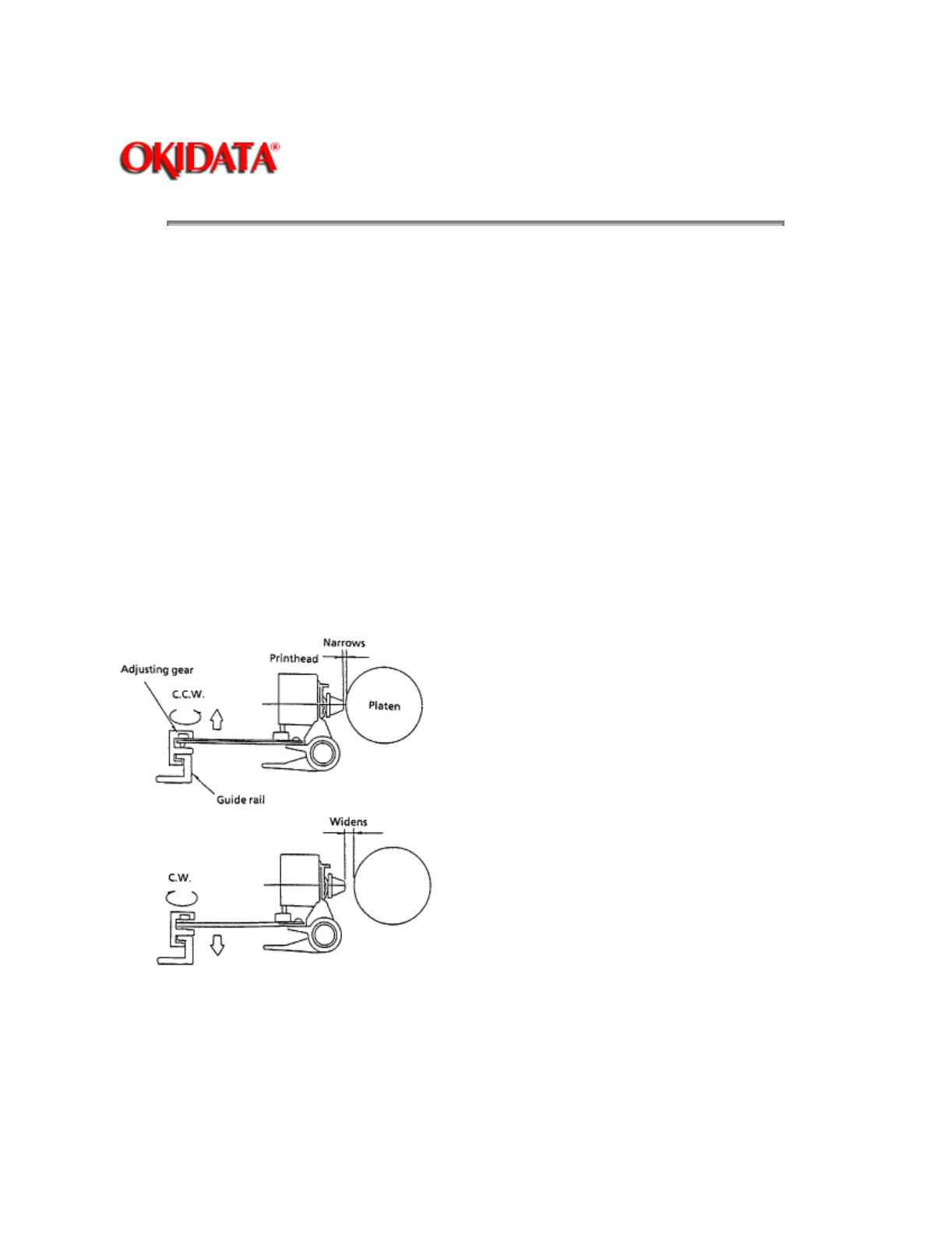

2.2.03 Head Gap Mechanism

The head gap is automatically set for the thickness of the medium loaded in the printer. In the case of

envelopes, where the medium thickness varies as the printhead moves along the platen, the strike force

of the pins changes to compensate for the differences in thickness.

Head Gap Setting Operation

Once printing starts, the space motor rotates the ribbon gear, causing idle gear C to turn the change gear.

When the MPU requests a change in the head gap setting, the GAP-P signal causes the armature (which

is holding the change gear) to be attracted to the pranger magnet. The gap reset spring can now push the

change gear so it contacts the gap change gear.

The rotation of the gap change gear causes idle gear D to turn the adjust gear. The adjust gear turns the

adjusting screw, resulting in a new head gap setting.

NOTE:

As the adjusting screw turns counter-clockwise, the gap narrows.

As the adjusting screw turns clockwise, the gap widens.

There is a cam at each setting of the gap change gear. When the change gear is at the top of the cam,

the change gear disengages from the gap change gear. At this time, the armature resets, changing the

head gap by one setting.

The head gap is modified in .06 mm units for each range setting.