724-746-5500 | blackbox.com

Page 38

724-746-5500 | blackbox.com

Chapter 2: Installation

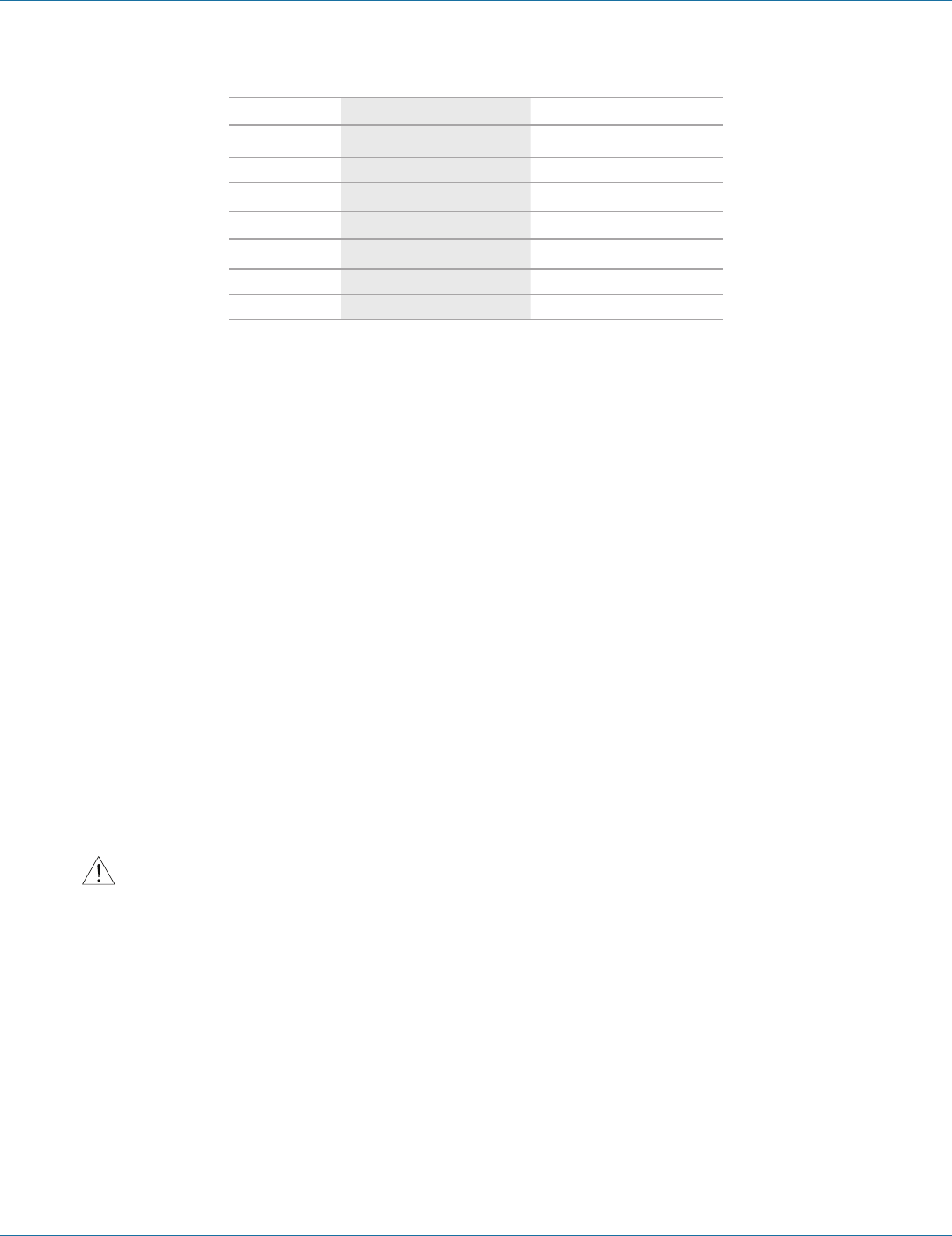

Table 2-10. Weight of R410A refrigerant (lbs./100 ft. of type L tubing).

Line Size O.D. R410A Charge (less receiver) R410A Charge (with receiver)

1

⁄2 5.88

1.27

5

⁄8 9.44

2.03

7

⁄8 19.52

4.22

1

1

⁄8 33.44

7.20

1

3

⁄8 50.95

10.97

1

5

⁄8 72.11

15.53

2

1

⁄8 158.29

34.09

Example: Estimate the amount of refrigerant required for a refrigeration circuit in a system using R410A refrigerant consisting of a

CRDX-A-FS-12KW unit connected with a

1

⁄2" x 30 foot liquid line and

7

⁄8" x 30 foot discharge line to a BB-060-SEC or BB-060-SSA

condenser.

A/C Unit = 3.9 lb.

+

1

⁄2" Liquid Line- 30 x 5.88/100 = 1.764 lb.

+

7

⁄8" Discharge Line- 30 x 4.22/100 = 1.266 lb.

+ Condenser = 2.8 lb.

Estimated Refrigerant Charge = 9.73 lb.

(Round off to nearest 0.1 lb = 9.7 lb.)

2.10.2.2 Preparing System For Charging

1. With all the system piping connections made, perform a dry nitrogen leak detection test on the system. Using dry nitrogen

only, pressurize the system to 150 psig. Ensure all service and solenoid valves are energized open and that no part of the

system is isolated from the pressurized nitrogen.

2. Since there is no refrigerant in the system to detect at this point, leaks may be detected by observing if there’s been a change

in the standing pressure after 12 hours. A significant drop in pressure (>10 psig) indicates a leak in the system that needs to be

repaired. After the system is determined to be free of leaks, you may evacuate the system.

Evacuate the System

CAUTION

A proper vacuum must be drawn on the refrigerant system to remove moisture prior to charging. If this is not done, the

refrigerant charge will combine with moisture in the pipes to form an acid that will eventually lead to compressor failure. A triple

evacuation procedure with dry nitrogen is recommended especially for systems with newly installed refrigerant piping.

NOTE: Use a vacuum pump that is capable of evacuating the entire volume of the A/C system, including newly installed or

existing piping. It is essential to use a well-maintained pump that is in good operating condition. Always ensure it contains

clean, fresh oil. Manufacturers recommend that you change the oil in the pump regularly to maintain its ability to remove

moisture.

NOTE: Use high-quality hoses that are free of defects and don’t leak. We recommend using copper tubing instead of hoses if

possible because of the low vacuum that must be attained when evacuating the system. Using short, large diameter hoses

helps reduce evacuation time.

3. After ensuring there are no leaks, relieve pressure and evacuate the entire system while maintaining all the solenoids open. Pull

an initial vacuum of 1500 microns or lower using the suction and discharge service ports.