724-746-5500 | blackbox.com

Page 30

724-746-5500 | blackbox.com

Chapter 2: Installation

Wrap wet rags around the pipes between the areas to be soldered and any nearby refrigeration components to keep excessive

heat from traveling through the pipe and causing damage. Clear all pipe connections of debris and prep connections for

soldering. Use only “L” or “K” grade refrigerant copper piping. Be careful not to allow solder/piping debris to get inside

refrigerant lines. Dry nitrogen should be flowing through the tubing while soldering at a rate of not less than

1.2 CFM (0.028–0.057 m

3

/minute).

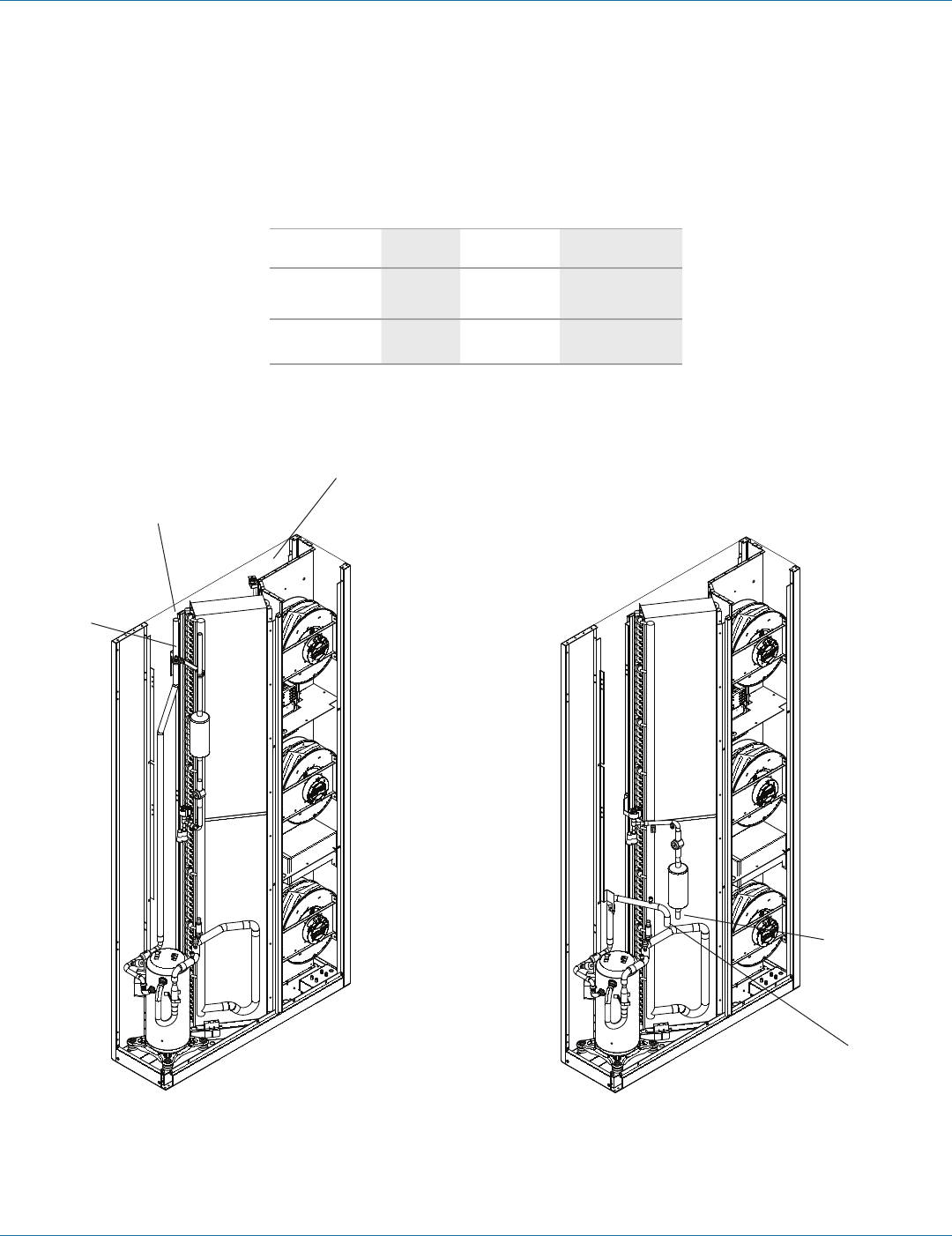

Table 2-4. Pipe connection sizes.

Model # Liquid Line Discharge Line Condensate Drain

CRDX-W-FS-12W,

CRDX-W-FS-24W

5

⁄8"

5

⁄8"

1

⁄2

"

CRDX-G-FS-12W,

CRDX-G-FS-24W

5

⁄8"

5

⁄8"

1

⁄2

"

2.8.1.1 DX Refrigerant Piping Connections

SUCTION LINE

LIQUID LINE

TOP-ACCESS PIPING

BOTTOM-ACCESS PIPING

CONDENSATE DRAIN—

1

⁄2" FPT

SUCTION LINE

LIQUID LINE

Figure 2-11. DX refrigerant piping connections.