724-746-5500 | blackbox.com

724-746-5500 | blackbox.com

Page 29

Chapter 2: Installation

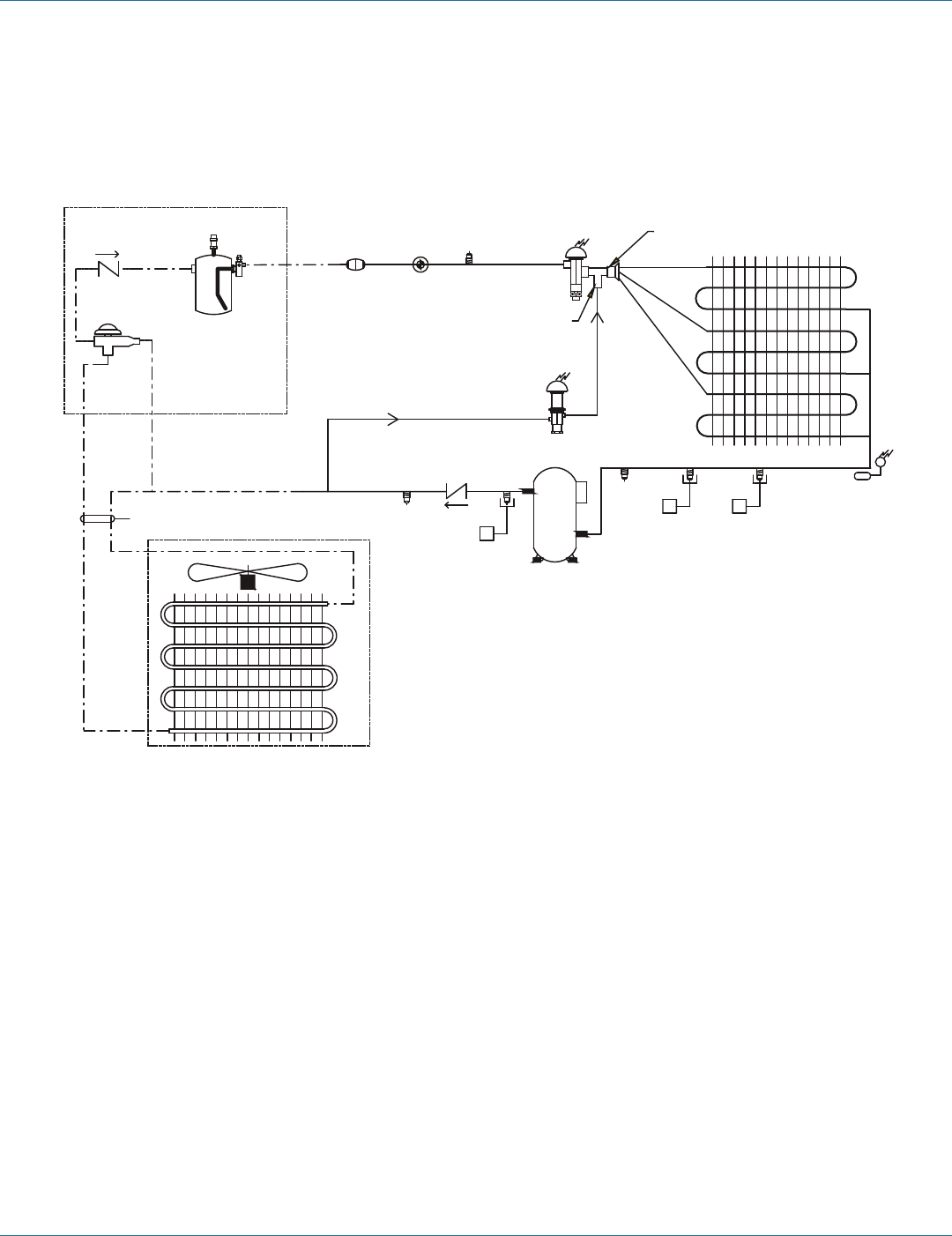

2.8 Split Air-Cooled Systems

Split air-cooled systems with a remote condenser will require field-installed refrigerant piping. All split systems are shipped with a

dry nitrogen charge of 100 psig. Release the pressure via an available stem valve or Schrader valve prior to uncapping the pipes.

Do not release the pressure until the field-installed refrigerant piping is ready to connect. Systems using a remote condenser will

require a copper liquid line and discharge line. See Figure 2-10 and refer to the IOM documentation provided with the condenser.

SIGHT

REFRIGERANT

FILTER/DRIER

REMOTE AIR COOLED CONDENSER

COMPRESSOR

HP

LIMIT SWITCH

HIGH PRESSURE

VALVE

SCHRADER

LP

VALVE

SCHRADER

LIMIT SWITCH

LOW PRESSURE

DISTRIBUTOR

THERMAL

EXPANSION

VALVE

RECEIVER

RELIEF VALVE

PRESSURE

CONTROL VALVE

HEAD PRESSURE

CHECK VALVE

CHECK VALVE

EVAPORATOR COIL

FIELD PIPING BY OTHERS

INTERCONNECTING

SCHRADER

VALVE

BODY

GLASS

OPTIONAL COMPONENTS FOR FLOODED HEAD PRESSURE CONTROL

ELECTRONIC

TEMPERATURE

SENSOR

T

PT

PRESSURE

TRANSDUCER

(OPTIONAL)

HOT GAS

REGULATOR

ASC

ELECTRONIC

Figure 2-10. Typical remote air-cooled DX piping diagram.

2.8.1 Refrigerant Piping

Refrigerant lines for the A/C unit are routed to either the top or bottom of the cabinet as specified when the Cold Row system is

ordered (see Section 2.8.1.1). The connections are made inside the cabinet. The pipe stubs are labeled; i.e. “Discharge,” “Liquid

Line.”

The refrigerant piping should be isolated by using vibration-isolating supports. Provide supports (clamps or hangers) as necessary

every 5 to 10 feet along piping runs to minimize vibration and noise transmission. To reduce vibration transmission and prevent

pipe damage when sealing openings in walls, use a soft flexible material to pack around the piping. After the piping is installed,

seal the gaps between the pipes and the entrance holes in the cabinet so air won’t leak around the pipes.

All refrigeration piping should be installed with high-temperature brazed joints. Use standard refrigeration practices for piping,

leak testing, dehydration, and charging of the refrigeration circuits. For copper-to-copper brazing, phosphorous alloy containing a

minimum of 15% silver is recommended. General-purpose silver brazing alloy with 45% silver is recommended for brazing

dissimilar metals.