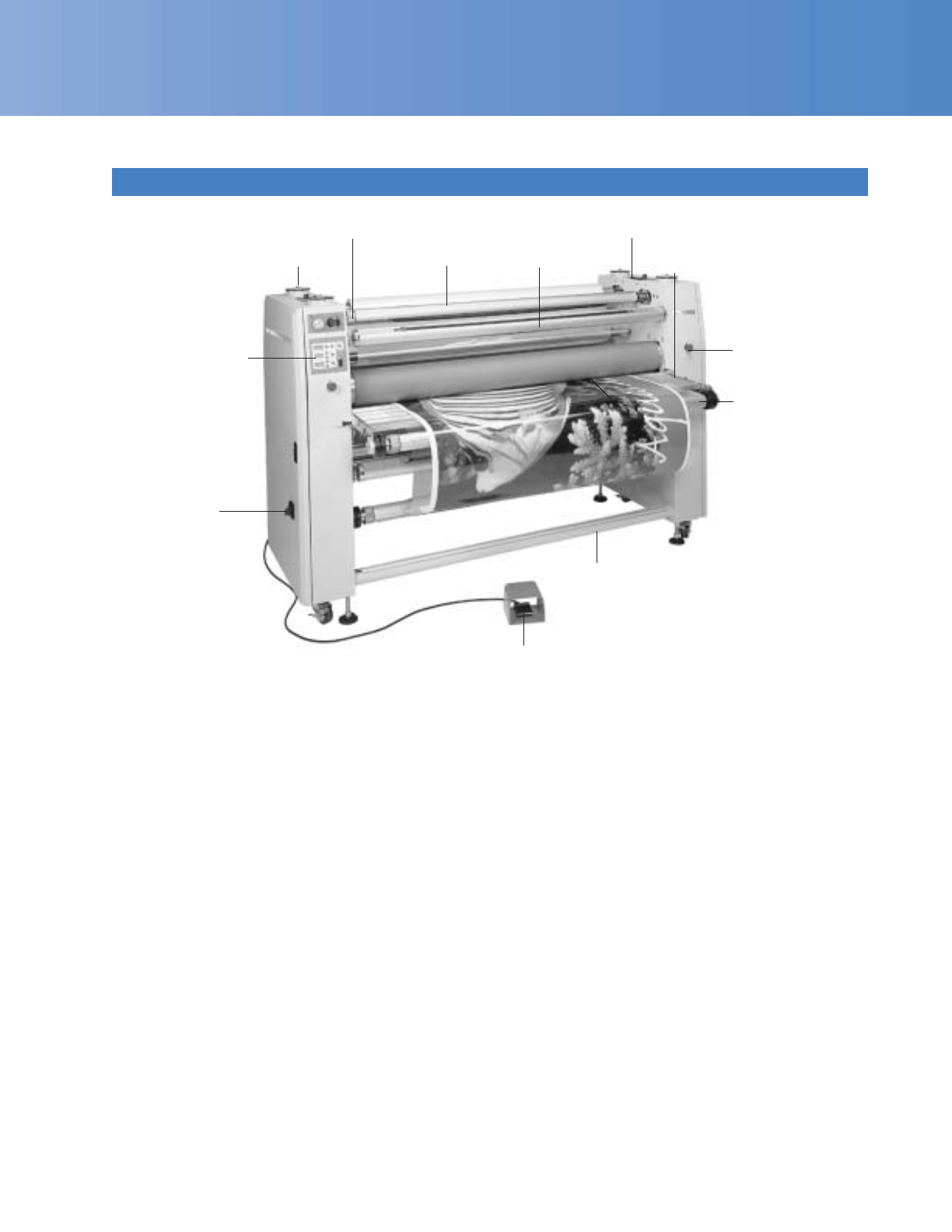

LAMINATOR FEATURES

11

Features

1. Control panel system

• For independent control of pressure, temperature and read-out of

speed and material usage.

2. Shim Wheels (4)

• Dial-in roller height adjustment for fast and accurate roller nip set

ting, which adjusts for the thickness of the material to be processed.

3. Integral Braking System

• A simple braking system with a knurled collar provides the means of

adjusting the brake tension for the films and images. Fitted on both

the roll easel shaft and the four unwind shafts.

4. Swing-Out Autogrip Unwind Shafts (4)

• Easy loading and positioning of materials. No need for manual lock

ing keys. Suitable for rolls wound onto a 3" ID core.

5 Autogrip Wind-Up Idlers (4)

• Removable shafts for winding up the release liner, finished images

or other laminate material. Use with 3" ID spare cores.

6. Top Motor Control Panels

• Controls in-feed direction and processing speed from all four

corners.

7. Interchangeable In-Feed Tables (For North America/UK):

• User preference for flat table with image guide or print guide table,

interchangeable from front to rear of laminator. For ROW the

laminator is equipped with flat tables, front and back.

8. Emergency Stop Buttons (4)

• Immediately ceases the laminator’s operation and raises the rollers.

9. Autogrip Roll Easel Shaft

• Removable media unwind shaft for images on a roll. Allows for roll-

to-roll laminating in continuous operation when used with the

wind-up idler. Interchangeable from front to rear of laminator.

10. Foot-Operated Emergency Tap Switches (2) (Auxiliary Stop)

• Immediately ceases the laminator’s operation and raises the rollers.

11. Covered Foot Switches (2)

• Allows for complete user control when initially feeding in an image.

12. Door Interlock

• Automatically shuts the laminator power off when the Door

Interlock switch is turned to the Off position.

** Bi-Directional Operation

• Eliminates the need for cool-down allowing quick application

changeovers.

** Dual-Position Cooling Tube

• Offers quick and uniform cooling for smooth, flat output during

heat-activated processes. Can be positioned above or below the chill

idlers and can be rotated to direct airflow as desired.

** Drive System

• Heavy-Duty Clutch and simplified drive system – Provides

smoother performance at all speeds and different film thickness.

** Heating Elements

• Electric High-Wattage Heating Elements and Temperature Controls

with Infrared Temperature Sensors – provide for rapid, even heating

to 275°F (135°C) and maximum accuracy.

Figure 4. Laminator Features

1

2

12

3

4

6

7

5

8

9

10

11